Question: 1. What is the problem about? 2. Which methods have been used? 3. What do you understand from figures? 4. What kind of solution have

1. What is the problem about? 2. Which methods have been used? 3. What do you understand from figures? 4. What kind of solution have been found? 5. What is the result of this project/case study?

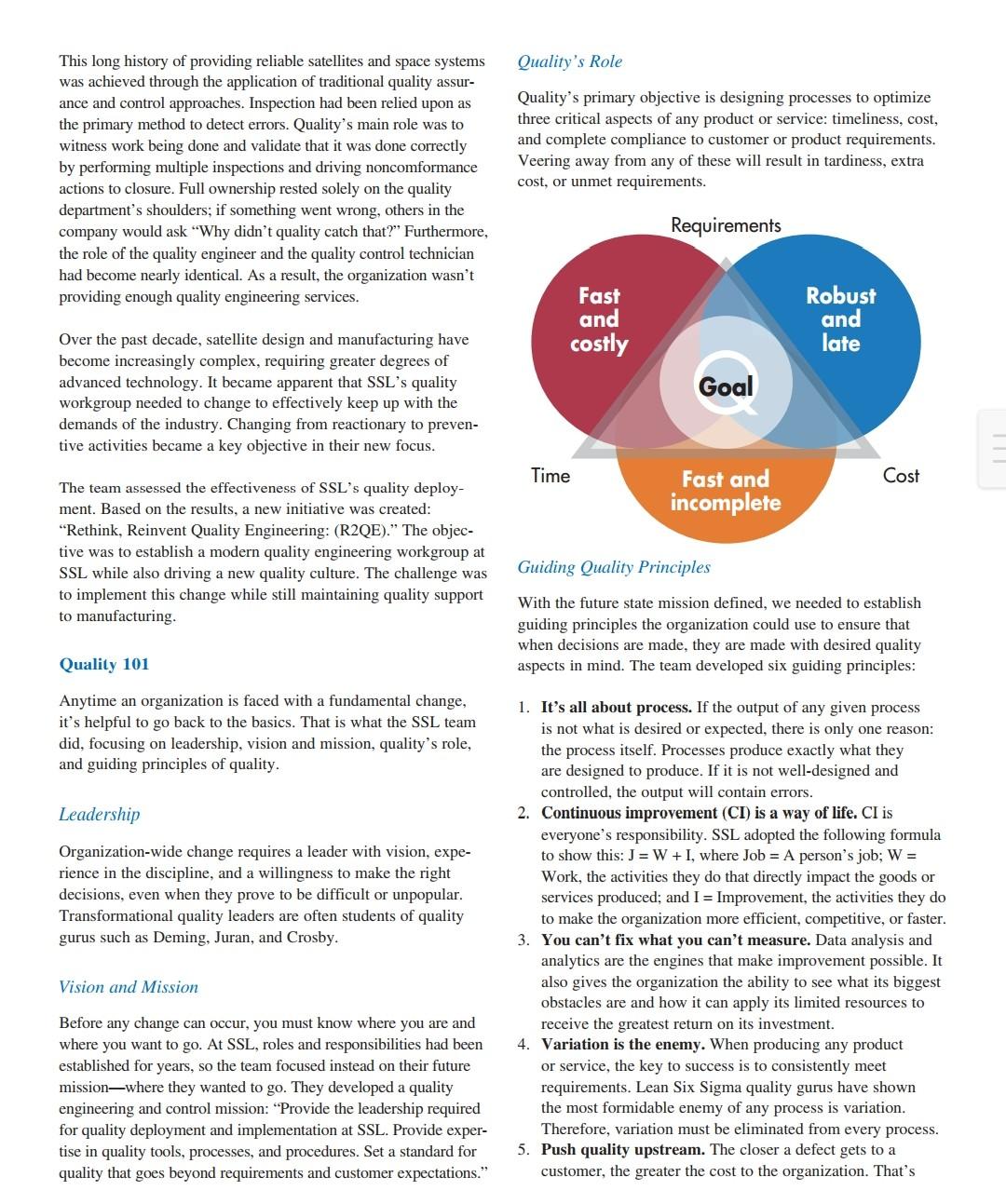

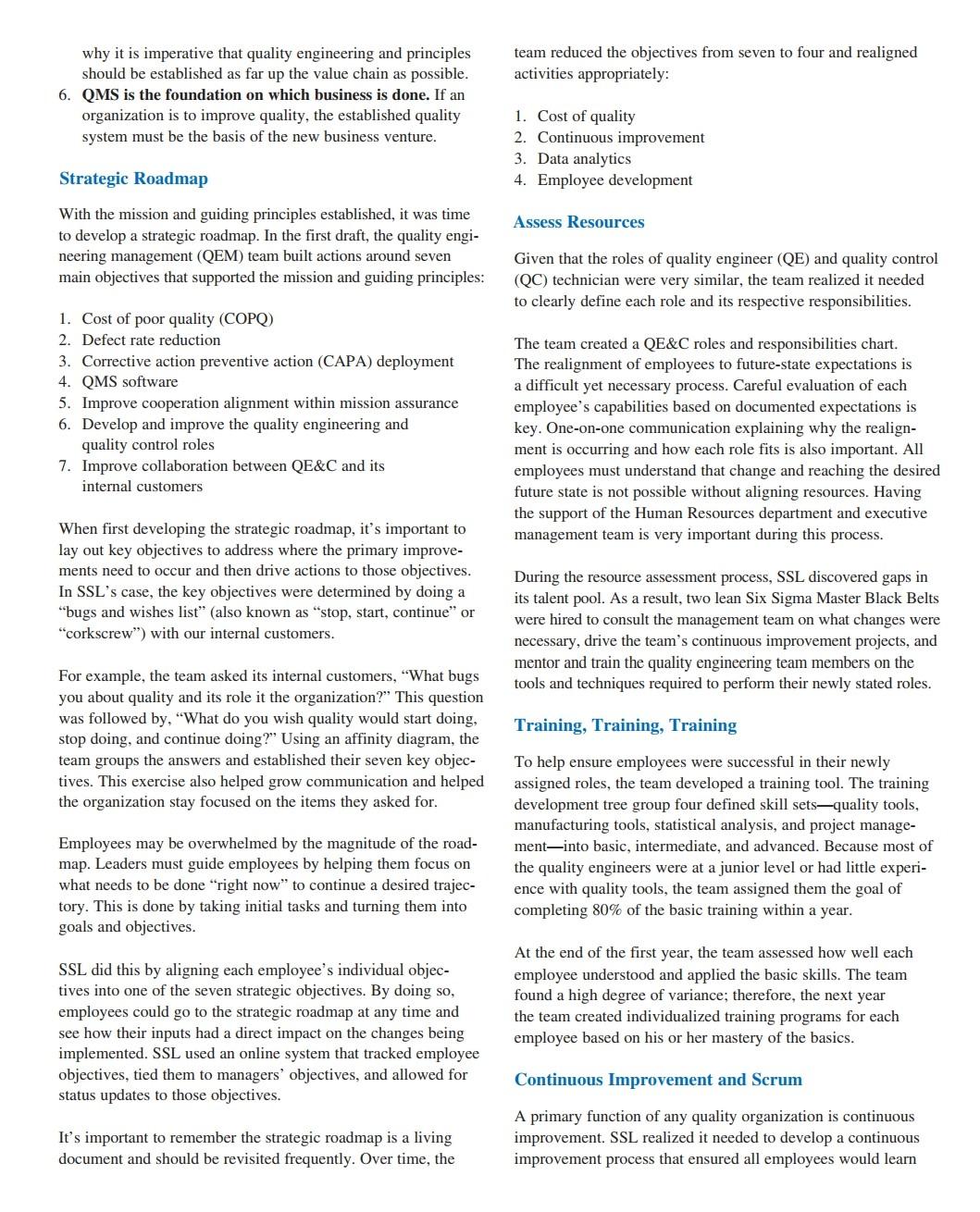

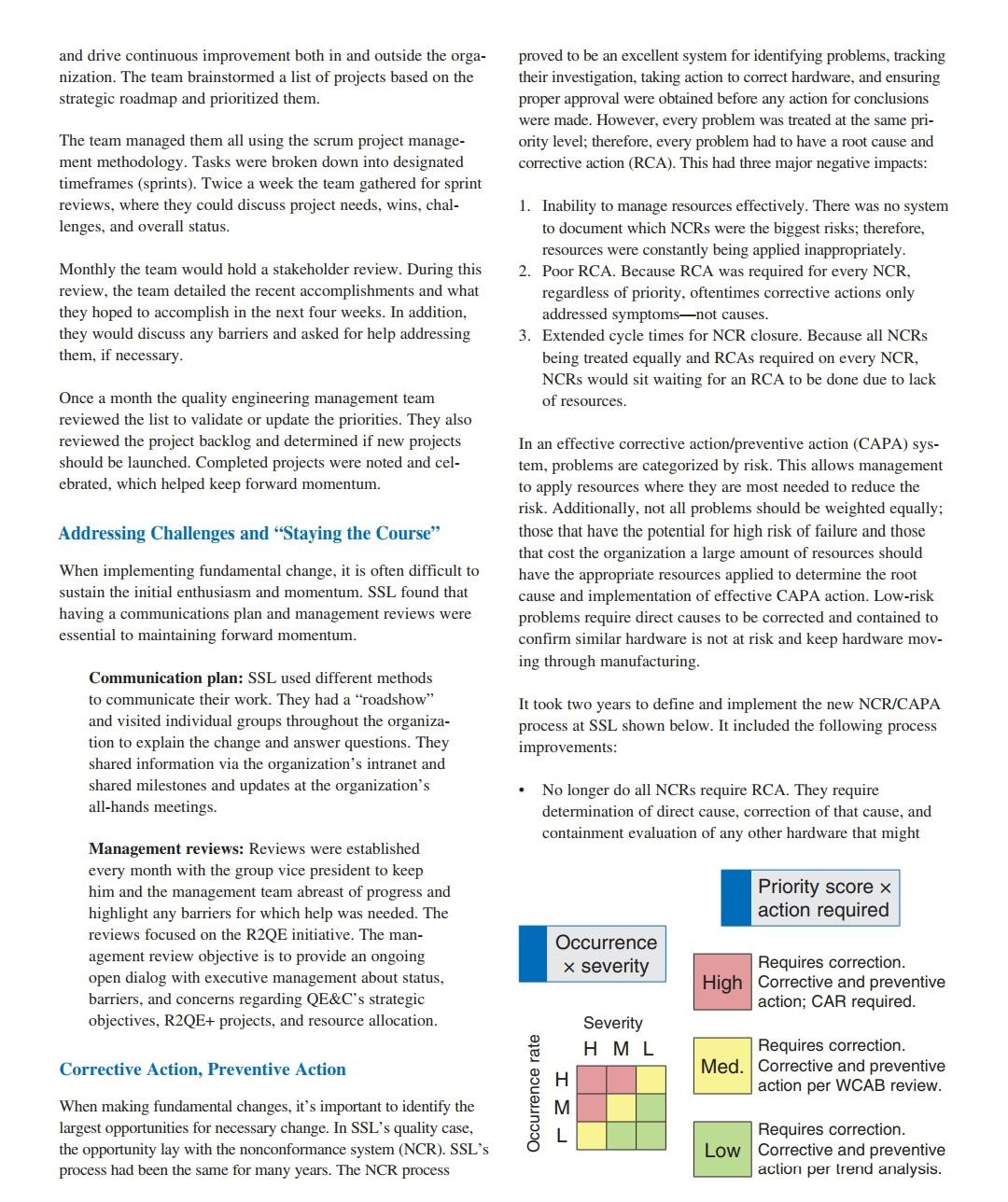

Quality Redesign at SSL by Mark Seay In the Beginning: SSL and Quality SSL? SSL is a global leader in integrated space technologies, delivering advanced systems for commu- nications, exploration, data gathering, and next-generation services. Based in the United States, the organization designs and manufactures innovative spacecraft and space-related systems with an advanced product line that includes high-powered geostationary satellites, state-of-the-art small satel- lites, and sophisticated robotics and automation solutions for remote operations. At a Glance ... SSL has built more of the geostationary communications satellites currently in service than any other manufacturer. This includes spacecraft for direct-to-home television, video content distribution, broad- band internet, and mobile communications. SSL also offers highly sophisticated in-orbit servicing for government and commercial satellites, and end-to-end solutions for observing the earth and rapidly translating vast amounts of data into useable information. SSL, a global leader in integrated space technologies, underwent a complete redesign of its quality organization by reinventing its purpose and role in the company. These changes were not only foundational in nature, they required a significant cultural shift by the quality organization and by company-wide management. This case study details the fundamentals and processes that were used to achieve this level of change, which may be helpful for other organizations undergoing or contemplating changes to their structure and processes. Quality's Role This long history of providing reliable satellites and space systems was achieved through the application of traditional quality assur- ance and control approaches. Inspection had been relied upon as the primary method to detect errors. Quality's main role was to witness work being done and validate that it was done correctly by performing multiple inspections and driving noncomformance actions to closure. Full ownership rested solely on the quality department's shoulders, if something went wrong, others in the company would ask "Why didn't quality catch that?" Furthermore, the role of the quality engineer and the quality control technician had become nearly identical. As a result, the organization wasn't providing enough quality engineering services. Quality's primary objective is designing processes to optimize three critical aspects of any product or service: timeliness, cost, and complete compliance to customer or product requirements. Veering away from any of these will result in tardiness, extra cost, or unmet requirements. Requirements Fast and costly Robust and late Over the past decade, satellite design and manufacturing have become increasingly complex, requiring greater degrees of advanced technology. It became apparent that SSL's quality workgroup needed to change to effectively keep up with the demands of the industry. Changing from reactionary to preven- tive activities became a key objective in their new focus. Goal Time Cost Fast and incomplete The team assessed the effectiveness of SSL's quality deploy- ment. Based on the results, a new initiative was created: Rethink, Reinvent Quality Engineering: (R2QE)." The objec- tive was to establish a modern quality engineering workgroup at SSL while also driving a new quality culture. The challenge was to implement this change while still maintaining quality support to manufacturing. Guiding Quality Principles With the future state mission defined, we needed to establish guiding principles the organization could use to ensure that when decisions are made, they are made with desired quality aspects in mind. The team developed six guiding principles: Quality 101 Anytime an organization is faced with a fundamental change, it's helpful to go back to the basics. That is what the SSL team did, focusing on leadership, vision and mission, quality's role, and guiding principles of quality. Leadership Organization-wide change requires a leader with vision, expe- rience in the discipline, and a willingness to make the right decisions, even when they prove to be difficult or unpopular. Transformational quality leaders are often students of quality gurus such as Deming, Juran, and Crosby. 1. It's all about process. If the output of any given process is not what is desired or expected, there is only one reason: the process itself. Processes produce exactly what they are designed to produce. If it is not well-designed and controlled, the output will contain errors. 2. Continuous improvement (CI) is a way of life. CI is everyone's responsibility. SSL adopted the following formula to show this: J = W + I, where Job = A person's job; W = Work, the activities they do that directly impact the goods or services produced; and I = Improvement, the activities they do to make the organization more efficient, competitive, or faster. 3. You can't fix what you can't measure. Data analysis and analytics are the engines that make improvement possible. It also gives the organization the ability to see what its biggest obstacles are and how it can apply its limited resources to receive the greatest return on its investment. 4. Variation is the enemy. When producing any product or service, the key to success is to consistently meet requirements. Lean Six Sigma quality gurus have shown the most formidable enemy of any process is variation. Therefore, variation must be eliminated from every process. 5. Push quality upstream. The closer a defect gets to a customer, the greater the cost to the organization. That's Vision and Mission Before any change can occur, you must know where you are and where you want to go. At SSL, roles and responsibilities had been established for years, so the team focused instead on their future missionwhere they wanted to go. They developed a quality engineering and control mission: "Provide the leadership required for quality deployment and implementation at SSL. Provide exper- tise in quality tools, processes, and procedures. Set a standard for quality that goes beyond requirements and customer expectations." team reduced the objectives from seven to four and realigned activities appropriately: why it is imperative that quality engineering and principles should be established as far up the value chain as possible. 6. QMS is the foundation on which business is done. If an organization is to improve quality, the established quality system must be the basis of the new business venture. 1. Cost of quality 2. Continuous improvement 3. Data analytics 4. Employee development Strategic Roadmap Assess Resources With the mission and guiding principles established, it was time to develop a strategic roadmap. In the first draft, the quality engi- neering management (CEM) team built actions around seven main objectives that supported the mission and guiding principles: Given that the roles of quality engineer (QE) and quality control (QC) technician were very similar, the team realized it needed to clearly define each role and its respective responsibilities. 1. Cost of poor quality (COPQ) 2. Defect rate reduction 3. Corrective action preventive action (CAPA) deployment 4. QMS software 5. Improve cooperation alignment within mission assurance 6. Develop and improve the quality engineering and quality control roles 7. Improve collaboration between QE&C and its internal customers The team created a QE&C roles and responsibilities chart. The realignment of employees to future-state expectations is a difficult yet necessary process. Careful evaluation of each employee's capabilities based on documented expectations is key. One-on-one communicatio explaining why the realign- ment is occurring and how each role fits is also important. All employees must understand that change and reaching the desired future state is not possible without aligning resources. Having the support of the Human Resources department and executive management team is very important during this process. When first developing the strategic roadmap, it's important to lay out key objectives to address where the primary improve- ments need to occur and then drive actions to those objectives. In SSL's case, the key objectives were determined by doing a "bugs and wishes list" (also known as "stop, start, continue" or "corkscrew") with our internal customers. During the resource assessment process, SSL discovered gaps in its talent pool. As a result, two lean Six Sigma Master Black Belts were hired to consult the management team on what changes were necessary, drive the team's continuous improvement projects, and mentor and train the quality engineering team members on the tools and techniques required to perform their newly stated roles. Training, Training, Training For example, the team asked its internal customers, "What bugs you about quality and its role it the organization?" This question was followed by, "What do you wish quality would start doing, stop doing, and continue doing?" Using an affinity diagram, the team groups the answers and established their seven key objec- tives. This exercise also helped grow communication and helped the organization stay focused on the items they asked for. Employees may be overwhelmed by the magnitude of the road- map. Leaders must guide employees by helping them focus on what needs to be done "right now" to continue a desired trajec- tory. This is done by taking initial tasks and turning them into goals and objectives. To help ensure employees were successful in their newly assigned roles, the team developed a training tool. The training development tree group four defined skill sets-quality tools, manufacturing tools, statistical analysis, and project manage- mentinto basic, intermediate, and advanced. Because most of the quality engineers were at a junior level or had little experi- ence with quality tools, the team assigned them the goal of completing 80% of the basic training within a year. SSL did this by aligning each employee's individual objec- tives into one of the seven strategic objectives. By doing so, employees could go to the strategic roadmap at any time and see how their inputs had a direct impact on the changes being implemented. SSL used an online system that tracked employee objectives, tied them to managers' objectives, and allowed for status updates to those objectives. At the end of the first year, the team assessed how well each employee understood and applied the basic skills. The team found a high degree of variance; therefore, the next year the team created individualized training programs for each employee based on his or her mastery of the basics. Continuous Improvement and Scrum It's important to remember the strategic roadmap is a living document and should be revisited frequently. Over time, the A primary function of any quality organization is continuous improvement. SSL realized it needed to develop a continuous improvement process that ensured all employees would learn and drive continuous improvement both in and outside the orga- nization. The team brainstormed a list of projects based on the strategic roadmap and prioritized them. proved to be an excellent system for identifying problems, tracking their investigation, taking action to correct hardware, and ensuring proper approval were obtained before any action for conclusions were made. However, every problem was treated at the same pri- ority level; therefore, every problem had to have a root cause and corrective action (RCA). This had three major negative impacts: The team managed them all using the scrum project manage- ment methodology. Tasks were broken down into designated timeframes (sprints). Twice a week the team gathered for sprint reviews, where they could discuss project needs, wins, chal- lenges, and overall status. Monthly the team would hold a stakeholder review. During this review, the team detailed the recent accomplishments and what they hoped to accomplish in the next four weeks. In addition, they would discuss any barriers and asked for help addressing them, if necessary. 1. Inability to manage resources effectively. There was no system to document which NCRs were the biggest risks; therefore, resources were constantly being applied inappropriately. 2. Poor RCA. Because RCA was required for every NCR, regardless of priority, oftentimes corrective actions only addressed symptoms-not causes. 3. Extended cycle times for NCR closure. Because all NCRS being treated equally and RCAs required on every NCR, NCRs would sit waiting for an RCA to be done due to lack of resources. Once a month the quality engineering management team reviewed the list to validate or update the priorities. They also reviewed the project backlog and determined if new projects should be launched. Completed projects were noted and cel- ebrated, which helped keep forward momentum. Addressing Challenges and "Staying the Course" When implementing fundamental change, it is often difficult to sustain the initial enthusiasm and momentum. SSL found that having a communications plan and management reviews were essential to maintaining forward momentum. In an effective corrective action/preventive action (CAPA) sys- tem, problems are categorized by risk. This allows management to apply resources where they are most needed to reduce the risk. Additionally, not all problems should be weighted equally; those that have the potential for high risk of failure and those that cost the organization a large amount of resources should have the appropriate resources applied to determine the root cause and implementation of effective CAPA action. Low-risk problems require direct causes to be corrected and contained to confirm similar hardware is not at risk and keep hardware mov- ing through manufacturing. Communication plan: SSL used different methods to communicate their work. They had a "roadshow" and visited individual groups throughout the organiza- tion to explain the change and answer questions. They shared information via the organization's intranet and shared milestones and updates at the organization's all-hands meetings. It took two years to define and implement the new NCR/CAPA process at SSL shown below. It included the following process improvements: . No longer do all NCRs require RCA. They require determination of direct cause, correction of that cause, and containment evaluation of any other hardware that might Priority score x action required Management reviews: Reviews were established every month with the group vice president to keep him and the management team abreast of progress and highlight any barriers for which help was needed. The reviews focused on the R2QE initiative. The man- agement review objective is to provide an ongoing open dialog with executive management about status, barriers, and concerns regarding QE&C's strategic objectives, R2QE+ projects, and resource allocation. Occurrence x severity Requires correction. High Corrective and preventive action; CAR required. Severity HML Corrective Action, Preventive Action Occurrence rate Requires correction. Med. Corrective and preventive action per WCAB review. IE When making fundamental changes, it's important to identify the largest opportunities for necessary change. In SSL's quality case, the opportunity lay with the nonconformance system (NCR). SSL's process had been the same for many years. The NCR process Requires correction. Low Corrective and preventive action per trend analysis. Correct and contain NCR Corrective action CAR Preventive action CAR 2 6 8 Priority Problem perception Problem definition Correct and contain Root cause Corrective action Evaluate Prevention Celebrate In year two, the team is on track to double the number of com- pleted projects. . Celebrations and Success have a similar problem. Once those steps are completed, the NCR can be closed. This change made closing NCRs much faster and removes the lien on hardware in manufacturing. The NCR tool above has been added. This tool is applied to every NCR and scored by the production team when the NCR is closed. New WCAB structure implemented. A WCAB is assigned to every manufacturing area and is made up of managers responsible for quality performance in that area. In CAPA, their focus is managing NCRS, CARS, and other quality metrics for their area. The WCABs are accountable to a newly formed Prevention Review Board (PRB) made up of executive management from all manufacturing, engineering, supply chain, and other support areas. Quality engineering's role in the WCAB process is to bring the "data" or information so appropriate decisions can be made. This includes managing the WCABs and the process to ensure it stays focused on the biggest problems at hand, and to drive decision making. The team recognizes the need for celebration to keep momen- tum going. They used a variety of awards, some based on SSL's standard recognition system. Some were handed out upon completion of each project and depend on difficultly and risk. Other incentives and celebrations included team dinners for completion of major projects, banners, and celebratory "note shredding" at the completion of sprints. The team also developed a way to learn from failures with their "Poke in the Eye" award. Done in fun, the award was given to the team members whose project failed. The team would learn what happened wrong, but also what was learned, with the understanding that "No matter how badly you mess up, it's still better than a poke in the eye." While the team strove for success, this award was given in jest but helped empower the team mem- bers to take risks and not let a fear of failure hold them back. The 80/20 Rule To mitigate anxiety during the change rollout, and to show progress, SSL utilized the 80/20 rule. Once the team believed it has 80% of any given process change ready to roll out, it did so with the understanding that iteration would come with the remaining 20% once implemented. Acknowledgments I would like to acknowledge the entire quality engineering and control team at SSL for their dedication and willingness to embrace chance. They were relentless in their desire and execution of the QE&C roadmap. I would also like to acknowledge the prod- uct assurance and mission assurance management teams. Their support and guidance of the change process has been outstanding. After the process had been run for six months, the SSL team did a retrospective and a formal audit of the process, followed by implementing any necessary corrective actions for those findings. Continuous Results About the Author Reinventing and rethinking quality is a never-ending process. Once the foundation is set, it is time to start looking outside the affected group and how the change can help the organization. SSL's quality team is doing just that. Now that their team has a solid foundation, they are looking at how they can reach outside their area. Currently they are looking at the quality department's role in the design process or new product introduction. Mark Seay has worked in the quality field for 35 years and has a technical degree in electrical engineering. During his tenure at SSL, he served as product assurance program manager for Eutelsat's first two GeoComm Satellites programs. He has since been pro- moted to quality assurance manager, designing and implementing a modern strategy for quality throughout the entire organization, including development, production, and supplier base. Using the scrum methodology, the quality team completed proj- ects worth $2 million in savings in the first year of R2QE while maintaining the necessary level of support for daily production. When Seay is not helping to put world-class technology in space, he loves to spend time with his wonderful family and enjoy his late model and classic automobilesStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts