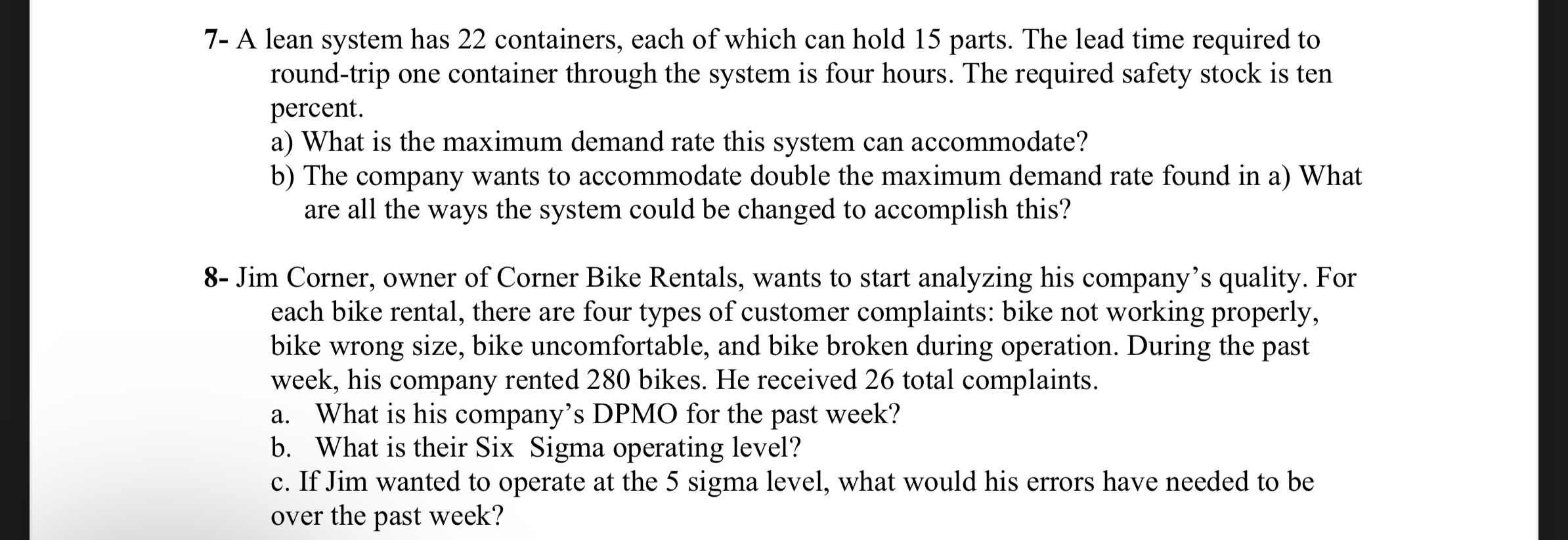

Question: 7 - A lean system has 2 2 containers, each of which can hold 1 5 parts. The lead time required to round - trip

A lean system has containers, each of which can hold parts. The lead time required to roundtrip one container through the system is four hours. The required safety stock is ten percent.

a What is the maximum demand rate this system can accommodate?

b The company wants to accommodate double the maximum demand rate found in a What are all the ways the system could be changed to accomplish this?

Jim Corner, owner of Corner Bike Rentals, wants to start analyzing his company's quality. For each bike rental, there are four types of customer complaints: bike not working properly, bike wrong size, bike uncomfortable, and bike broken during operation. During the past week, his company rented bikes. He received total complaints.

a What is his company's DPMO for the past week?

b What is their Six Sigma operating level?

c If Jim wanted to operate at the sigma level, what would his errors have needed to be over the past week?

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock