Question: 2. Aluminum electrical conductor wire is made by multi-step drawing. The starting rod of 9.5 mm diameter is reduced to 2.0 mm diameter by

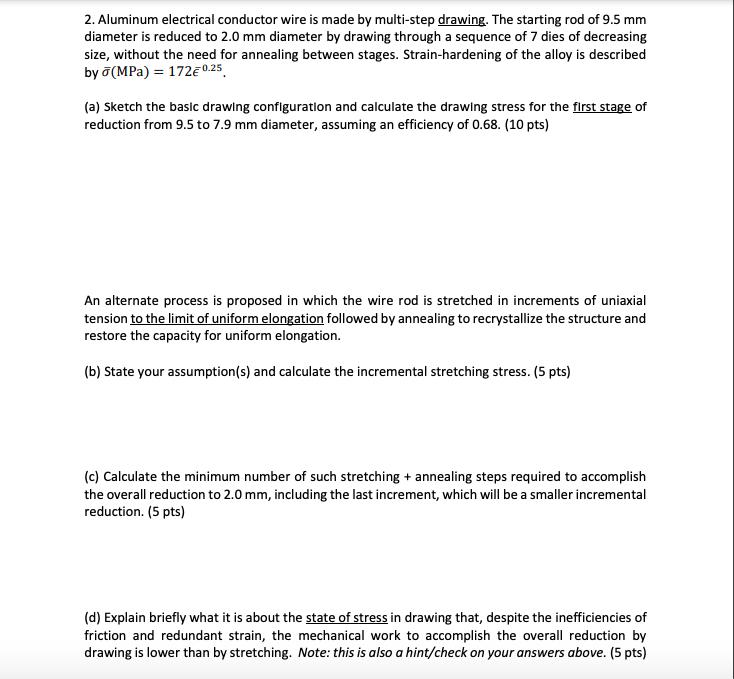

2. Aluminum electrical conductor wire is made by multi-step drawing. The starting rod of 9.5 mm diameter is reduced to 2.0 mm diameter by drawing through a sequence of 7 dies of decreasing size, without the need for annealing between stages. Strain-hardening of the alloy is described by (MPa) = 172 0.25 (a) Sketch the basic drawing configuration and calculate the drawing stress for the first stage of reduction from 9.5 to 7.9 mm diameter, assuming an efficiency of 0.68. (10 pts) An alternate process is proposed in which the wire rod is stretched in increments of uniaxial tension to the limit of uniform elongation followed by annealing to recrystallize the structure and restore the capacity for uniform elongation. (b) State your assumption(s) and calculate the incremental stretching stress. (5 pts) (c) Calculate the minimum number of such stretching + annealing steps required to accomplish the overall reduction to 2.0 mm, including the last increment, which will be a smaller incremental reduction. (5 pts) (d) Explain briefly what it is about the state of stress in drawing that, despite the inefficiencies of friction and redundant strain, the mechanical work to accomplish the overall reduction by drawing is lower than by stretching. Note: this is also a hint/check on your answers above. (5 pts)

Step by Step Solution

There are 3 Steps involved in it

Based on the information provided lets address each part of the question step by step a To calculate the drawing stress for the first stage of reduction from 95 mm to 79 mm diameter we can use the for... View full answer

Get step-by-step solutions from verified subject matter experts