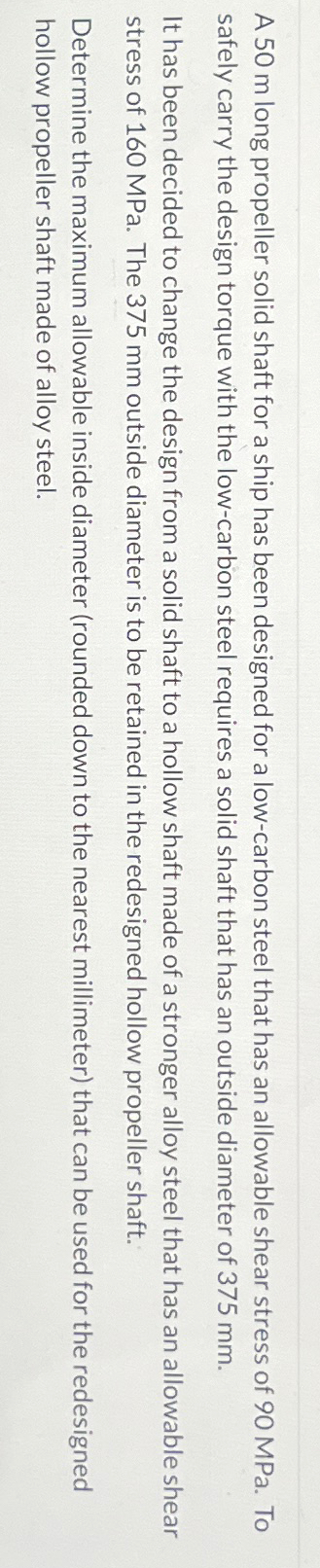

Question: A 5 0 m long propeller solid shaft for a ship has been designed for a low - carbon steel that has an allowable shear

A long propeller solid shaft for a ship has been designed for a lowcarbon steel that has an allowable shear stress of MPa. To safely carry the design torque with the lowcarbon steel requires a solid shaft that has an outside diameter of

It has been decided to change the design from a solid shaft to a hollow shaft made of a stronger alloy steel that has an allowable shear stress of MPa. The outside diameter is to be retained in the redesigned hollow propeller shaft.

Determine the maximum allowable inside diameter rounded down to the nearest millimeter that can be used for the redesigned hollow propeller shaft made of alloy steel.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock