Question: ( 4 0 ) Consider the aluminum extrusion process, which involves heating a billet to 5 0 0 C and then pressing it through a

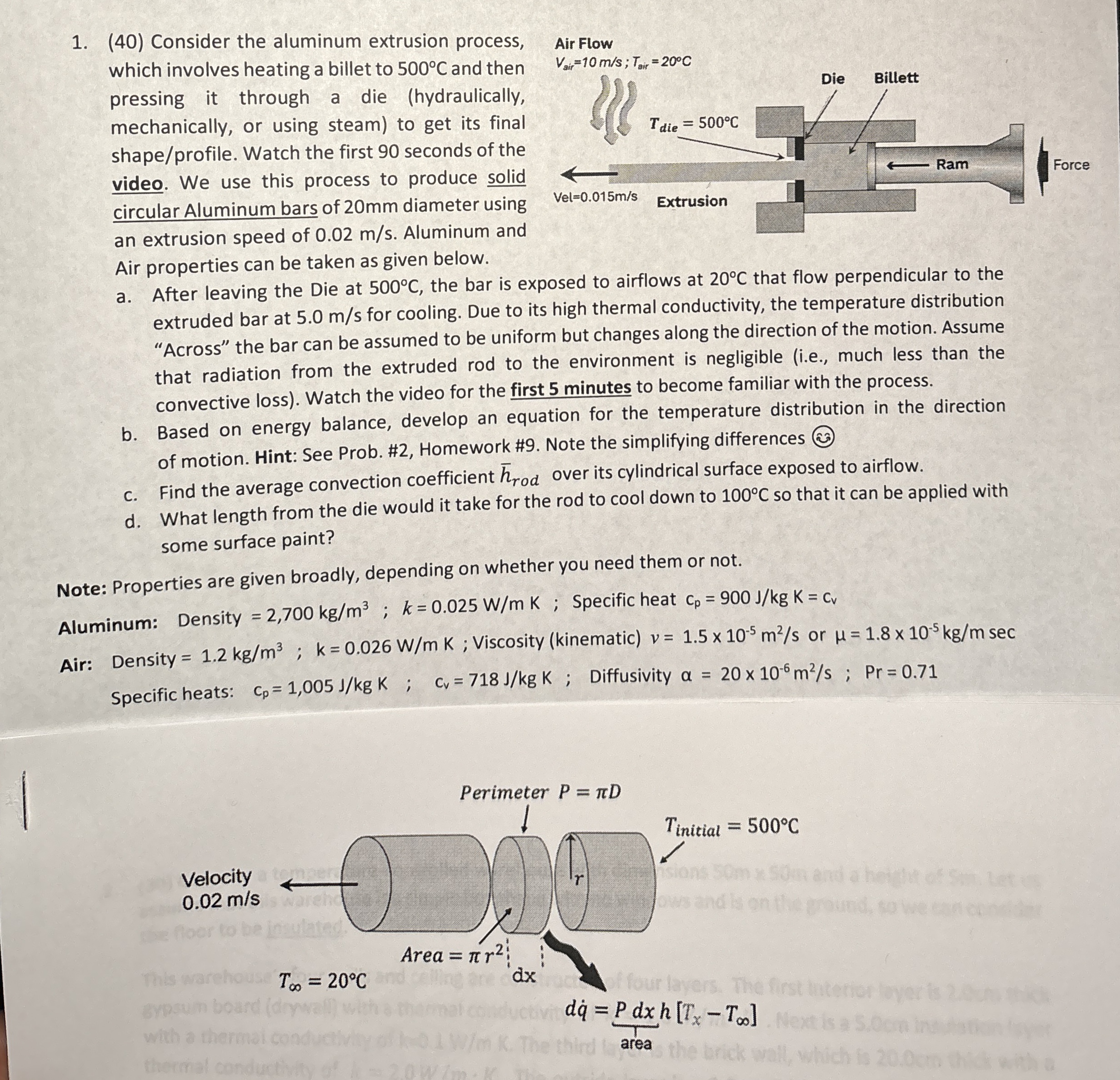

Consider the aluminum extrusion process,

which involves heating a billet to and then

pressing it through a die hydraulically

mechanically, or using steam to get its final

shapeprofile Watch the first seconds of the

video. We use this process to produce solid

circular Aluminum bars of mm diameter using

an extrusion speed of Aluminum and

Air properties can be taken as given below.

a After leaving the Die at the bar is exposed to airflows at that flow perpendicular to the

extruded bar at for cooling. Due to its high thermal conductivity, the temperature distribution

"Across" the bar can be assumed to be uniform but changes along the direction of the motion. Assume

that radiation from the extruded rod to the environment is negligible ie much less than the

convective loss Watch the video for the first minutes to become familiar with the process.

b Based on energy balance, develop an equation for the temperature distribution in the direction

of motion. Hint: See Prob. # Homework # Note the simplifying differences

c Find the average convection coefficient over its cylindrical surface exposed to airflow.

d What length from the die would it take for the rod to cool down to so that it can be applied with

some surface paint?

Note: Properties are given broadly, depending on whether you need them or not.

Aluminum: Density ;; Specific heat

Air: Density ;; Viscosity kinematic or

Specific heats: ;; Diffusivity ; Consider the aluminum extrusion process,

which involves heating a billet to and then

pressing it through a die hydraulically

mechanically, or using steam to get its final

shapeprofile Watch the first seconds of the

video. We use this process to produce solid

circular Aluminum bars of mm diameter using

an extrusion speed of Aluminum and

Air properties can be taken as given below.

a After leaving the Die at the bar is exposed to airflows at that flow perpendicular to the

extruded bar at for cooling. Due to its high thermal conductivity, the temperature distribution

"Across" the bar can be assumed to be uniform but changes along the direction of the motion. Assume

that radiation from the extruded rod to the environment is negligible ie much less than the

convective loss Watch the video for the first minutes to become familiar with the process.

b Based on energy balance, develop an equation for the temperature distribution in the direction

of motion. Hint: See Prob. # Homework # Note the simplifying differences

c Find the average convection coefficient over its cylindrical surface exposed to airflow.

d What length from the die would it take for the rod to cool down to so that it can be applied with

some surface paint?

Note: Properties are given broadly, depending on whether you need them or not.

Aluminum: Density ;; Specific heat

Air: Density ;; Viscosity kinematic or

Specific heats: ;; Diffusivity ;

Consider the aluminum extrusion process,

which involves heating a billet to and then

pressing it through a die hydraulically

mechanically, or using steam to get its final

shapeprofile Watch the first seconds of the

video. We use this process to produce solid

circular Aluminum bars of mm diameter using

an extrusion speed of Aluminum and

Air properties can be taken as given below.

a After leaving the Die at the bar is exposed to airflows at

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock