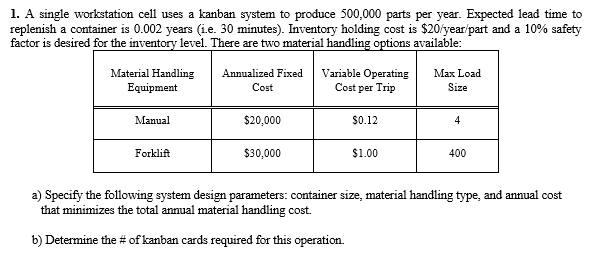

Question: 1. A single workstation cell uses a kanban system to produce 500,000 parts per year. Expected lead time to replenish a container is 0.002 years

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock