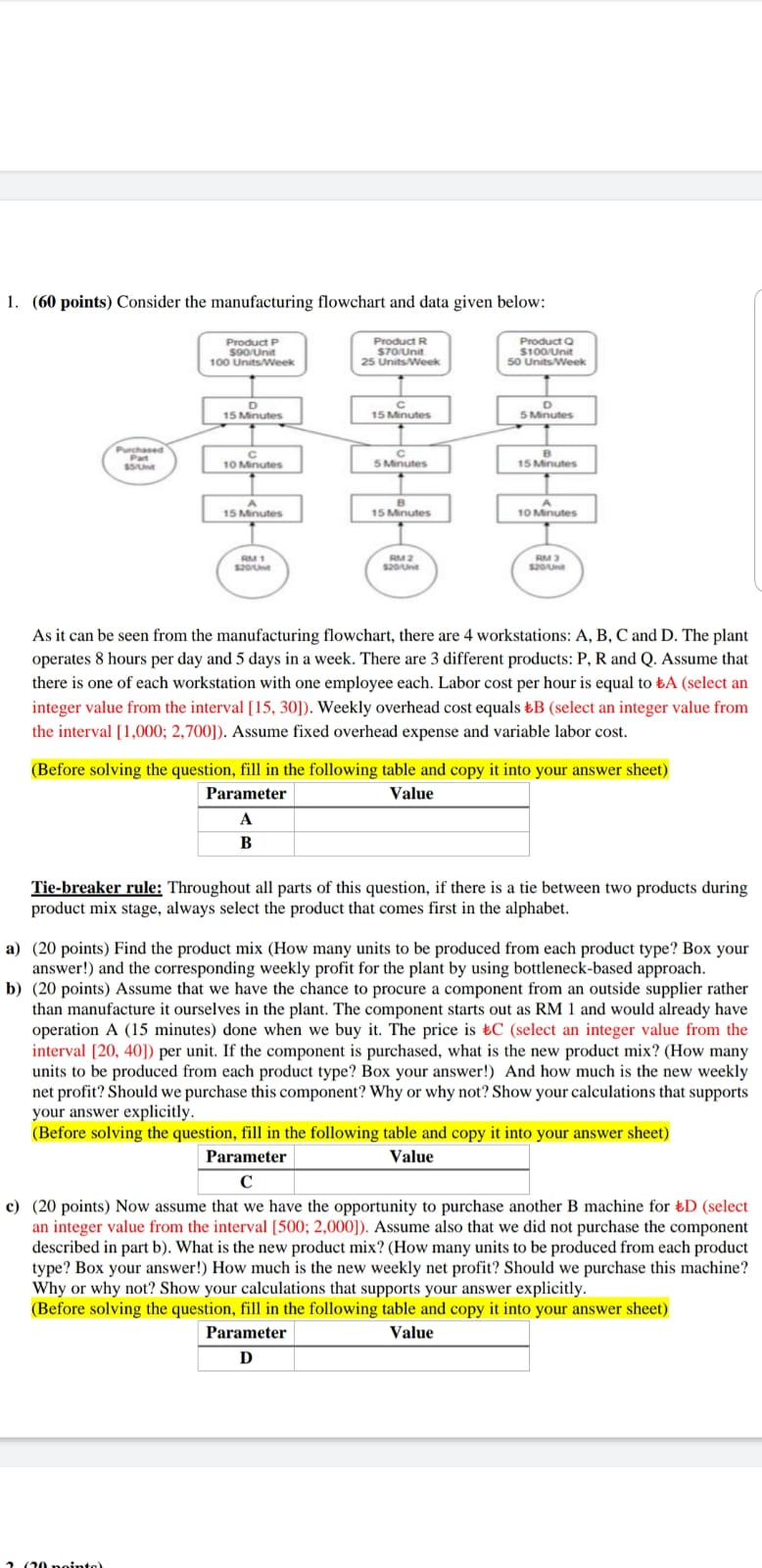

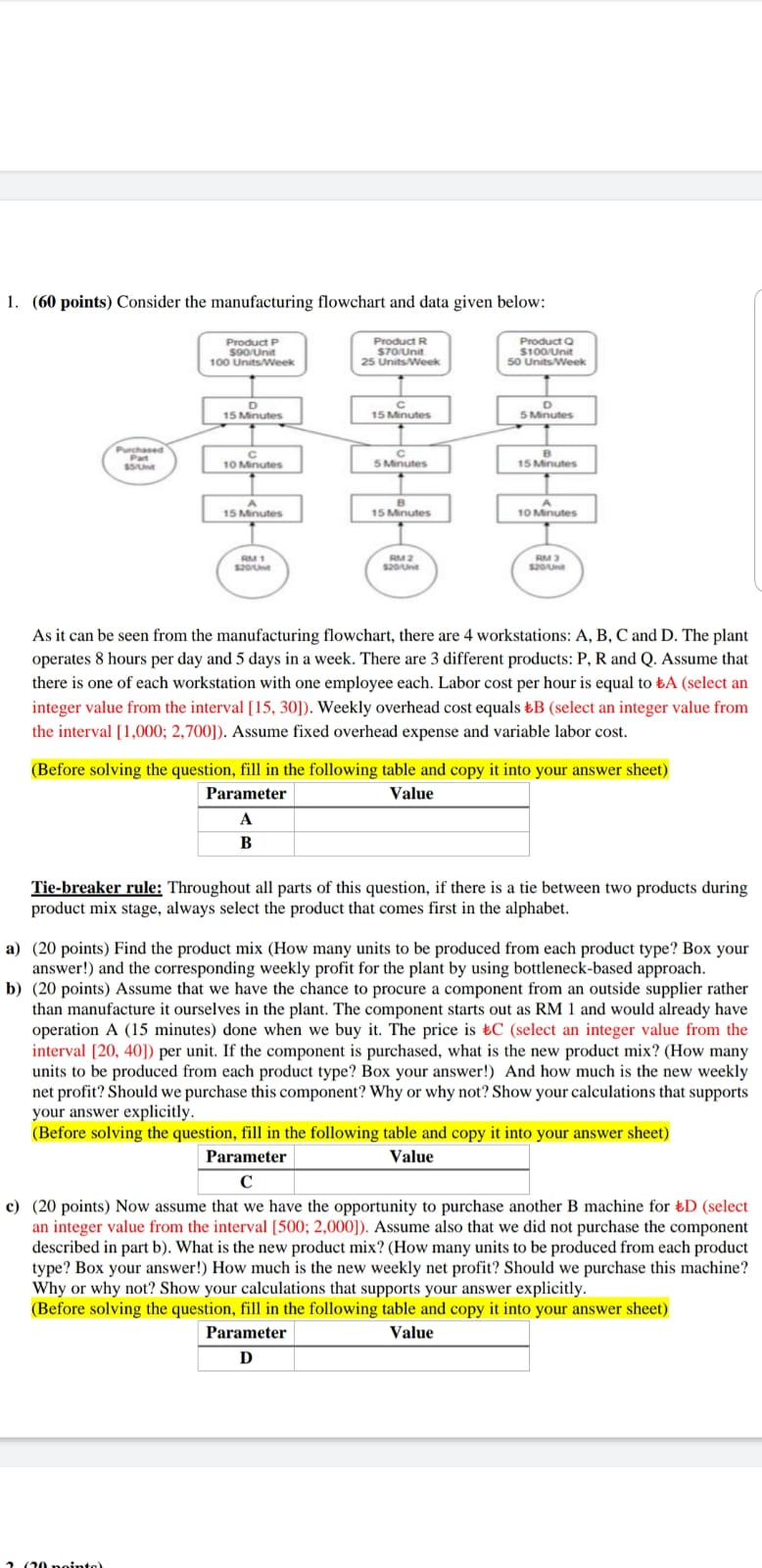

Question: 1. (60 points) Consider the manufacturing flowchart and data given below: Product P S90 Unit 100 Units/ Week Produd R $70/Unit 25 Units Week Product

1. (60 points) Consider the manufacturing flowchart and data given below: Product P S90 Unit 100 Units/ Week Produd R $70/Unit 25 Units Week Product $100/Unit 50 Units Week 15 Minutes 15 Minutes O 5 Minutes Purchased C 10 Minutes 5 Minutes B 15 Minutes 15 Minutes 15 Minutes 10 Minutes RU RM 2 20 As it can be seen from the manufacturing flowchart, there are 4 workstations: A, B, C and D. The plant operates 8 hours per day and 5 days in a week. There are 3 different products: P, R and Q. Assume that there is one of each workstation with one employee each. Labor cost per hour is equal to BA (select an integer value from the interval [15, 30]). Weekly overhead cost equals &B (select an integer value from the interval [1,000; 2,700]). Assume fixed overhead expense and variable labor cost. (Before solving the question, fill in the following table and copy it into your answer sheet) Parameter Value A B Tie-breaker rule: Throughout all parts of this question, if there is a tie between two products during product mix stage, always select the product that comes first in the alphabet. a) (20 points) Find the product mix (How many units to be produced from each product type? Box your answer!) and the corresponding weekly profit for the plant by using bottleneck-based approach. b) (20 points) Assume that we have the chance to procure a component from an outside supplier rather than manufacture it ourselves in the plant. The component starts out as RM 1 and would already have operation A (15 minutes) done when we buy it. The price is $C (select an integer value from the interval [20,40]) per unit. If the component is purchased, what is the new product mix? (How many units to be produced from each product type? Box your answer!) And how much is the new weekly net profit? Should we purchase this component? Why or why not? Show your calculations that supports your answer explicitly. (Before solving the question, fill in the following table and copy it into your answer sheet) Parameter Value c) (20 points) Now assume that we have the opportunity to purchase another B machine for D (select an integer value from the interval [500; 2,000]). Assume also that we did not purchase the component described in part b). What is the new product mix? (How many units to be produced from each product type? Box your answer!) How much is the new weekly net profit? Should we purchase this machine? Why or why not? Show your calculations that supports your answer explicitly. (Before solving the question, fill in the following table and copy it into your answer sheet) Parameter Value D 2 (20nointo) 1. (60 points) Consider the manufacturing flowchart and data given below: Product P S90 Unit 100 Units/ Week Produd R $70/Unit 25 Units Week Product $100/Unit 50 Units Week 15 Minutes 15 Minutes O 5 Minutes Purchased C 10 Minutes 5 Minutes B 15 Minutes 15 Minutes 15 Minutes 10 Minutes RU RM 2 20 As it can be seen from the manufacturing flowchart, there are 4 workstations: A, B, C and D. The plant operates 8 hours per day and 5 days in a week. There are 3 different products: P, R and Q. Assume that there is one of each workstation with one employee each. Labor cost per hour is equal to BA (select an integer value from the interval [15, 30]). Weekly overhead cost equals &B (select an integer value from the interval [1,000; 2,700]). Assume fixed overhead expense and variable labor cost. (Before solving the question, fill in the following table and copy it into your answer sheet) Parameter Value A B Tie-breaker rule: Throughout all parts of this question, if there is a tie between two products during product mix stage, always select the product that comes first in the alphabet. a) (20 points) Find the product mix (How many units to be produced from each product type? Box your answer!) and the corresponding weekly profit for the plant by using bottleneck-based approach. b) (20 points) Assume that we have the chance to procure a component from an outside supplier rather than manufacture it ourselves in the plant. The component starts out as RM 1 and would already have operation A (15 minutes) done when we buy it. The price is $C (select an integer value from the interval [20,40]) per unit. If the component is purchased, what is the new product mix? (How many units to be produced from each product type? Box your answer!) And how much is the new weekly net profit? Should we purchase this component? Why or why not? Show your calculations that supports your answer explicitly. (Before solving the question, fill in the following table and copy it into your answer sheet) Parameter Value c) (20 points) Now assume that we have the opportunity to purchase another B machine for D (select an integer value from the interval [500; 2,000]). Assume also that we did not purchase the component described in part b). What is the new product mix? (How many units to be produced from each product type? Box your answer!) How much is the new weekly net profit? Should we purchase this machine? Why or why not? Show your calculations that supports your answer explicitly. (Before solving the question, fill in the following table and copy it into your answer sheet) Parameter Value D 2 (20nointo)