Question: MAKE PROGRAM C-CODE BASED ON INSTRUCTION AND OUTPUT BELOW: 5. Each program ANALYSIS MUST CONSIST: total part machining time, total energy consumption, total operation cost,

MAKE PROGRAM C-CODE BASED ON INSTRUCTION AND OUTPUT BELOW:

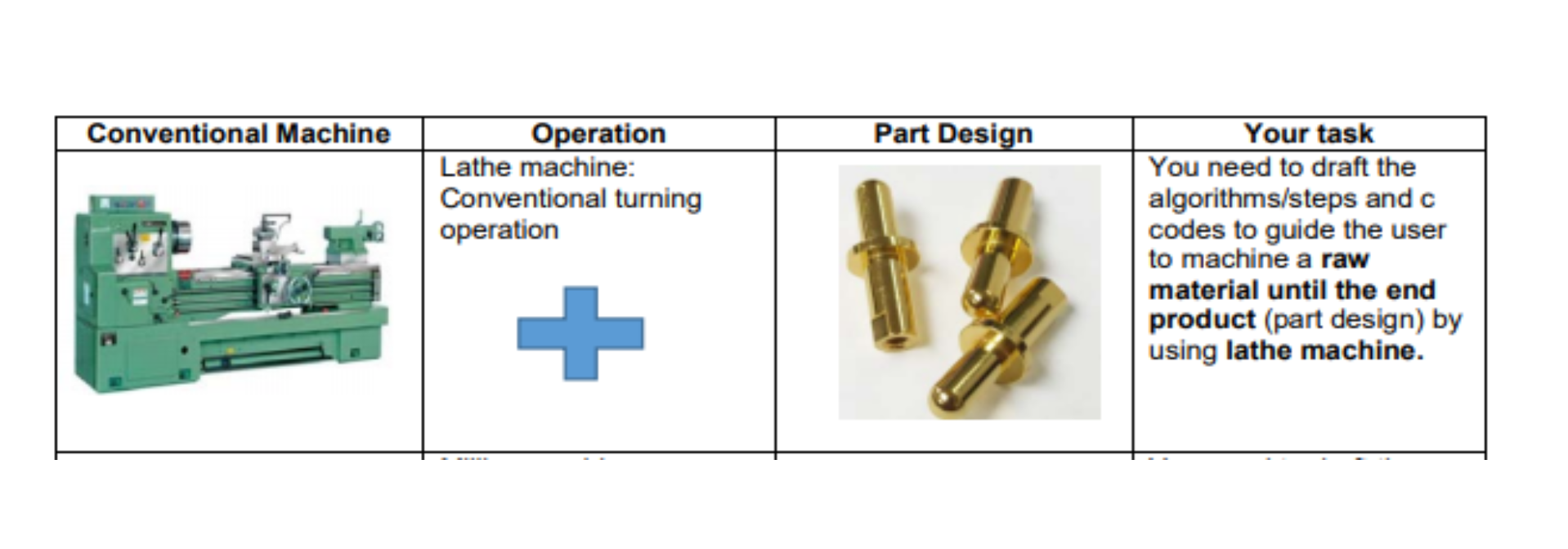

5. Each program ANALYSIS MUST CONSIST: total part machining time, total energy consumption, total operation cost, by-products or solid waste generation in kg, and estimated productivity per 8 hours working. 6. Your program MUST shows the DETAILS STEPS and PARAMETERS & CORRECT CALCULATION TO machine raw material until you get the end product (part design). Your program: 1. The conventional machines specifications and limitations (e.g. size of allowed material dimensions) 2. Details steps/guidelines to machine until you get a part design (e.g. facing=reducing diameter threading). 3. Each program must consist AT LEAST 5 operational steps to complete a part machining. 4. Each program MUST consists at least 2"function, 2for looping, Decision Operators and Array. 5. Each program MUST shows the analysis results: part machining time, total energy consumption, total operation cost, by-products or solid waste generation, and estimated productivity per day. Conventional Machine Part Design Operation Lathe machine: Conventional turning operation Your task You need to draft the algorithms/steps and c codes to guide the user to machine a raw material until the end product (part design) by using lathe machine. + 5. Each program ANALYSIS MUST CONSIST: total part machining time, total energy consumption, total operation cost, by-products or solid waste generation in kg, and estimated productivity per 8 hours working. 6. Your program MUST shows the DETAILS STEPS and PARAMETERS & CORRECT CALCULATION TO machine raw material until you get the end product (part design). Your program: 1. The conventional machines specifications and limitations (e.g. size of allowed material dimensions) 2. Details steps/guidelines to machine until you get a part design (e.g. facing=reducing diameter threading). 3. Each program must consist AT LEAST 5 operational steps to complete a part machining. 4. Each program MUST consists at least 2"function, 2for looping, Decision Operators and Array. 5. Each program MUST shows the analysis results: part machining time, total energy consumption, total operation cost, by-products or solid waste generation, and estimated productivity per day. Conventional Machine Part Design Operation Lathe machine: Conventional turning operation Your task You need to draft the algorithms/steps and c codes to guide the user to machine a raw material until the end product (part design) by using lathe machine. +

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts