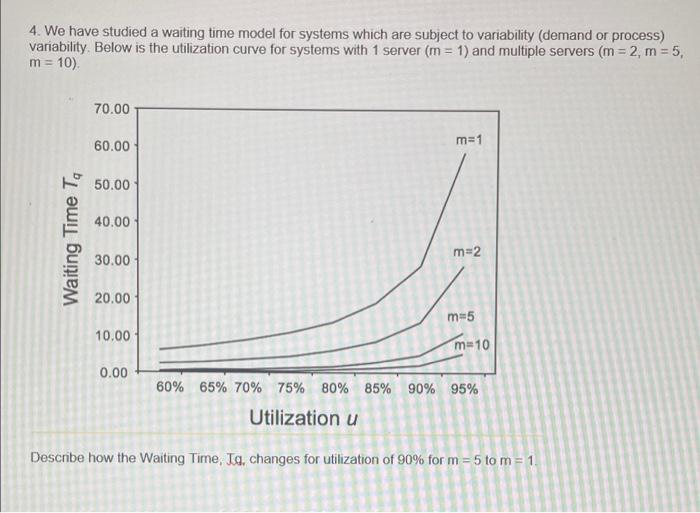

Question: 4. We have studied a waiting time model for systems which are subject to variability (demand or process) variability. Below is the utilization curve for

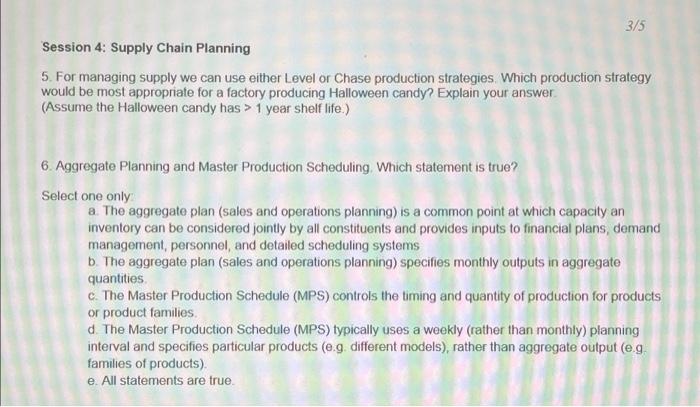

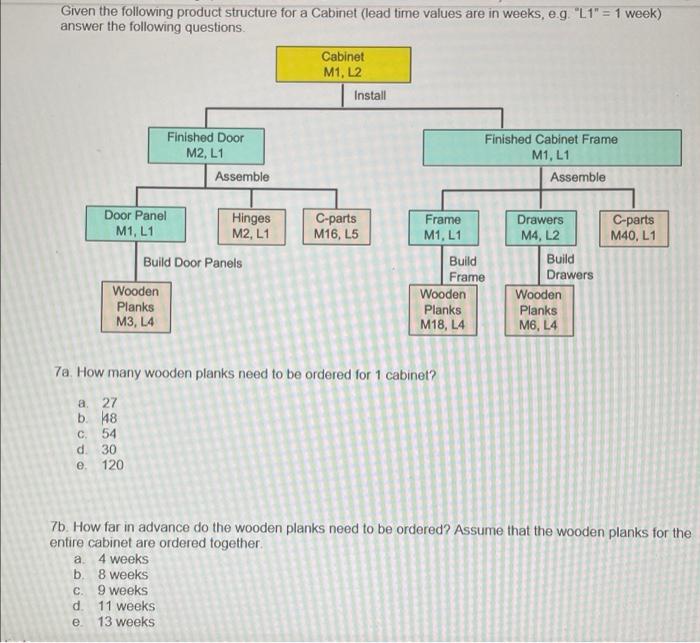

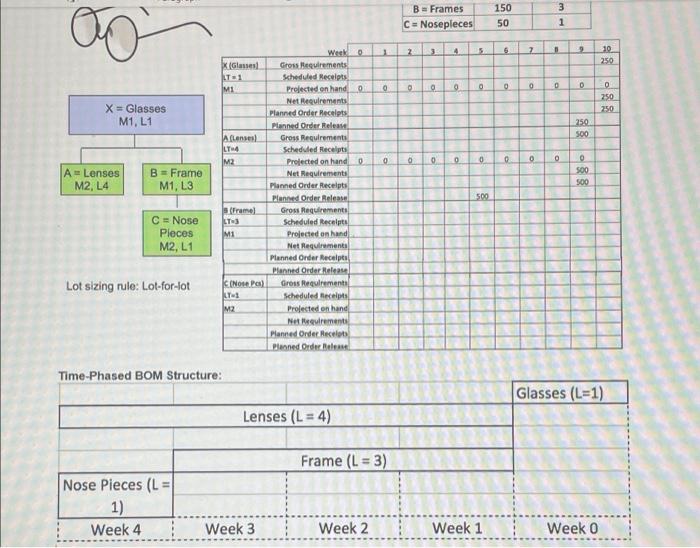

4. We have studied a waiting time model for systems which are subject to variability (demand or process) variability. Below is the utilization curve for systems with 1 server (m = 1) and multiple servers (m=2, m=5, m= 10) 70.00 60.00 m=1 50.00 40.00 Waiting Time To m=2 30.00 20.00 m=5 10.00 m=10 0.00 60% 65% 70% 75% 80% 85% 90% 95% Utilization u Describe how the Waiting Time, Tg, changes for utilization of 90% form = 5 to m= 1 3/5 Session 4: Supply Chain Planning 5. For managing supply we can use either Level or Chase production strategies. Which production strategy would be most appropriate for a factory producing Halloween candy? Explain your answer (Assume the Halloween candy has > 1 year shelf life.) 6. Aggregate Planning and Master Production Scheduling Which statement is true? Select one only a. The aggregate plan (sales and operations planning) is a common point at which capacity an inventory can be considered jointly by all constituents and provides inputs to financial plans, demand management, personnel, and detailed scheduling systems b. The aggregate plan (sales and operations planning) specifies monthly outputs in aggregate quantities c. The Master Production Schedule (MPS) controls the timing and quantity of production for products or product families d. The Master Production Schedule (MPS) typically uses a weekly (rather than monthly) planning interval and specifies particular products (0.9. different models), rather than aggregate output (e.g families of products) e. All statements are true. Given the following product structure for a Cabinet (lead time values are in weeks, eg. "L1" = 1 week) answer the following questions Cabinet M1, L2 Install Finished Door M2, L1 Assemble Finished Cabinet Frame M1, L1 Assemble Door Panel M1, L1 Hinges M2, L1 C-parts M16, L5 Frame M1, L1 C-parts M40, L1 Build Door Panels Wooden Planks M3, L4 Build Frame Wooden Planks M18, L Drawers M4, L2 Build Drawers Wooden Planks M6, L4 7a. How many wooden planks need to be ordered for 1 cabinet? a 27 b. 148 C. 54 30 120 d e 76. How far in advance do the wooden planks need to be ordered? Assume that the wooden planks for the entire cabinet are ordered together a 4 weeks b. 8 weeks c. 9 weeks 11 weeks 13 weeks d e B = Frames C = Nosepleces 150 50 3 1 ao 1 2 3 4 6 7 9 10 250 K(Glasses LT=1 MI 0 0 0 0 0 0 D O 0 0 250 750 X = Glasses M1, L1 250 500 Allenses LT24 M2 0 0 0 0 0 0 0 0 8 A Lenses M2, L4 B = Frame M1, L3 SOO 500 Week Gross Requirements Scheduled Receipts Projected on hand Net Requirements Planned Order Receipts Planned Order Release Gross Requirements Scheduled Receipts Projected on hand Net Requirements Planned Order Receipts Planned Order Release Gross Requirements Scheduled Receipts Projected on hand Net Requirements Planned Order Recepti Planned Order Release Gross Requirements Scheduled Receipts Projected on hand Nelairements Planned Order Hecelets Planned Order 500 C = Nose Pleces M2, L1 (Framel LT-3 MI Lot sizing rule: Lot-for-lot Nose. Po LT MZ Time-Phased BOM Structure: Glasses (L=1) Lenses (L = 4) Frame (L = 3) Nose Pieces (L = 1) Week 4 Week 3 Week 2 Week 1 Week 0