Question: A flow shop with parallel processors consists of m processing stages in series with unlimited capacity buffers between the stage successive stages, and each stage

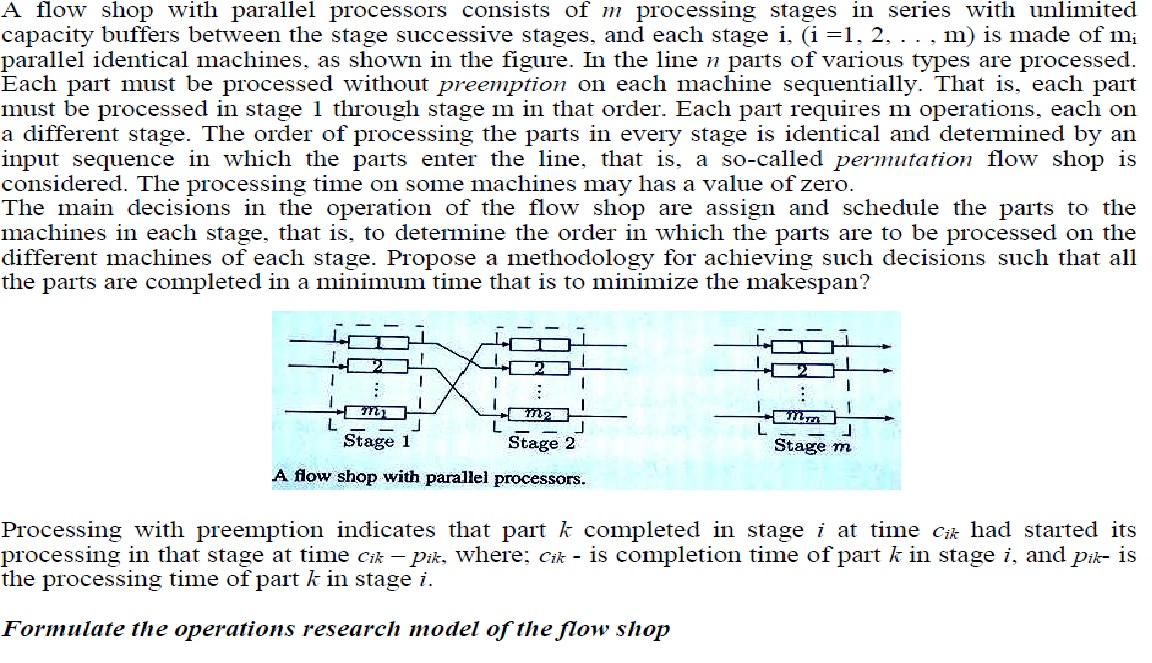

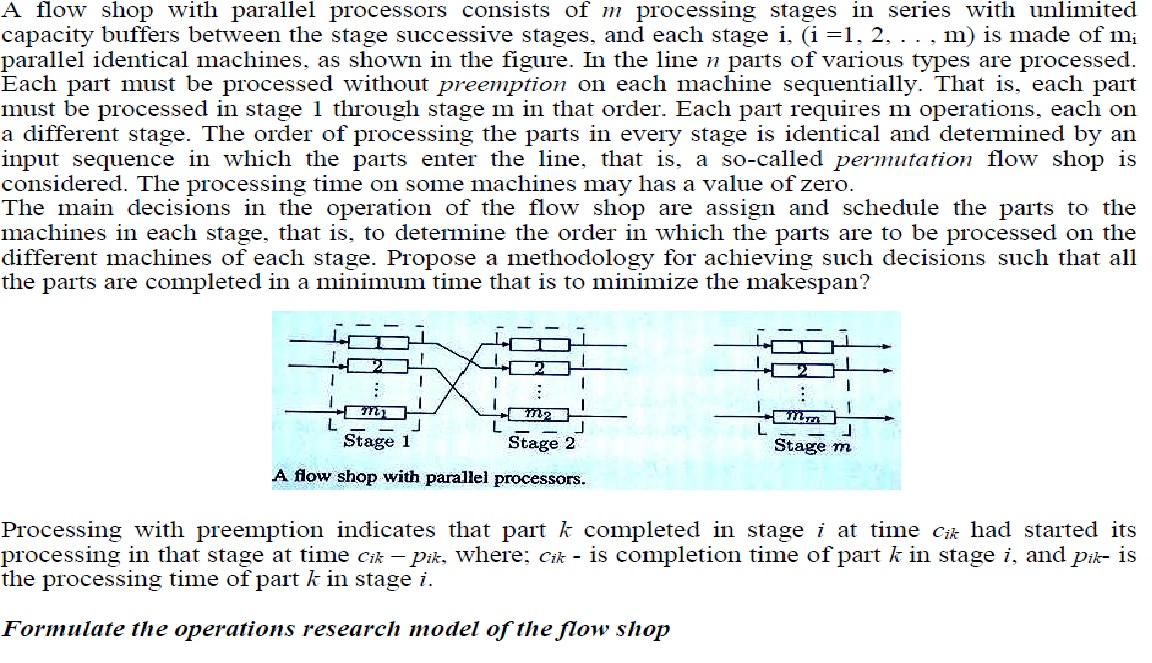

A flow shop with parallel processors consists of m processing stages in series with unlimited capacity buffers between the stage successive stages, and each stage i, (i =1, 2, .. ,m) is made of mi parallel identical machines, as shown in the figure. In the line n parts of various types are processed. Each part must be processed without preemption on each machine sequentially. That is, each part must be processed in stage 1 through stage m in that order. Each part requires m operations, each on a different stage. The order of processing the parts in every stage is identical and determined by an input sequence in which the parts enter the line, that is, a so-called permutation flow shop is considered. The processing time on some machines may has a value of zero. The main decisions in the operation of the flow shop are assign and schedule the parts to the machines in each stage, that is, to determine the order in which the parts are to be processed on the different machines of each stage. Propose a methodology for achieving such decisions such that all the parts are completed in a minimum time that is to minimize the makespan? 1 1 1 1 1 1 1 L Stage 1 L Stage 2 Stage m A flow shop with parallel processors. Processing with preemption indicates that part k completed in stage i at time Cik had started its processing in that stage at time Cik - Pik, where; Cik - is completion time of part k in stage i, and pik- is the processing time of part k in stage i. Formulate the operations research model of the flow shop A flow shop with parallel processors consists of m processing stages in series with unlimited capacity buffers between the stage successive stages, and each stage i, (i =1, 2, .. ,m) is made of mi parallel identical machines, as shown in the figure. In the line n parts of various types are processed. Each part must be processed without preemption on each machine sequentially. That is, each part must be processed in stage 1 through stage m in that order. Each part requires m operations, each on a different stage. The order of processing the parts in every stage is identical and determined by an input sequence in which the parts enter the line, that is, a so-called permutation flow shop is considered. The processing time on some machines may has a value of zero. The main decisions in the operation of the flow shop are assign and schedule the parts to the machines in each stage, that is, to determine the order in which the parts are to be processed on the different machines of each stage. Propose a methodology for achieving such decisions such that all the parts are completed in a minimum time that is to minimize the makespan? 1 1 1 1 1 1 1 L Stage 1 L Stage 2 Stage m A flow shop with parallel processors. Processing with preemption indicates that part k completed in stage i at time Cik had started its processing in that stage at time Cik - Pik, where; Cik - is completion time of part k in stage i, and pik- is the processing time of part k in stage i. Formulate the operations research model of the flow shop