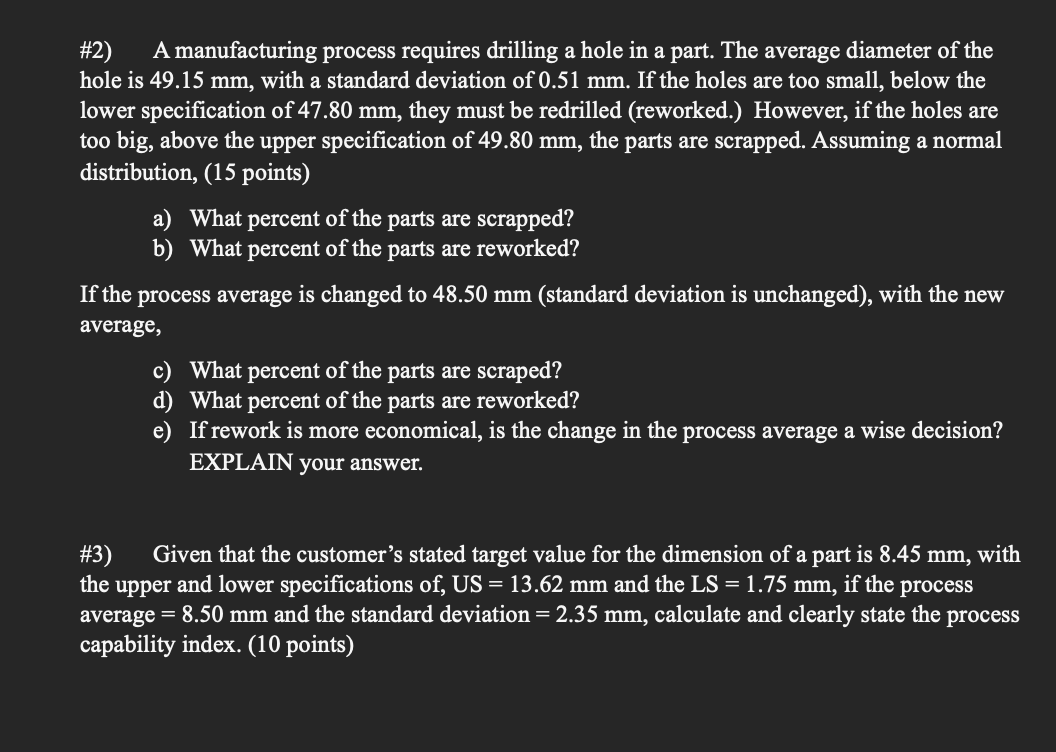

Question: # 2 ) A manufacturing process requires drilling a hole in a part. The average diameter of the hole is 4 9 . 1 5

# A manufacturing process requires drilling a hole in a part. The average diameter of the

hole is with a standard deviation of If the holes are too small, below the

lower specification of they must be redrilled reworked However, if the holes are

too big, above the upper specification of the parts are scrapped. Assuming a normal

distribution, points

a What percent of the parts are scrapped?

b What percent of the parts are reworked?

If the process average is changed to standard deviation is unchanged with the new

average,

c What percent of the parts are scraped?

d What percent of the parts are reworked?

e If rework is more economical, is the change in the process average a wise decision?

EXPLAIN your answer.

# Given that the customer's stated target value for the dimension of a part is with

the upper and lower specifications of US and the if the process

average and the standard deviation calculate and clearly state the process

capability index. points

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock