Question: 312 PART 2 DESIGNING OPERATIONS CASE STUDIES Cecil Rice Export, Alexandria, Egypt Cal Rie Export operates a facility in Alexandria, Egypt where hulk white rice

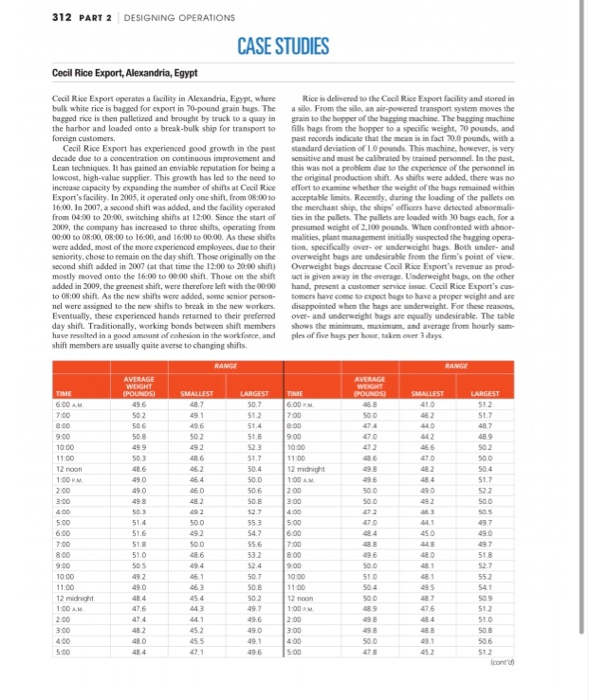

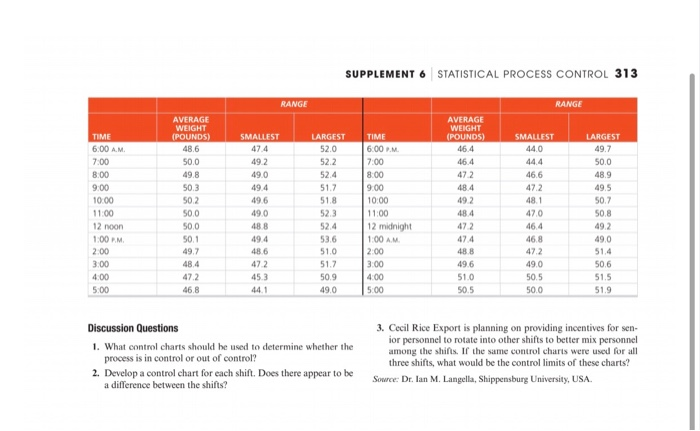

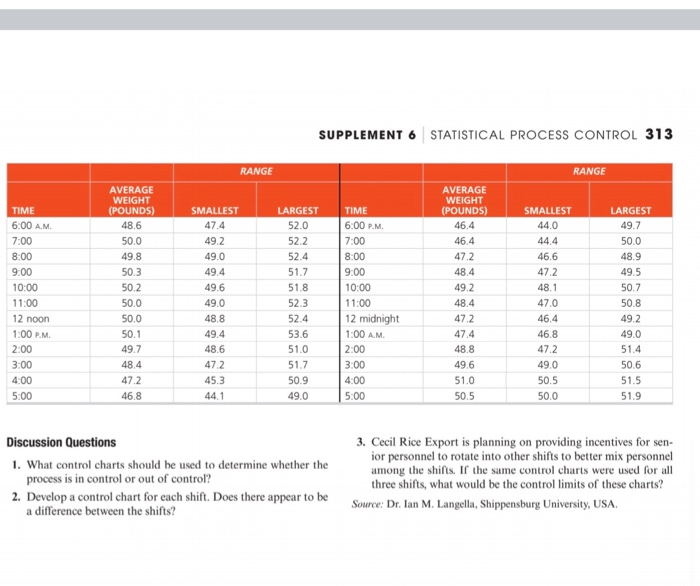

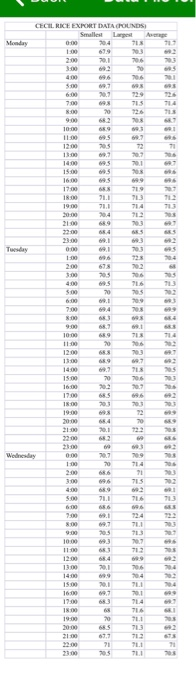

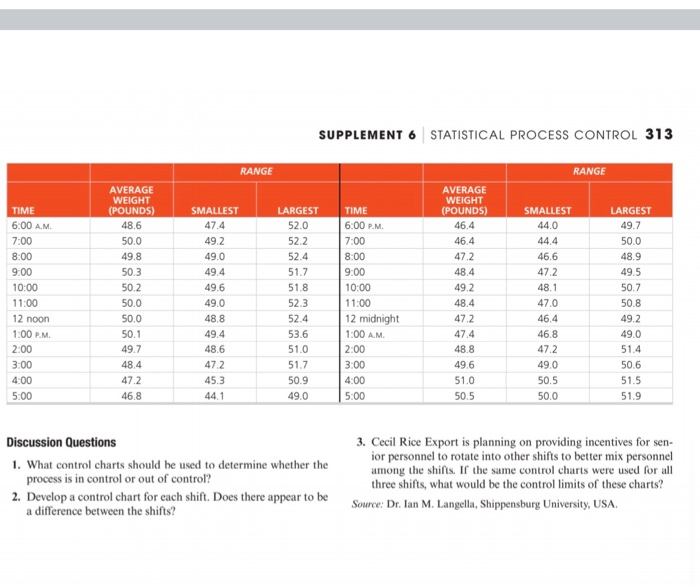

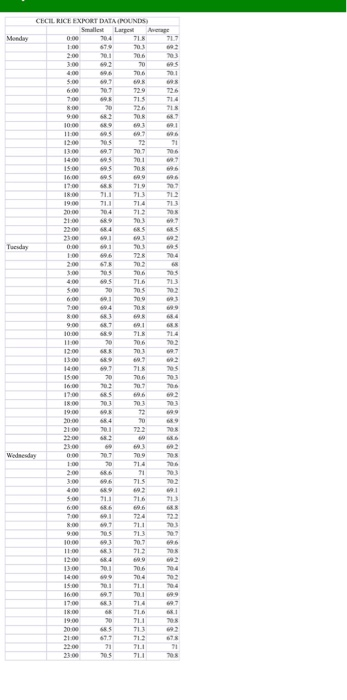

312 PART 2 DESIGNING OPERATIONS CASE STUDIES Cecil Rice Export, Alexandria, Egypt Cal Rie Export operates a facility in Alexandria, Egypt where hulk white rice is hard for sportin poudaines The hard rice is the police and brought by track to a quay is the harbor and loaded to break-bulk ship for transport to for customer Cocil Rice Export has experienced poedgrowth in the past decade due to a concentration contus improvement and Le techniques. It has gained a covale reputation for being a lowcost, high-value supplier. This growth has led to the need to in c apacity by expanding the number of shifts at Cecil Rice Export's facility. In 2005, it operated only one shift from 08:00 16.00. In 2007. a second shift was added, and the facility operated from 0400 20:00, wwitching shifts at 12:00 Since the start of 2009, the company has increased to three shifts, operating from 0-00 O:00 O:00 to 16.00, and 16.00 to 0000. As the shifts were added most of the more experienced employees due to their seniority. chose to remain on the day shift The originally on the second shift added in 2007 at that time the 12:00 20:00 shift) mostly moved onto the 16:00 to 0000 shift Thou on the hitt added in 2009, the greenest shift, were therefore left with the 10 08:00 shift. As the new shifts were added, w e wnior pero nel were assigned to the new shifts to break in the new workers Eventually, these experienced and returned to their preferred day shift Traditionally, working bonds between shift members have resulted in a good amount of cohesion in the work and shift members are usually quite avere to chanping shifts Ricei ddod to the Cool Rice Export facility and stored in as From the powered transport moves the rain to the hear of the h igh . The machine fills bags from the hopper to a specific weight, 70 pounds, and pas records indicate that the man is in fact 700 pounds with a standard deviation of pounds. This machine, however, is very sensitive and must be calibrated by trained personnel. In the past this was not a prom o te the experience of the personnel in the original production that were added there was no clot to whether tha t of the remained within acceptable limits Recent during the loading of the pallets on the merchant ship the cho ices have detected abermal ties in the pets. The puts an d with the cach, fora promed wet of 2.100 pounds When confronted with aber malities, plant management initially suspected the bagging opera tion specifically ove r weight bags Both under and overweight has an und e r the firm's point of view Overweight as decrease Cecil Rise Export's revenue as prod isiv hand, present a customer service Cecil Rice Expert's tomers have come to expect to have a proper weight and are disappointed when the han derweiht. For these son over and underweh bapare qually undesirable. The table shows the minimum, maximum, and average from hourly sam ples of the haper how taken over days RANGE AVERAGE WEIGHT (POUNDS SMALLEST LARGEST POUNDS SMALLEST LARGEST 700 0.00 506 47.4 508 518 1000 10:00 11.00 12 mocht 50.4 504 16+ 196 12 noon 100 200 3.00 200 506 50 B 02 500 553 532 518 5.00 6.00 7.00 8.00 900 1000 1100 12 m 10 AM 4 492 510 504 4 3 04 252 SUPPLEMENT 6 STATISTICAL PROCESS CONTROL 313 RANGE RANGE AVERAGE AVERAGE TIME TIME (POUNDS) LARGEST (POUNDS) 48.6 50.0 6 00 AM 7:00 46.4 SMALLEST 44.0 44.4 192 46.4 472 8.00 49.8 49.0 46.6 LARGEST 52.0 52.2 52.4 51.7 51.8 52.3 52.4 50.3 494 484 422 502 492 49.6 49.0 48.1 47.0 484 9.00 10:00 11:00 12 noon 1:00 PM 2:00 3.00 ABS 600 PM 7.00 8:00 9.00 10.00 11.00 12 midnight 1:00 AM 2:00 3:00 400 5:00 472 46.4 46.8 50.0 48.9 49.5 50.7 50.8 49.2 49.0 51.4 506 51.5 51.9 50.0 50.0 50.1 49.7 48.4 47.2 46.8 494 536 474 488 48.6 472 49.6 472 453 51.0 517 50.9 49.0 510 4.00 5.00 49.0 50.5 50.0 441 50.5 Discussion Questions 1. What control charts should be used to determine whether the process is in control or out of control? 2. Develop a control chart for each shift. Does there appear to be a difference between the shifts? 3. Cecil Rice Export is planning on providing incentives for sen- ior personnel to rotate into other shifts to better mix personnel among the shifts. If the same control charts were used for all three shifts, what would be the control limits of these charts? Source: Dr. lan M. Langella, Shippensburg University, USA 12:38