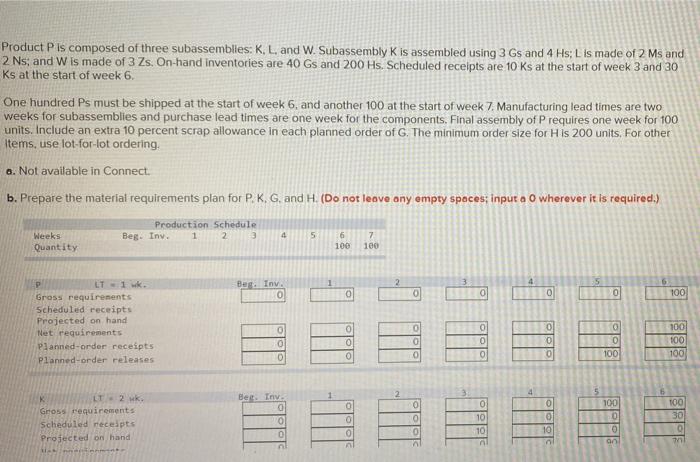

Question: 11) Please make the necessary changes.. many parts are incorrect thankyou Product Pis composed of three subassemblies: K. L. and W. Subassemblyk is assembled using

11) Please make the necessary changes.. many parts are incorrect

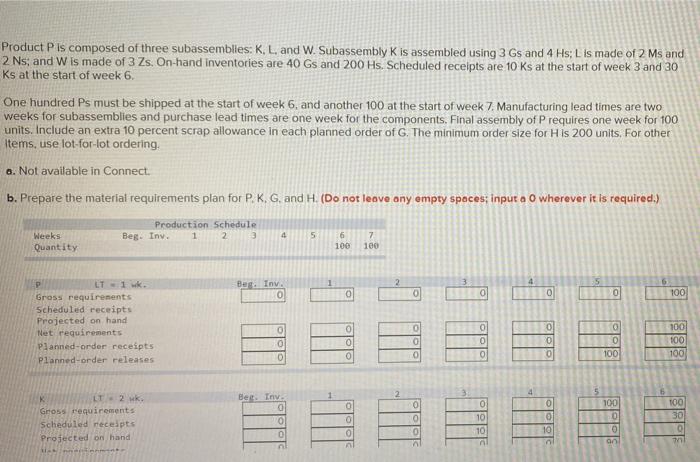

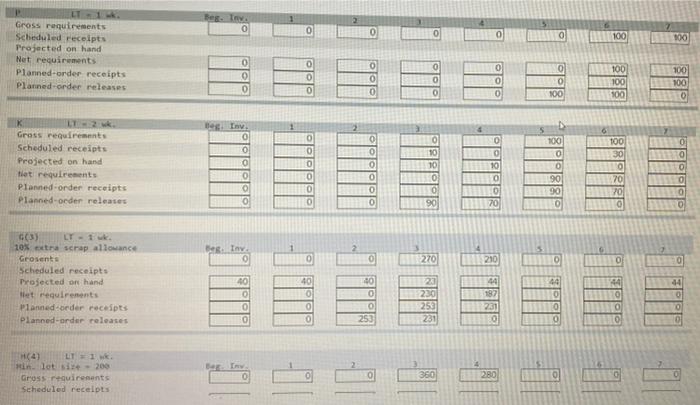

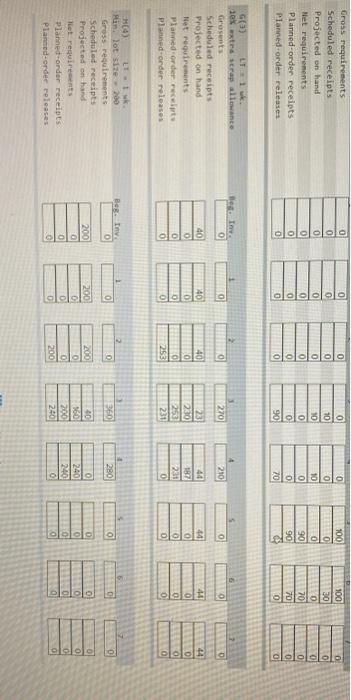

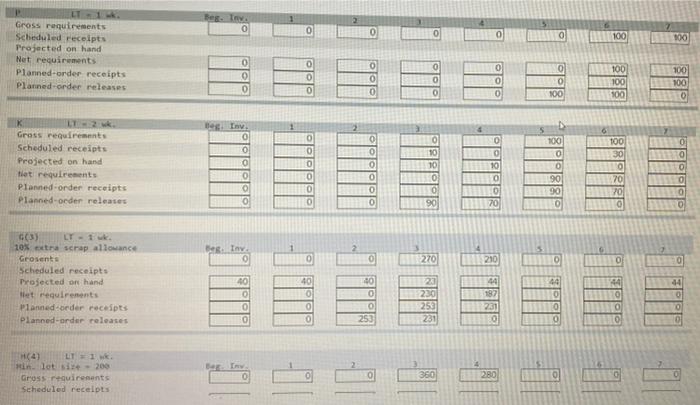

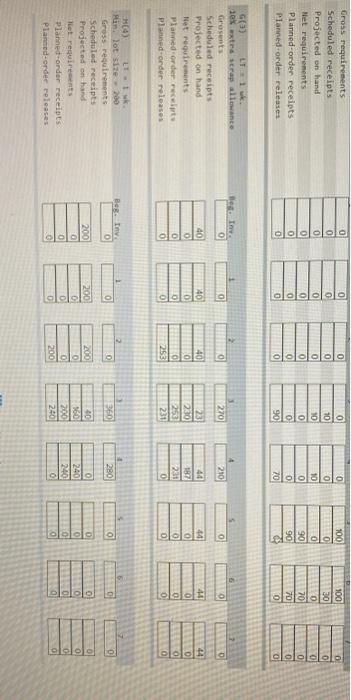

Product Pis composed of three subassemblies: K. L. and W. Subassemblyk is assembled using 3 Gs and 4 Hs; L is made of 2 Ms and 2 Ns; and W is made of 3 Zs. On-hand inventories are 40 Gs and 200 Hs. Scheduled receipts are 10 ks at the start of week 3 and 30 ks at the start of week 6. One hundred Ps must be shipped at the start of week 6, and another 100 at the start of week 7 Manufacturing lead times are two weeks for subassemblies and purchase lead times are one week for the components. Final assembly of Prequires one week for 100 units. Include an extra 10 percent scrap allowance in each planned order of G. The minimum order size for His 200 units, For other Items, use lot-for-lot ordering. 6. Not available in Connect b. Prepare the material requirements plan for P.K. G. and H. (Do not leave any empty spaces; input a o wherever it is required.) Production Schedule Beg Iny. 1 2 3 4 5 16 7 Weeks Quantity 100 100 P 2 1 Bes. Inv 0 0 0 0 100 LT-1 w Gross requirements Scheduled receipts Projected on hand Net requirements Planned-order receipts Planned-order releases 0 0 0 0 0 0 0 0 O 0 100 100 100 100 0 0 0 0 2 4 K Bee. Inv 0 LT 2. Gross requirements Scheduled receipts Projected on hand III. 0 10 0 100 0 0 100 30 0 0 10 0 nl an Beg. 2 4 0 0 0 0 0 100 300 Gross requirements Scheduled receipts Projected on hand Net requirements Planned-order receipts Planned-order releases 0 O 0 0 0 0 O 0 0 0 0 0 0 0 100 100 100 100 100 0 0 100 Bestny O 0 100 0 0 10 Grass requirements Scheduled receipts Projected on hand tiet requirements Planned-order receipts Planned-order releases TO 10 o 0 10 0 0 O O 90 100 30 0 70 20 o 0 0 0 0 0 0 0 0 O 0 70 0 90 O Bestny 0 o 270 210 O 0 (3) LT-tuk 10% tra scrap allowance Grosents Scheduled receipts Projected on hand Het requirenents Planned-order receipts Planned-order releases 40 40 44 44 23 230 44 197 O O 40 O 0 O 30 0 0 253 253 2011 0 0 0 231 0 H(4) LT=1 in lot size - 200 Gross requirements Scheduled receipts 0 360 280 10 0 0 100 100 30 10 0 olololololo OOOOOO Gross requirements Scheduled receipts Projected on hand Net requirements Planned-order receipts Planned-order releases 10 0 0 0 90 90 0 0 SO 90 70 70 0 0 0 10 O Beton O 0 0 270 210 0 0 G(S) LT de extra cap allowance Gresents Scheduled receipts Projected on hand Net requirements Planned order recipe Planned-order releases 44 44 44 40 0 40 0 40 0 23 12:30 44 0 0 0 0 0 231 0 0 0 0 253 231 0 o Best O 0 0 360 280 0 HCG) LTI Min lot size - 200 Gross requirements Scheduled receipts Projected on hand Het requirements Planned-order receipts Planned-order releases 200 200 O 200 0 0 0 O 40 160 200 240 0 0 0 240 240 0 0 o 200 0 0

thankyou

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock