Question: 1. The Bloomington Bike Company produces two models: the Basic and the Supra. Herb Hoosier, the owner, plans to assemble 10 Basics and 12Suprasin

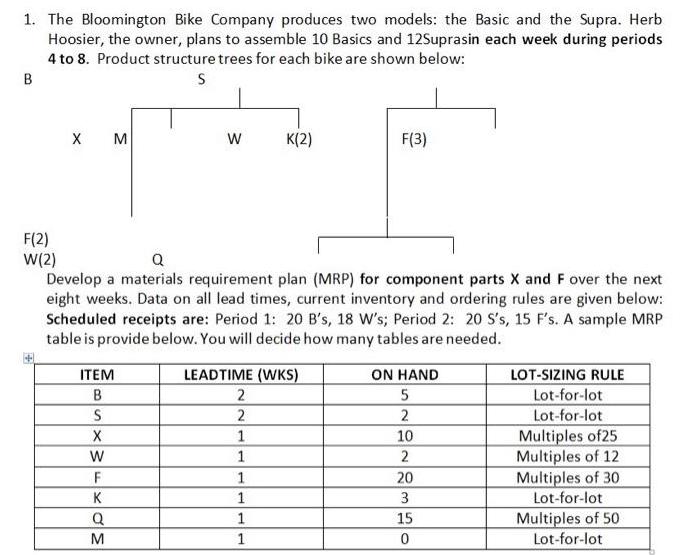

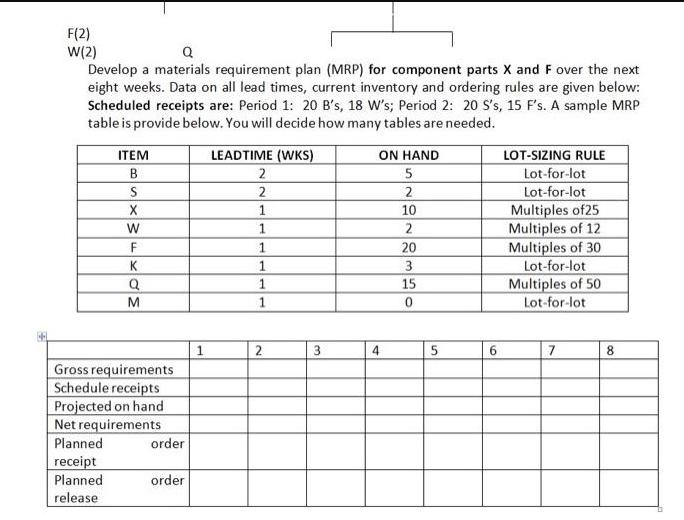

1. The Bloomington Bike Company produces two models: the Basic and the Supra. Herb Hoosier, the owner, plans to assemble 10 Basics and 12Suprasin each week during periods 4 to 8. Product structure trees for each bike are shown below: B S F(2) W(2) X M W ITEM B S X W F K Q M K(2) Q Develop a materials requirement plan (MRP) for component parts X and F over the next eight weeks. Data on all lead times, current inventory and ordering rules are given below: Scheduled receipts are: Period 1: 20 B's, 18 W's; Period 2: 20 S's, 15 F's. A sample MRP table is provide below. You will decide how many tables are needed. LEADTIME (WKS) 2 2 1 1 1 1 1 1 F(3) ON HAND 5 2 10 2 20 3 15 0 LOT-SIZING RULE Lot-for-lot Lot-for-lot Multiples of 25 Multiples of 12 Multiples of 30 Lot-for-lot Multiples of 50 Lot-for-lot F(2) W(2) Q Develop a materials requirement plan (MRP) for component parts X and F over the next eight weeks. Data on all lead times, current inventory and ordering rules are given below: Scheduled receipts are: Period 1: 20 B's, 18 W's; Period 2: 20 S's, 15 F's. A sample MRP table is provide below. You will decide how many tables are needed. LEADTIME (WKS) 2 2 1 1 ITEM B S X W F K Q M Gross requirements Schedule receipts Projected on hand Net requirements Planned receipt Planned release order order 1 1 1 1 1 2 3 ON HAND 5 2 10 2 20 3 15 0 4 6 LOT-SIZING RULE Lot-for-lot Lot-for-lot Multiples of25 Multiples of 12 Multiples of 30 Lot-for-lot Multiples of 50 Lot-for-lot 7 8

Step by Step Solution

There are 3 Steps involved in it

Steps to create MRP 1 Enter the gross requirement as per Master Planning Schedule MPS Gross requirement of components is calculated as per usage in pa... View full answer

Get step-by-step solutions from verified subject matter experts