Question: 1. Identify Process and elaborate the activities 2. Draw Process Flow Diagrams in MS VISIO or any cross-functional Visio online or any cross-functional online and

1. Identify Process and elaborate the activities 2. Draw Process Flow Diagrams in MS VISIO or any cross-functional Visio online or any cross-functional online and use the same shape

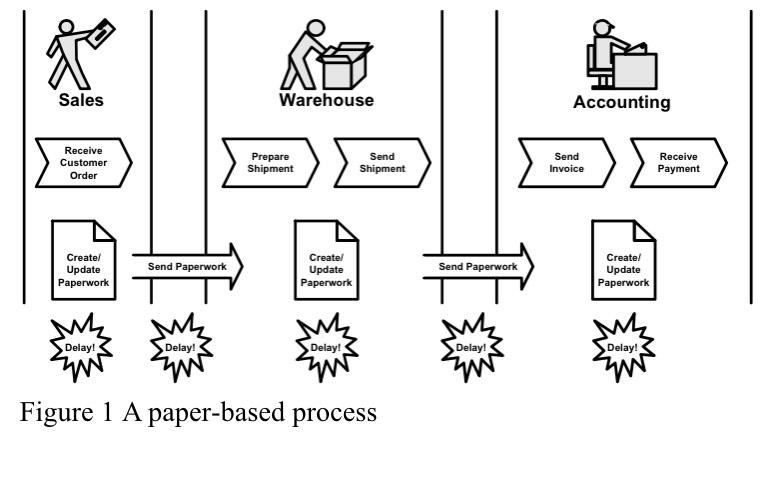

1. Paper-based process

In many organizations, the coordination of work across the process is not very efcient, is time consuming, and results in numerous problems: delays, excess inventory, and lack ofvisibility across the process. Lets take a closer look at each ofthese problems.

a) Delays in Executing the Process

The rst consequence of poor coordination is delays caused by the time it takes to communicate information among different parts of the process. When an organization performs thiscoordination manuallyfor example, by using the multi partsales order document in our fulllment processdelays areinevitable. Further, requiring employees to complete, forward, and le paperwork wastes time that they could be devoting to their tasks. Finally, in addition to causing delays, this paperwork constitutes a signicant cost incurred by the company. Figure 1illustrates the two sources of delays in the fulllment process: delays due to the need to maintain paperwork and delays in sending the paperwork to other functions. Delays occur in the form of increased lead times (e.g., how far in advance a company must plan to obtain raw materials from its suppliers) and cycle times (i.e., the amount of time needed to produce a product or process a customer order). Increased lead times can cause a company to have an insufcient inventory of material when it is needed. Increased cycle times can prevent the company from producing goods and lling customer orders in a timely manner. Both of these problems can lead to lost sales.

a) Excess Inventory

The second consequence of poor coordination among functions is excess inventory. Companies that are plagued by delays and poor communication frequently tend to cover themselves by creating a buffer of inventory. Thus, the factory manager will keep a little extra raw material on hand, just in case the purchasing process is delayed (which history has shown is often the case), the warehouse manager will stockpile a little extra inventory of raw material and nished goods, just in case the purchasing process and the production process are delayed, and so on. If all the groups involved in the process pile up extra inventory, the result will be an excessiveand costlyamount of extra just in case inventory for the organization.

a) Lack of Visibility across Processes

A third consequence of poor coordination is a lack of visibility across the process. That is, the people involved in the process do not have information about (1) the status of the process in other parts of the organization and/or how well the process is performing over time. Typically, the paperwork and information about process steps are not readily available to people in other departments. Referring back to Figure 1.5, for instance, in the fulllment process, once the sales person sends the customer order to the warehouse, the sales person receives no follow-up information regarding the subsequent steps in the process. As a result, if the customer calls to inquire about the status of the order, the salesperson has to call the warehouse or the accounting department to track down this information. A costly consequence of not having good visibility across the organization is illustrated in the case of Nike (see Business Processes in Practice1-4).In this case, the problems were caused by a lack of visibility across multiple processes, not just across one process. The root cause of these three problems is the tendency to view work in terms of functional silos rather than in terms of cross-functional processes. Because the people in each functional area are focused on their own world, they do not easily see how signicant the negative consequences of the little delays, small mistakes, and excess inventory can be to the process or to the organization as a whole. At the process level,small delays can accumulate to signicantly extend the timerequired to ll a customer order or acquire raw materials. Similarly, at the organizational level, small quantities of extra inventory can add up to cost the organization signicant amounts of money in terms of storage and opportunity costs.

Figure 1 A paper-based process

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts