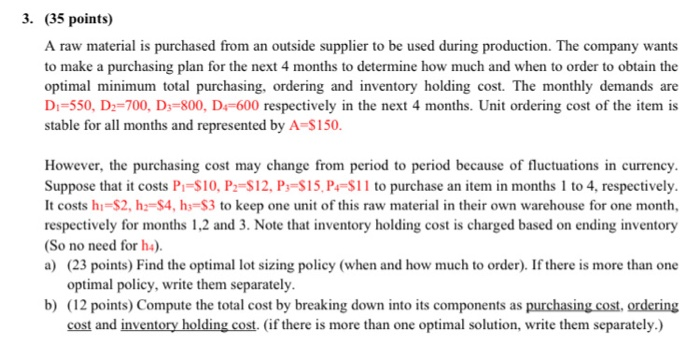

3. (35 points) A raw material is purchased from an outside supplier to be used during production. The company wants to make a purchasing plan for the next 4 months to determine how much and when to order to obtain the optimal minimum total purchasing, ordering and inventory holding cost. The monthly demands are Di=550, D2=700, D3=800, Da=600 respectively in the next 4 months. Unit ordering cost of the item is stable for all months and represented by A-S150. However, the purchasing cost may change from period to period because of fluctuations in currency. Suppose that it costs Ps=$10, P=$12, P;=$15, Pa=$11 to purchase an item in months 1 to 4, respectively. It costs hi=92, h=94, h5=3 to keep one unit of this raw material in their own warehouse for one month, respectively for months 1,2 and 3. Note that inventory holding cost is charged based on ending inventory (So no need for hu). a) (23 points) Find the optimal lot sizing policy (when and how much to order). If there is more than one optimal policy, write them separately. b) (12 points) Compute the total cost by breaking down into its components as purchasing cost, ordering cost and inventory holding cost. (if there is more than one optimal solution, write them separately.) 3. (35 points) A raw material is purchased from an outside supplier to be used during production. The company wants to make a purchasing plan for the next 4 months to determine how much and when to order to obtain the optimal minimum total purchasing, ordering and inventory holding cost. The monthly demands are Di=550, D2=700, D3=800, Da=600 respectively in the next 4 months. Unit ordering cost of the item is stable for all months and represented by A-S150. However, the purchasing cost may change from period to period because of fluctuations in currency. Suppose that it costs Ps=$10, P=$12, P;=$15, Pa=$11 to purchase an item in months 1 to 4, respectively. It costs hi=92, h=94, h5=3 to keep one unit of this raw material in their own warehouse for one month, respectively for months 1,2 and 3. Note that inventory holding cost is charged based on ending inventory (So no need for hu). a) (23 points) Find the optimal lot sizing policy (when and how much to order). If there is more than one optimal policy, write them separately. b) (12 points) Compute the total cost by breaking down into its components as purchasing cost, ordering cost and inventory holding cost. (if there is more than one optimal solution, write them separately.)