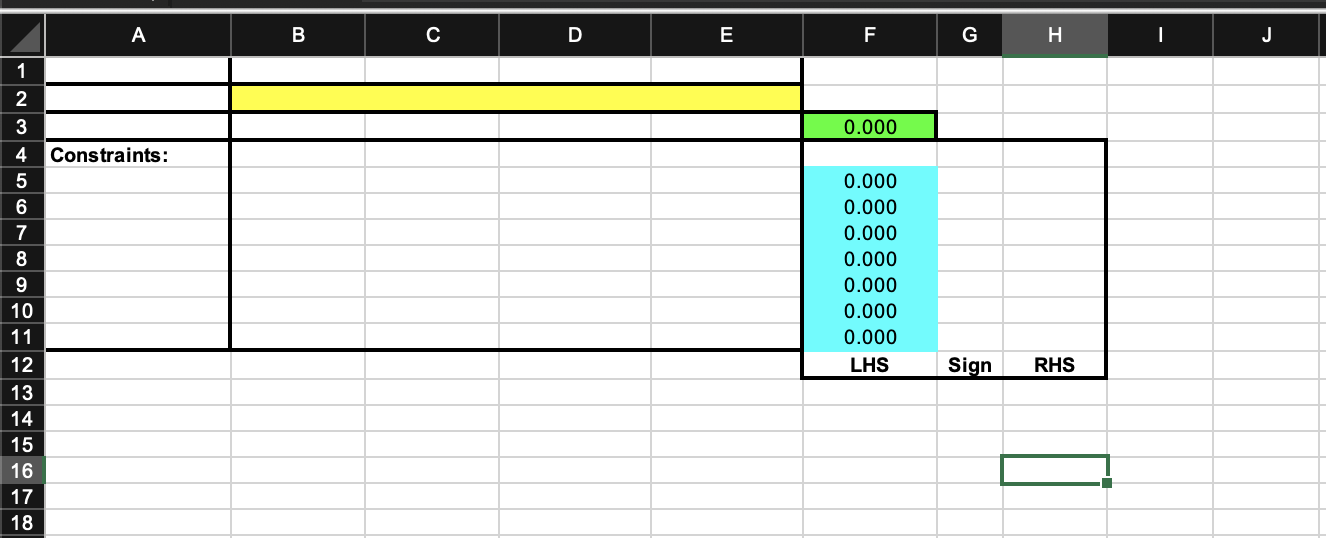

Question: A B C D E F G H 2 3 0.000 4 Constraints: 5 6 0.000 7 0.000 0.000 8 9 0.000 10 0.000 11

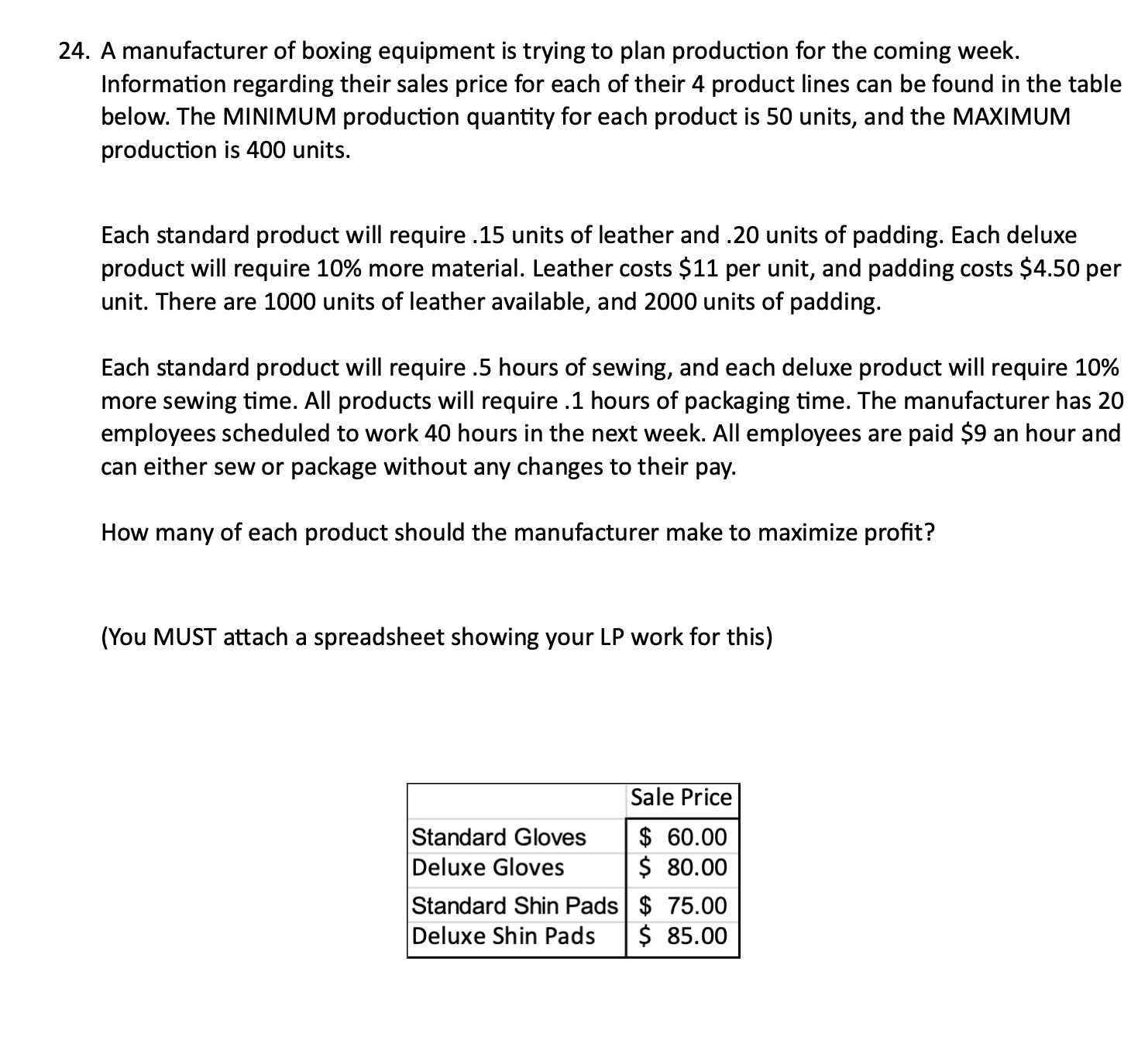

A B C D E F G H 2 3 0.000 4 Constraints: 5 6 0.000 7 0.000 0.000 8 9 0.000 10 0.000 11 0.000 0.000 12 LHS Sign 13 RHS 14 15 16 17 1824. A manufacturer of boxing equipment is trying to plan production for the coming week. Information regarding their sales price for each of their 4 product lines can be found in the table below. The MINIMUM production quantity for each product is 50 units, and the MAXIMUM production is 400 units. Each standard product will require .15 units of leather and .20 units of padding. Each deluxe product will require 10% more material. Leather costs $11 per unit, and padding costs $4.50 per unit. There are 1000 units of leather available, and 2000 units of padding. Each standard product will require .5 hours of sewing, and each deluxe product will require 10% more sewing time. All products will require .1 hours of packaging time. The manufacturer has 20 employees scheduled to work 40 hours in the next week. All employees are paid $9 an hour and can either sew or package without any changes to their pay. How many of each product should the manufacturer make to maximize prot? (You MUST attach a spreadsheet showing your LP work for this) Sale Price Standard Gloves Deluxe Gloves Standard Shin Pads $ 75.00 Deluxe Shin Pads

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts