Question: 2. Use the least squares method to develop the estimated regression equation.3. Predict the number of defective parts found for a line speed of 35

2. Use the least squares method to develop the estimated regression equation.3. Predict the number of defective parts found for a line speed of 35 feet per minute.

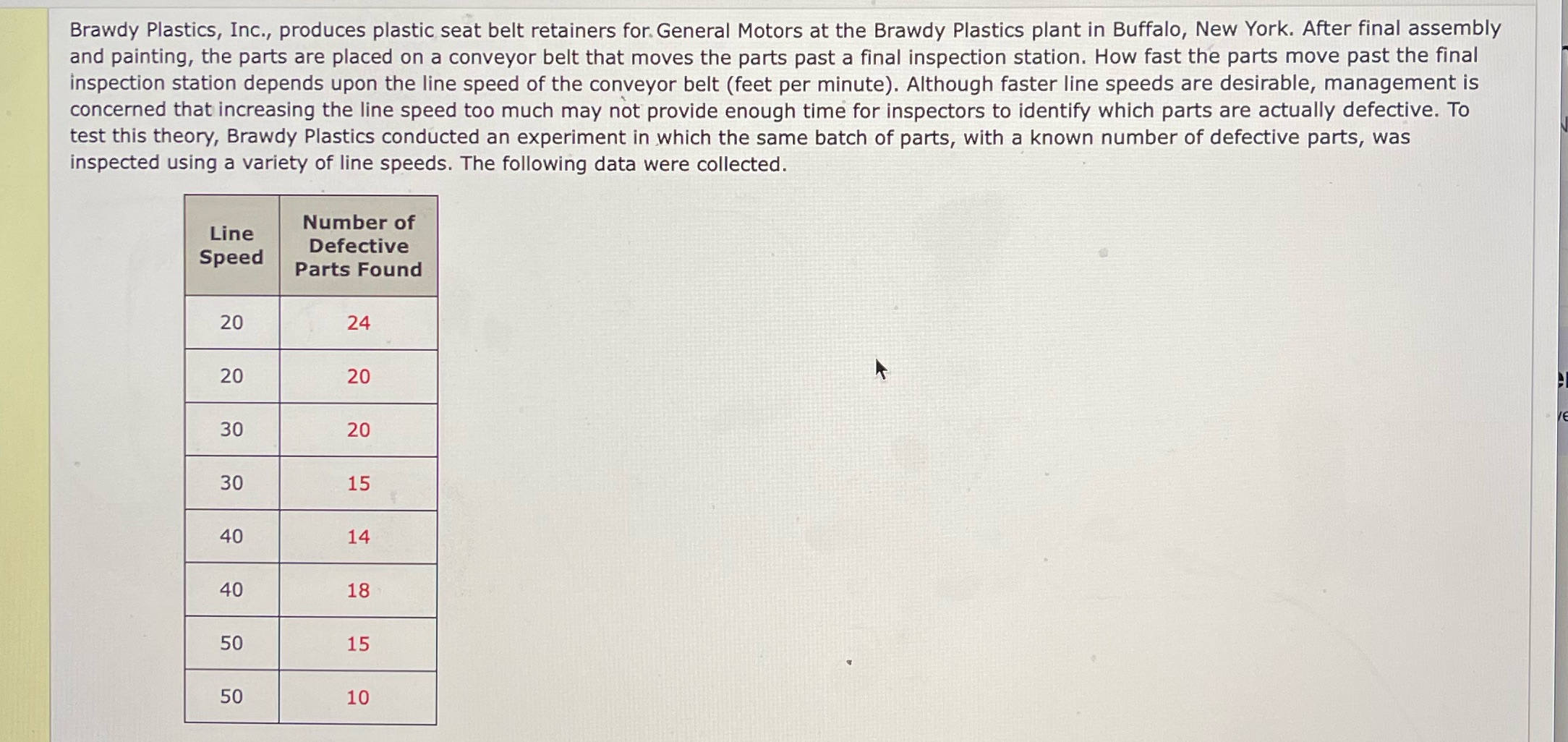

Brawdy Plastics, Inc., produces plastic seat belt retainers for. General Motors at the Brawdy Plastics plant in Buffalo, New York. After final assembly and painting, the parts are placed on a conveyor belt that moves the parts past a final inspection station. How fast the parts move past the final inspection station depends upon the line speed of the conveyor belt (feet per minute). Although faster line speeds are desirable, management is concerned that increasing the line speed too much may not provide enough time for inspectors to identify which parts are actually defective. To test this theory, Brawdy Plastics conducted an experiment in which the same batch of parts, with a known number of defective parts, was inspected using a variety of line speeds. The following data were collected. Line Number of Speed Defective Parts Found 20 24 20 20 30 20 30 15 40 14 40 18 50 15 50 10

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts