Question: 1. Sheet pile retaining wall systems: 1.1. Explain what the process is for installing and removing a sheet pile retaining wall system. 1.2. What are

1. Sheet pile retaining wall systems:

1.1. Explain what the process is for installing and removing a sheet pile retaining wall system.

1.2. What are some of the benefits and limitations of this system? Justify your answer in a complete sentence.

2. Soldier pile and lagging retaining wall systems:

2.1. Describe what a soldier pile and lagging retaining wall system is. How does each part (soldier pile vs. lagging) function?

3. Soil Nail vs. Soil tieback:

3.1. What is the primary difference between a soil nail and a soil tieback?

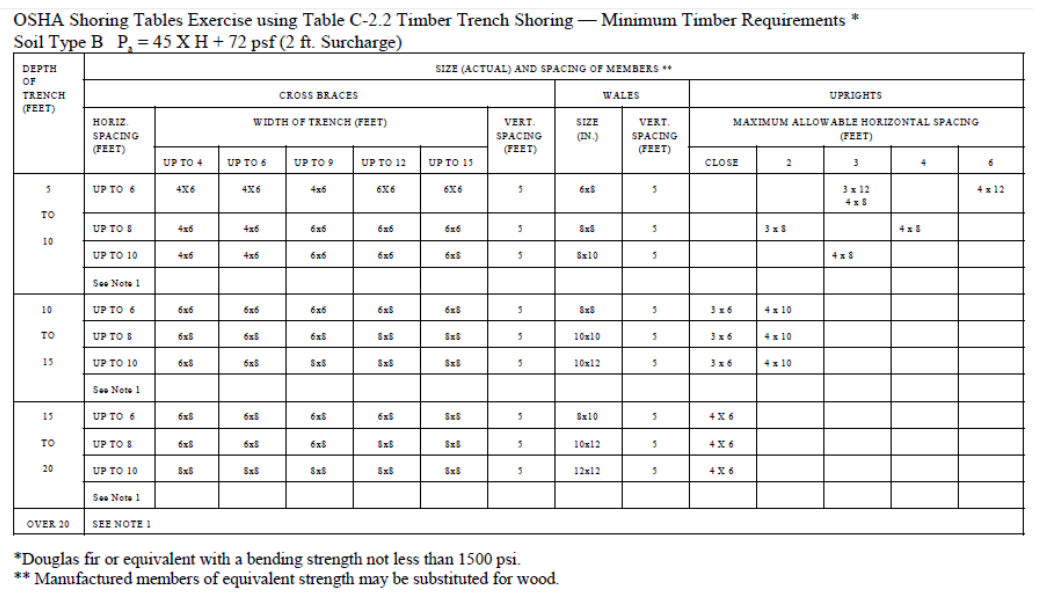

4. OSHA Timber Trench Shoring Tables: Using the attached OSHA Timber Trench Shoring Table C-2.2 (attached) design three alternate options for a wood shoring system in

Type B soil for a trench that is

17 ft deep and

7 ft wide.

4.1. Describe each completely. Name them Alternate #1, #2 and #3.

5. Secant pile wall: (Use complete sentences.)

5.1. Explain what a secant pile wall system is.

5.2. Describe the process for installation of a secant pile wall.

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts