Question: please help Delta Plastic B I forgot to attach. This is a two part case study these are from case study Delta Plastics A and

please help Delta Plastic B

I forgot to attach. This is a two part case study these are from case study Delta Plastics A and you have the Delta Plastics B please help

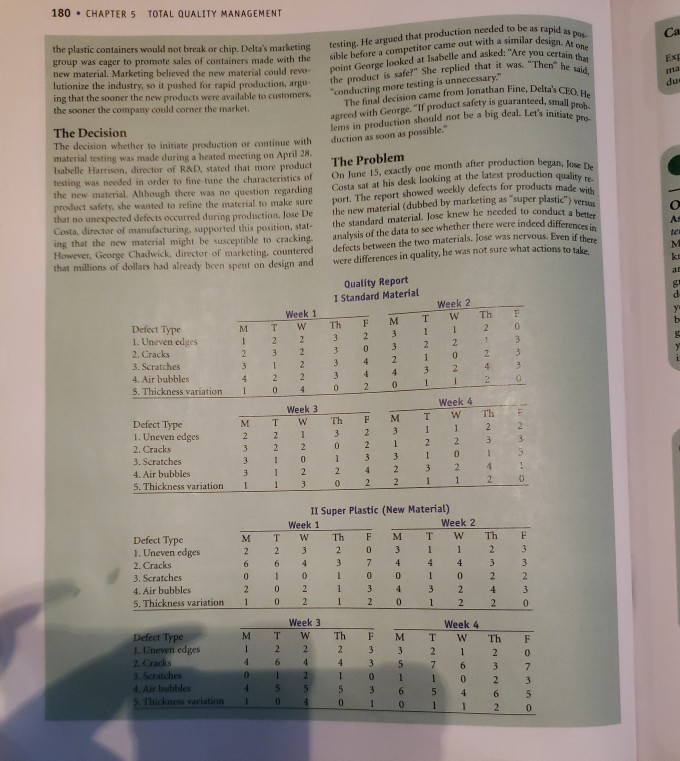

Jose had been opposed to starting production until R&D had fully completed testing and refining the new material. However, the CEO of Delta had ordered production despite objections from manufacturing and R&D. Jose carefully looked at the re- port in front of him and prepared to analyze the results. CASE: Delta Plastics, Inc. (B) Jose De Costa, director of manufacturing at Delta Plastics, sat at his desk looking at the latest production quality report, showing the number and type of product defects per week (see the qual- ity report in Delta Plastics, Inc. Case A, Chapter 5). He was faced with the task of evaluating production quality for products made with two different materials. One of the materials was new and called "super plastic" due to its ability to sustain large tem- perature changes. The other material was the standard plastic that had been successfully used by Delta for many years. The company had started producing products with the new super plastic material only a month earlier. Jose suspected that the new material could result in more defects during the pro- duction process than the standard material they had been using. Case Questions 1. Prepare a 3-sigma control chart for both production processes, using the new and standard material (use the quality report in Delta Plastics, Inc. Case A. Chapter 5). Are both processes in control? What can you conclude? 2. Are both materials equally subject to the defects? 3. Given your findings, what advice would you give Jose? CASE: Delta Plastics, Inc. (A) Company Background Delta Plastics, Inc. specialized in the design and manufacture of plastic containers, primarily for kitchen and household use. Its products were sold through merchandise retailers and were rec- ognized for high quality. Delta also had an active R&D group that was continuously working to develop new plastic materials and new product designs. Delta was a recognized industry leader and was aggressively looking to increase brand recognition and market share. Delta's R&D group had recently developed a new plastic ma- terial that tolerates rapid changes in temperature, from heating to deep cooling. This material could be used to make containers for kitchen use that could immediately be moved from the oven to the refrigerator. Unlike glass containers with this capability, testing. He argued that production needed to be as rapid as pos sible before a competitor came out with a similar design. At one point George looked at Isabelle and asked: "Are you certain than the product is safe? She replied that it was. "Then" he said, The final decision came from Jonathan Fine, Delta's CF.C. He agreed with George. "If product safety is guaranteed, small prob On June 15, exactly one month after production began, Jose De Costa sat at his desk looking at the latest production quality re- port. The report showed weekly defects for products made with the new material (dubbed by marketing as "super plastic") vers the standard material. Jose knew he needed to conduct a better analysis of the data to see whether there were indeed differences in lems in production should not be a big deal. Let's initiate defects between the two materials. Jose was nervous. Even if the 180 CHAPTER 5 TOTAL QUALITY MANAGEMENT Exp dus conducting more testing is unnecessary." pro duction as soon as possible." the plastic containers would not break or chip, Delta's marketing group was eager to promote sales of containers made with the new material. Marketing believed the new material could revo lutionize the industry, so it pushed for rapid production, argu- ing that the sooner the new products were available to customers. the sooner the company could corner the market. The Decision The decision whether to initiate production or continue with material testing was made during a heated meeting on April 28 Isabelle Harrison, director of R&D, stated that more product testing was needed in order to fine-tune the characteristics of the new material. Although there was no question regarding product safety, she wanted to refine the material to make sure that no unexpected defects occurred during production. Jose De director of manufacturing, supported this position, stat- ing that the new material might be susceptible to cracking However, George Chadwick, director of marketing, countered that millions of dollars had already been spent on design and The Problem o AS te M ku were differences in quality, he was not sure what actions to take Quality Report 1 Standard Material d y b M 3 Defect Type 1. Uneven edges 2. Cracks 3. Scratches 4. Air bubbles 5. Thickness variation M 1 2 3 4 1 T 2 3 1 2 0 Week 1 W 2 2 2 2 4 Th 3 3 3 3 F 2 0 4 4 2 T 1 2 1 3 1 Week 2 w Th 1 2 2 1 0 2 2 4 1 2 F 0 3 3 3 0 2 4 0 0 Defect Type 1. Uneven 2. Cracks 3. Scratches 4. Air bubbles 5. Thickness variation M 2 3 3 3 1 T 2 2 1 1 1 Week 3 w 1 2 0 2 3 Th 3 0 1 2 0 F 2 2 3 4 2 3 1 3 2 2 T 1 2 1 3 1 Week 4 w 1 2 0 2 1 Th 2 3 1 4 2 2 3 3 1 0 Defect Type 1. Uneven edges 2. Cracks 3. Scratches 4. Air bubbles 5. Thickness variation M 2 6 0 2 1 T 2 6 1 0 0 II Super Plastic (New Material) Week 1 Week 2 w Th F M T w 3 2 0 3 1 1 4 3 7 4 4 4 0 1 0 0 1 0 2 1 3 4 3 2 2 1 2 0 1 2 Th 2 3 2 4 2 F 3 3 2 3 0 2 M 1 F 3 3 M 3 Defect Type 1. Uneven edges 2 Cracks 3. Scratches 4. Air bubble 5. Thickness variation 4 0 4 Week 3 w 2 4 2 5 4 T 2 6 1 5 0 Th 2 4 1 5 0 5 1 6 0 T 2 7 1 5 1 Week 4 w Th 1 2 6 3 0 2 4 6 1 2 F 0 7 3 5 0 1 3 1 INTERNET CHALLENGE SNYDER BAKERIES . 181 Case Questions 1. Identify the different costs of quality described in the case. Explain the trade-offs between the costs of quality that Delta made in its decision. Was George Chadwick correct that con- ducting more tests was unnecessary? 2. Use one of the quality tools described in the chapter to analyze the defects in the case. How do the quality dimensions differ between the two materials? Are there more defects associ- ated with the super plastic versus the standard material? 3. Given your findings, what should lose doStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts