Question: (a) Identify the bottleneck activity on this operation process chart. (b) What is the cycle time for the bottleneck activity? (c) Calculate the number of

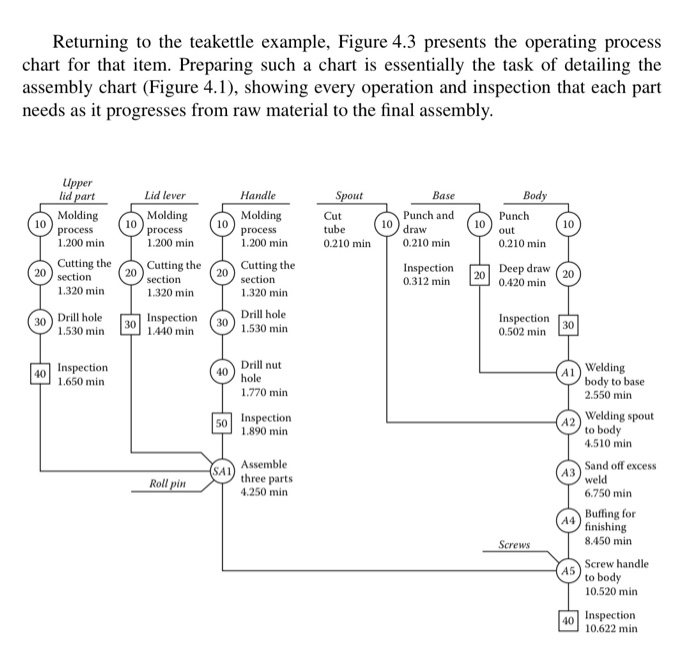

(a) Identify the bottleneck activity on this operation process chart.

(b) What is the cycle time for the bottleneck activity?

(c) Calculate the number of teakettles that can be produced in an 8 hour shift (400 min.), assuming that one worker is assigned to handle each production activity (including operation, inspection and assembly).

(d) Explain why this is not an efficient way (i.e., one worker per operation) to produce teakettles.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock