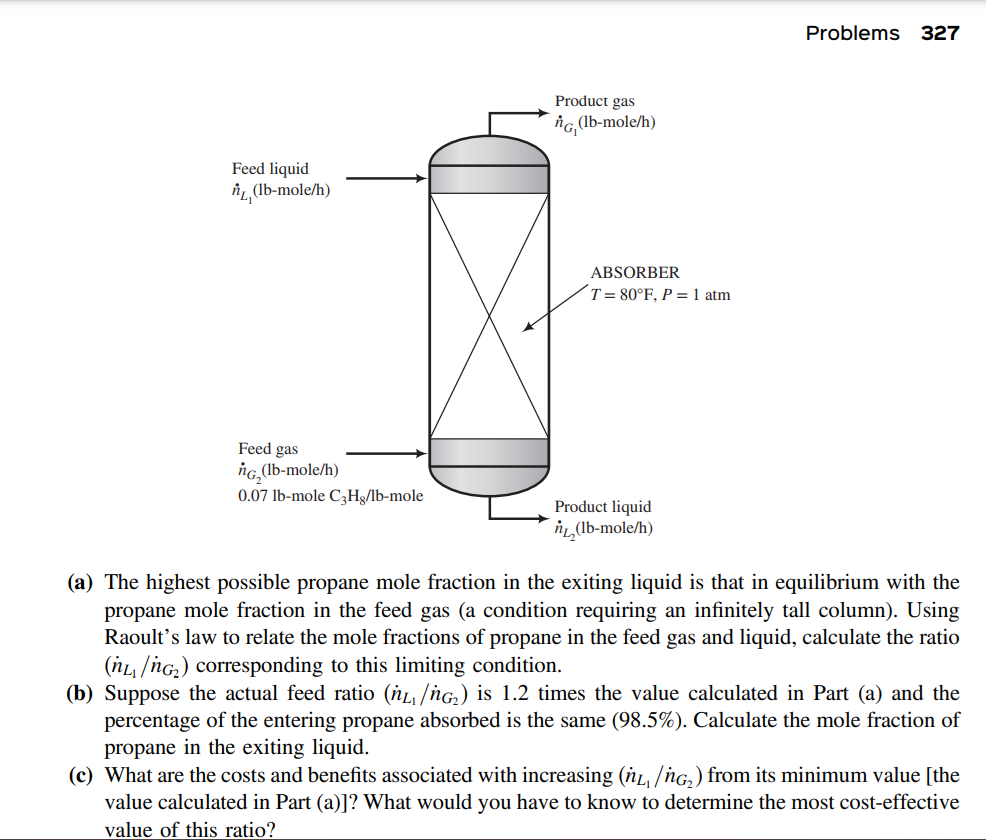

Question: 6 . 4 1 . An important parameter in the design of gas absorbers is the ratio of the flow rate of the feed liquid

An important parameter in the design of gas absorbers is the ratio of the flow rate of the feed liquid to that of the feed gas. The lower the value of this ratio, the lower the cost of the solvent required to process a given quantity of gas but the taller the absorber must be to achieve a specified separation. Propane is recovered from a mole propane nitrogen mixture by contacting the mixture with liquid ndecane. An insignificant amount of decane is vaporized in the process, and of the propane entering the unit is absorbed

a The highest possible propane mole fraction in the exiting liquid is that in equilibrium with the

propane mole fraction in the feed gas a condition requiring an infinitely tall column Using

Raoult's law to relate the mole fractions of propane in the feed gas and liquid, calculate the ratio

corresponding to this limiting condition.

b Suppose the actual feed ratio is times the value calculated in Part a and the

percentage of the entering propane absorbed is the same Calculate the mole fraction of

propane in the exiting liquid.

c What are the costs and benefits associated with increasing from its minimum value the

value calculated in Part a What would you have to know to determine the most costeffective

value of this ratio?

The problem was extracted from Elementary Principles of Chemical Processes

Richard M Felder, Ronald W Rousseau, Lisa G Bullard ed

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock