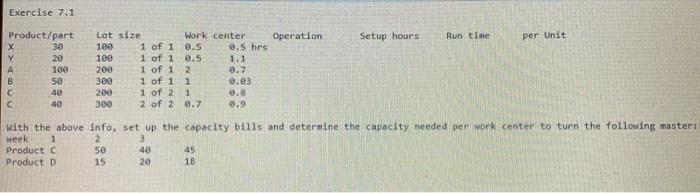

Question: 7.1, 7.8 Exercise 7.1 Setup hours Run tine per Unit Product/part 30 Y 20 A 100 B 50 40 C 40 Lot size work center

7.1, 7.8

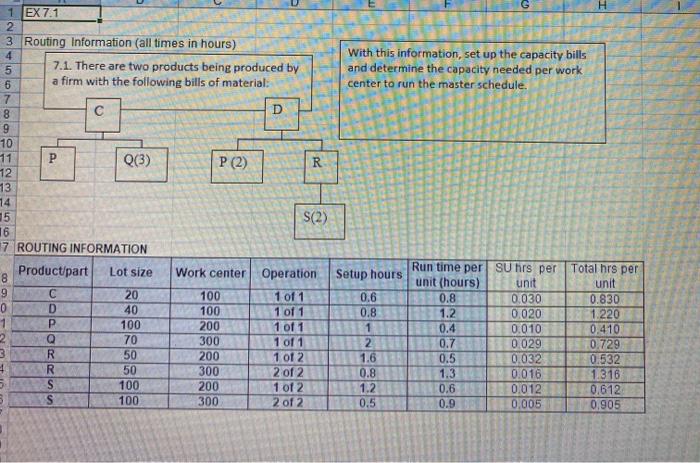

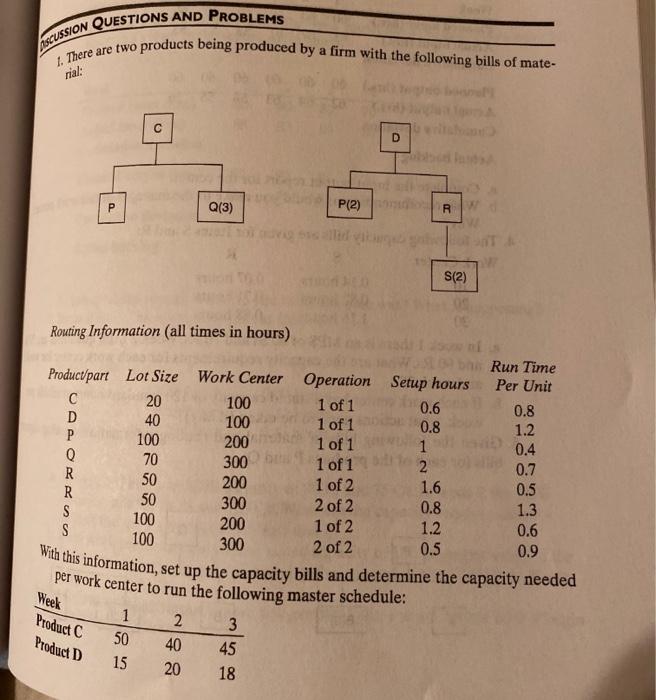

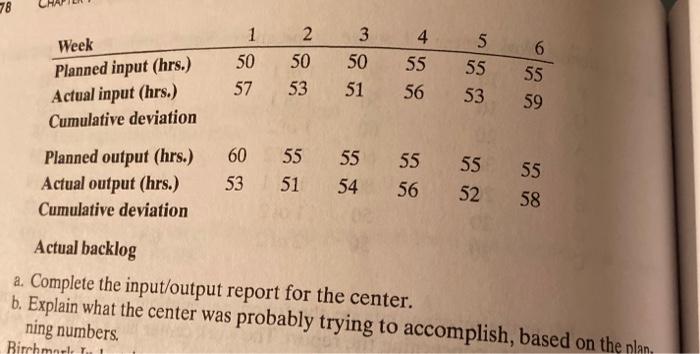

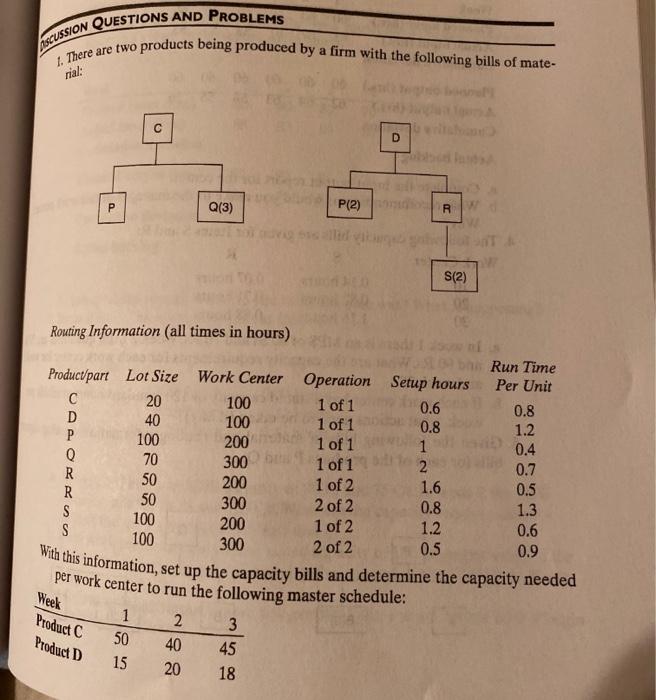

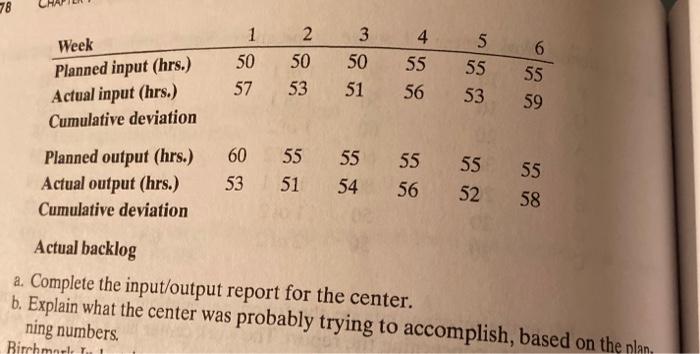

Exercise 7.1 Setup hours Run tine per Unit Product/part 30 Y 20 A 100 B 50 40 C 40 Lot size work center Operation 100 1 of 1 0.5 0.5 hrs 100 1 of 10.5 1.1 200 1 of 1 2 0.7 300 1 of 1 1 0.03 200 1 of 2 1 0.8 300 2 of 2 0.7 0.9 1 2 With the above info, set up the capacity bills and determine the capacity needed per work center to turn the following master: week Product C 50 15 20 3 40 45 18 Product D R 1 EX 7.1 2 3 Routing Information (all times in hours) 4 With this information, set up the capacity bills 5 7.1. There are two products being produced by and determine the capacity needed per work 6 a firm with the following bills of material: center to run the master schedule. 7 D 8 9 10 11 P Q(3) P (2) 12 13 14 5 S(2) 16 17 ROUTING INFORMATION Product/part Lot size Work center Run time per SU hrs per Operation Setup hours Total hrs per unit (hours) unit unit 9 C 20 100 1 of 1 0.6 0.8 0.030 0.830 0 D 40 100 1 of 1 0.8 1.2 0.020 1.220 1 P 100 200 1 of 1 1 0.4 0.010 0.410 2 Q 70 300 1 of 1 2 0.7 0.029 0.729 3 50 200 1 of 2 1.6 0.5 0.032 0.532 4 R 300 2 of 2 0.8 1.3 0.016 1.316 3 S 100 200 1 of 2 1.2 0.6 0.012 0.612 5 S 100 300 2 of 2 0.5 0.9 0.005 0.905 00 C 50 rial: P P(2) ASCUSSION QUESTIONS AND PROBLEMS 1. There are two products being produced by a firm with the following bills of mate- With this information, set up the capacity bills and determine the capacity needed D Q(3) R S(2) 09 Routing Information (all times in hours) Run Time Product/part Lot Size Work Center Operation Setup hours Per Unit 20 100 1 of 1 0.6 0.8 D 40 100 1 of 1 0.8 1.2 P 100 200 1 of 1 1 0.4 Q 70 300 1 of 1 2 0.7 R 50 200 1 of 2 1.6 R 0.5 50 300 2 of 2 0.8 1.3 S 100 200 1 of 2 1.2 0.6 100 300 2 of 2 0.5 0.9 S per work center to run the following master schedule: Week Product C Product D 1 50 15 2 40 20 3 45 18 8. The following input/output report was prepared for a work center with a begin- ning backlog of 23 hours: 78 1 2 50 56 Week Planned input (hrs.) Actual input (hrs.) Cumulative deviation 50 57 3 4 50 55 55 55 51 56 53 59 53 Planned output (hrs.) Actual output (hrs.) Cumulative deviation 60 55 55 55 55 55 53 51 54 56 52 58 Actual backlog a. Complete the input/output report for the center. b. Explain what the center was probably trying to accomplish, based on the nlan. ning numbers. Birchmarlo Exercise 7.1 Setup hours Run tine per Unit Product/part 30 Y 20 A 100 B 50 40 C 40 Lot size work center Operation 100 1 of 1 0.5 0.5 hrs 100 1 of 10.5 1.1 200 1 of 1 2 0.7 300 1 of 1 1 0.03 200 1 of 2 1 0.8 300 2 of 2 0.7 0.9 1 2 With the above info, set up the capacity bills and determine the capacity needed per work center to turn the following master: week Product C 50 15 20 3 40 45 18 Product D R 1 EX 7.1 2 3 Routing Information (all times in hours) 4 With this information, set up the capacity bills 5 7.1. There are two products being produced by and determine the capacity needed per work 6 a firm with the following bills of material: center to run the master schedule. 7 D 8 9 10 11 P Q(3) P (2) 12 13 14 5 S(2) 16 17 ROUTING INFORMATION Product/part Lot size Work center Run time per SU hrs per Operation Setup hours Total hrs per unit (hours) unit unit 9 C 20 100 1 of 1 0.6 0.8 0.030 0.830 0 D 40 100 1 of 1 0.8 1.2 0.020 1.220 1 P 100 200 1 of 1 1 0.4 0.010 0.410 2 Q 70 300 1 of 1 2 0.7 0.029 0.729 3 50 200 1 of 2 1.6 0.5 0.032 0.532 4 R 300 2 of 2 0.8 1.3 0.016 1.316 3 S 100 200 1 of 2 1.2 0.6 0.012 0.612 5 S 100 300 2 of 2 0.5 0.9 0.005 0.905 00 C 50 rial: P P(2) ASCUSSION QUESTIONS AND PROBLEMS 1. There are two products being produced by a firm with the following bills of mate- With this information, set up the capacity bills and determine the capacity needed D Q(3) R S(2) 09 Routing Information (all times in hours) Run Time Product/part Lot Size Work Center Operation Setup hours Per Unit 20 100 1 of 1 0.6 0.8 D 40 100 1 of 1 0.8 1.2 P 100 200 1 of 1 1 0.4 Q 70 300 1 of 1 2 0.7 R 50 200 1 of 2 1.6 R 0.5 50 300 2 of 2 0.8 1.3 S 100 200 1 of 2 1.2 0.6 100 300 2 of 2 0.5 0.9 S per work center to run the following master schedule: Week Product C Product D 1 50 15 2 40 20 3 45 18 8. The following input/output report was prepared for a work center with a begin- ning backlog of 23 hours: 78 1 2 50 56 Week Planned input (hrs.) Actual input (hrs.) Cumulative deviation 50 57 3 4 50 55 55 55 51 56 53 59 53 Planned output (hrs.) Actual output (hrs.) Cumulative deviation 60 55 55 55 55 55 53 51 54 56 52 58 Actual backlog a. Complete the input/output report for the center. b. Explain what the center was probably trying to accomplish, based on the nlan. ning numbers. Birchmarlo

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock