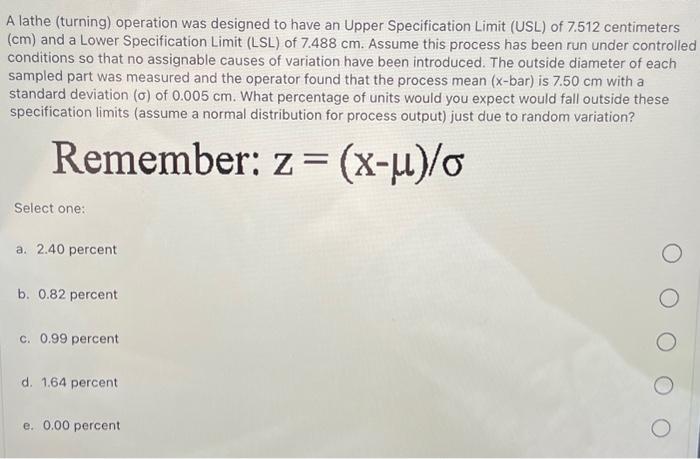

Question: A lathe (turning) operation was designed to have an Upper Specification Limit (USL) of 7.512 centimeters (cm) and a Lower Specification Limit (LSL) of 7.488cm.

A lathe (turning) operation was designed to have an Upper Specification Limit (USL) of 7.512 centimeters (cm) and a Lower Specification Limit (LSL) of 7.488cm. Assume this process has been run under controlled conditions so that no assignable causes of variation have been introduced. The outside diameter of each sampled part was measured and the operator found that the process mean (xbar) is 7.50cm with a standard deviation () of 0.005cm. What percentage of units would you expect would fall outside these specification limits (assume a normal distribution for process output) just due to random variation? Remember: z=(x)/ Select one: a. 2.40 percent b. 0.82 percent c. 0.99 percent d. 1.64 percent e. 0.00 percent A lathe (turning) operation was designed to have an Upper Specification Limit (USL) of 7.512 centimeters (cm) and a Lower Specification Limit (LSL) of 7.488cm. Assume this process has been run under controlled conditions so that no assignable causes of variation have been introduced. The outside diameter of each sampled part was measured and the operator found that the process mean (xbar) is 7.50cm with a standard deviation () of 0.005cm. What percentage of units would you expect would fall outside these specification limits (assume a normal distribution for process output) just due to random variation? Remember: z=(x)/ Select one: a. 2.40 percent b. 0.82 percent c. 0.99 percent d. 1.64 percent e. 0.00 percent

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts