Question: 1. Using a fixed order quantity = 150 for the lot sizing rule 2. Using Lot-for-Lot as the lot sizing rule 3. Using POQ =

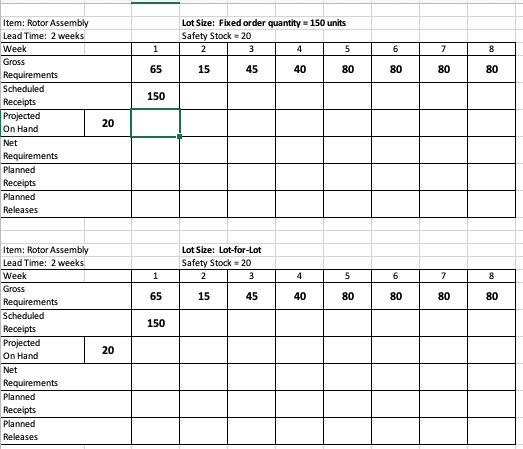

1. Using a fixed order quantity = 150 for the lot sizing rule

2. Using Lot-for-Lot as the lot sizing rule

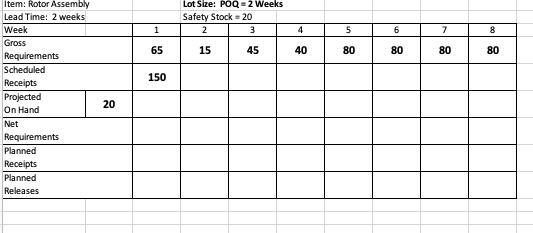

3. Using POQ = 2 weeks as the lot sizing rule.

I have modified the problem in the book, by also requiring safety stock of 20 units for this item. You can start with the blank tables in the file MRP Homework 2.xlsx. All the information you need is in this file. Just complete the three MRP tables using the three different lot sizing rules.

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts