Question: 3 Problem 1 ( 2 0 pts ) : A manufacturing company has received an order to machine 1 0 0 0 parts. For quality

Problem pts:

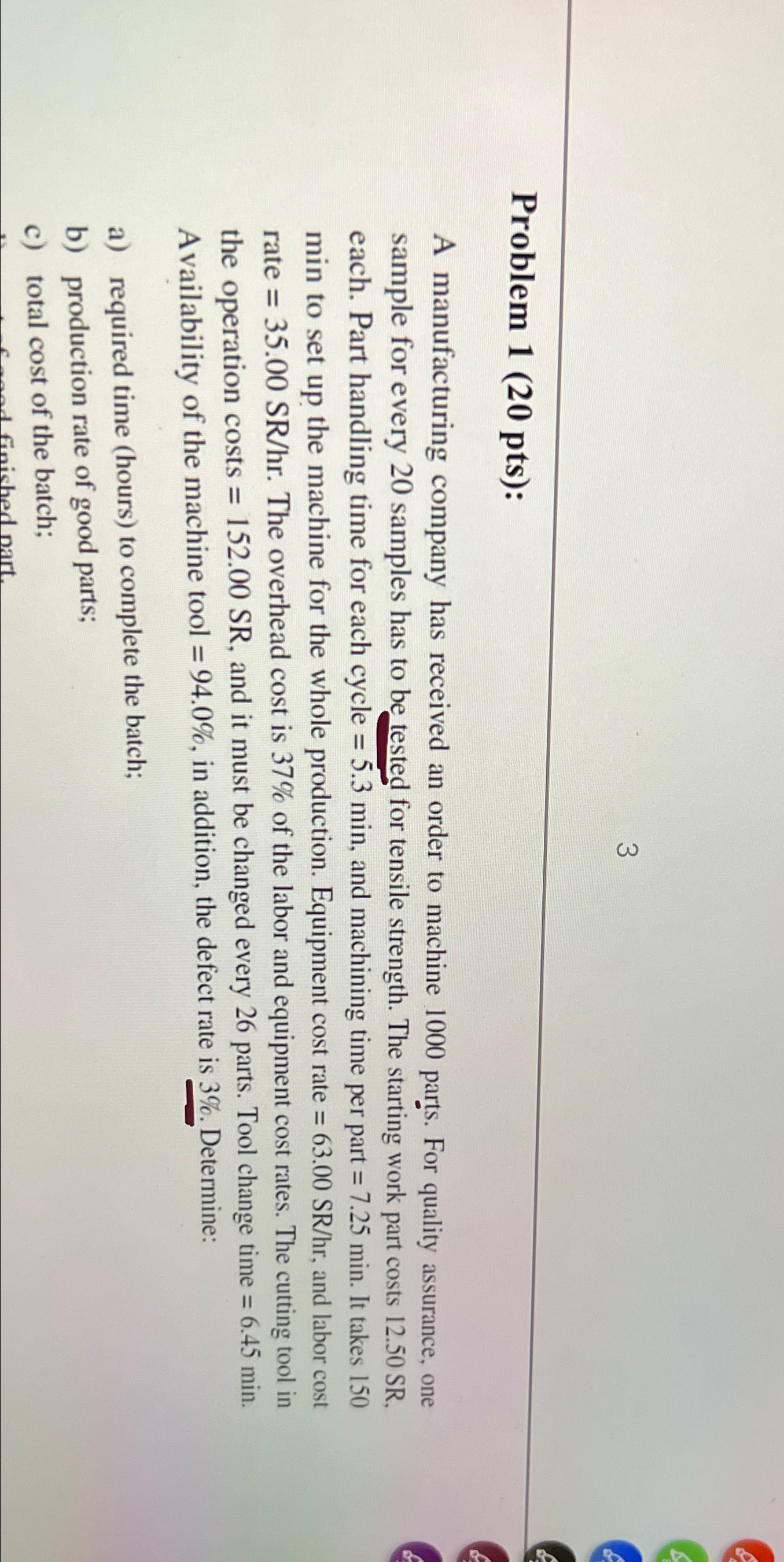

A manufacturing company has received an order to machine parts. For quality assurance, one sample for every samples has to be tested for tensile strength. The starting work part costs SR each. Part handling time for each cycle min, and machining time per part min. It takes min to set up the machine for the whole production. Equipment cost rate and labor cost rate The overhead cost is of the labor and equipment cost rates. The cutting tool in the operation costs and it must be changed every parts. Tool change time min. Availability of the machine tool in addition, the defect rate is Determine:

a required time hours to complete the batch;

b production rate of good parts;

c total cost of the batch;

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock