Question: 1. Fill out the Process Flow Map provided below. That is, estimate the total demand of apples, the total storage capacity of the holding bins,

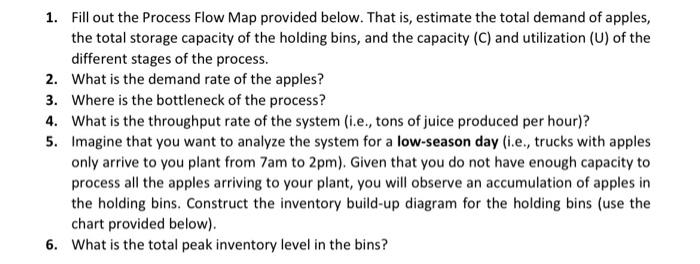

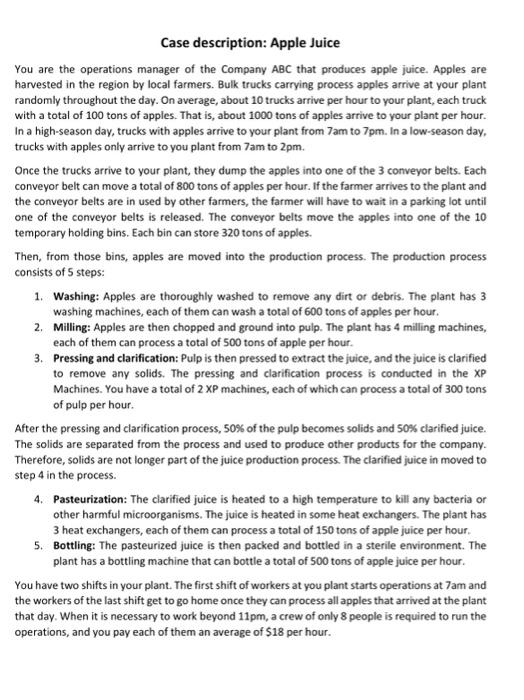

1. Fill out the Process Flow Map provided below. That is, estimate the total demand of apples, the total storage capacity of the holding bins, and the capacity (C) and utilization (U) of the different stages of the process. 2. What is the demand rate of the apples? 3. Where is the bottleneck of the process? 4. What is the throughput rate of the system (i.e., tons of juice produced per hour)? 5. Imagine that you want to analyze the system for a low-season day (i.e., trucks with apples only arrive to you plant from 7am to 2pm ). Given that you do not have enough capacity to process all the apples arriving to your plant, you will observe an accumulation of apples in the holding bins. Construct the inventory build-up diagram for the holding bins (use the chart provided below). 6. What is the total peak inventory level in the bins? Case description: Apple Juice You are the operations manager of the Company ABC that produces apple juice. Apples are harvested in the region by local farmers. Bulk trucks carrying process apples arrive at your plant randomly throughout the day. On average, about 10 trucks arrive per hour to your plant, each truck with a total of 100 tons of apples. That is, about 1000 tons of apples arrive to your plant per hour. In a high-season day, trucks with apples arrive to your plant from 7 am to 7pm. In a low-season day, trucks with apples only arrive to you plant from 7 am to 2pm. Once the trucks arrive to your plant, they dump the apples into one of the 3 conveyor belts. Each conveyor belt can move a total of 800 tons of apples per hour. If the farmer arrives to the plant and the conveyor belts are in used by other farmers, the farmer will have to wait in a parking lot until one of the conveyor belts is released. The conveyor belts move the apples into one of the 10 temporary holding bins. Each bin can store 320 tons of apples. Then, from those bins, apples are moved into the production process. The production process consists of 5 steps: 1. Washing: Apples are thoroughly washed to remove any dirt or debris. The plant has 3 washing machines, each of them can wash a total of 600 tons of apples per hour. 2. Milling: Apples are then chopped and ground into pulp. The plant has 4 milling machines, each of them can process a total of 500 tons of apple per hour. 3. Pressing and clarification: Pulp is then pressed to extract the juice, and the juice is clarified to remove any solids. The pressing and clarification process is conducted in the XP Machines. You have a total of 2 XP machines, each of which can process a total of 300 tons of pulp per hour. After the pressing and clarification process, 50% of the pulp becomes solids and 50% clarified juice. The solids are separated from the process and used to produce other products for the company. Therefore, solids are not longer part of the juice production process. The clarified juice in moved to step 4 in the process. 4. Pasteurization: The clarified juice is heated to a high temperature to kill any bacteria or other harmful microorganisms. The juice is heated in some heat exchangers. The plant has 3 heat exchangers, each of them can process a total of 150 tons of apple juice per hour. 5. Bottling: The pasteurized juice is then packed and bottled in a sterile environment. The plant has a bottling machine that can bottle a total of 500 tons of apple juice per hour. You have two shifts in your plant. The first shift of workers at you plant starts operations at 7 am and the workers of the last shift get to go home once they can process all apples that arrived at the plant that day. When it is necessary to work beyond 11pm, a crew of only 8 people is required to run the operations, and you pay each of them an average of $18 per hour

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts