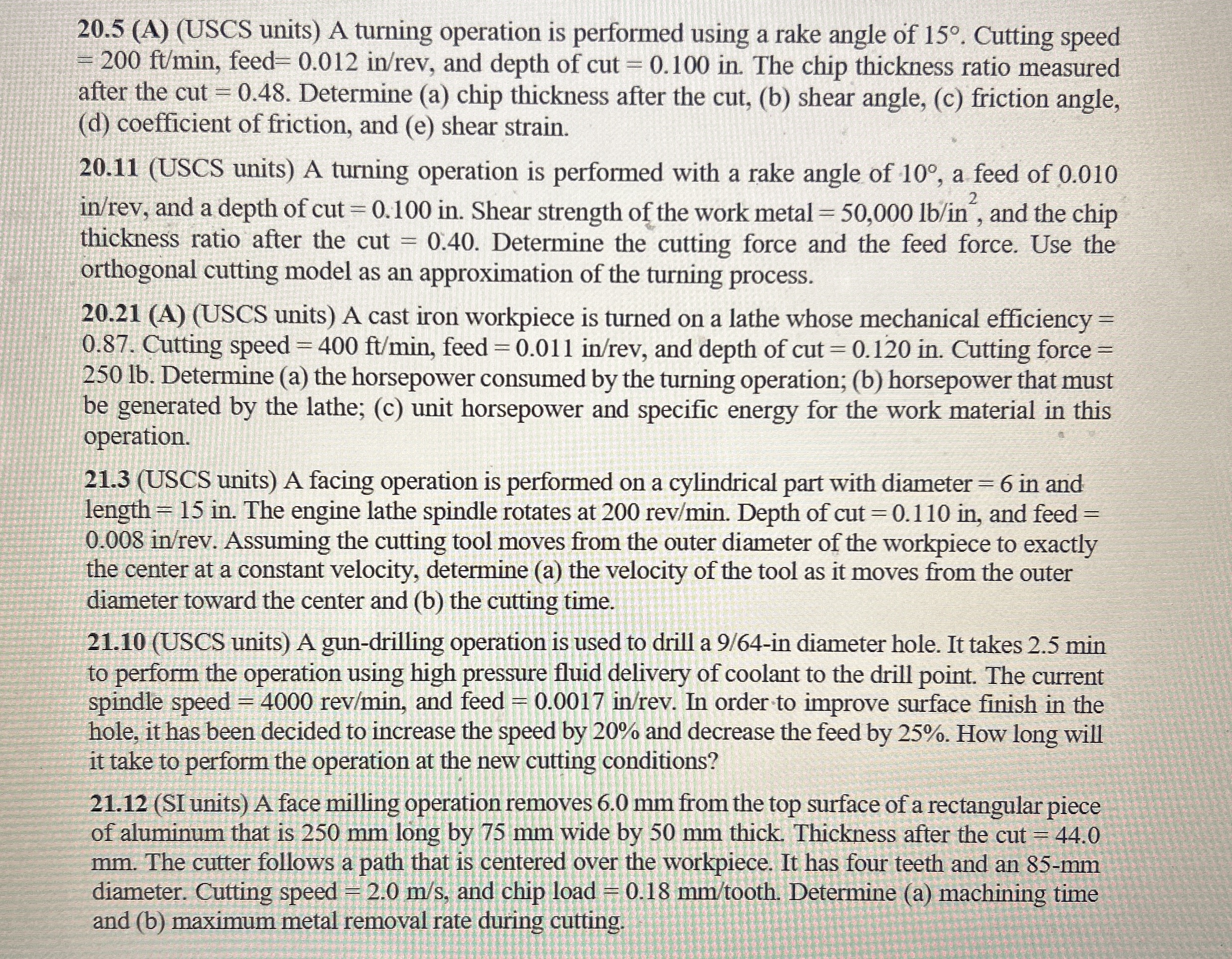

Question: 2 0 . 5 ( A ) ( USCS units ) A turning operation is performed using a rake angle of 1 5 . Cutting

AUSCS units A turning operation is performed using a rake angle of Cutting speed

feed and depth of cut The chip thickness ratio measured

after the cut Determine a chip thickness after the cut, b shear angle, c friction angle,

d coefficient of friction, and e shear strain.

USCS units A turning operation is performed with a rake angle of a feed of

and a depth of cut Shear strength of the work metal and the chip

thickness ratio after the cut Determine the cutting force and the feed force. Use the

orthogonal cutting model as an approximation of the turning process.

AUSCS units A cast iron workpiece is turned on a lathe whose mechanical efficiency

Cutting speed feed and depth of cut Cutting force

lb Determine a the horsepower consumed by the turning operation; b horsepower that must

be generated by the lathe; c unit horsepower and specific energy for the work material in this

operation.

USCS units A facing operation is performed on a cylindrical part with diameter in and

length The engine lathe spindle rotates at Depth of cut and feed

Assuming the cutting tool moves from the outer diameter of the workpiece to exactly

the center at a constant velocity, determine a the velocity of the tool as it moves from the outer

diameter toward the center and b the cutting time.

USCS units A gundrilling operation is used to drill a in diameter hole. It takes min

to perform the operation using high pressure fluid delivery of coolant to the drill point. The current

spindle speed and feed In order to improve surface finish in the

hole, it has been decided to increase the speed by and decrease the feed by How long will

it take to perform the operation at the new cutting conditions?

SI units A face milling operation removes mm from the top surface of a rectangular piece

of aluminum that is mm long by mm wide by mm thick. Thickness after the cut

mm The cutter follows a path that is centered over the workpiece. It has four teeth and an

diameter. Cutting speed and chip load tooth. Determine a machining time

and b maximum metal removal rate during cutting.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock