Question: A mixing drum needs to be designed to blend 150 kg cement. When mixing, the machine is inclined at angle 45 to 60 from

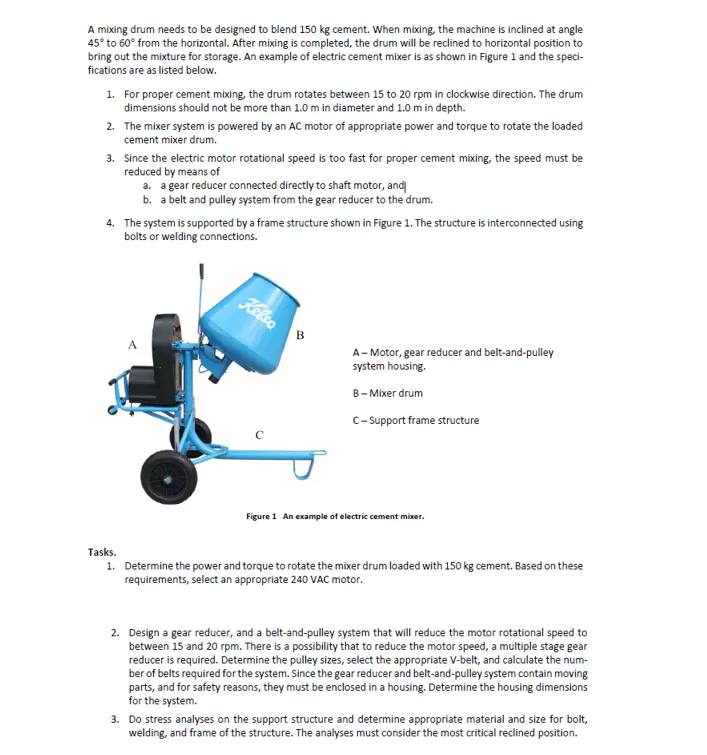

A mixing drum needs to be designed to blend 150 kg cement. When mixing, the machine is inclined at angle 45 to 60 from the horizontal. After mixing is completed, the drum will be reclined to horizontal position to bring out the mixture for storage. An example of electric cement mixer is as shown in Figure 1 and the speci- fications are as listed below. 1. For proper cement mixing, the drum rotates between 15 to 20 rpm in clockwise direction. The drum dimensions should not be more than 1.0 m in diameter and 1.0 m in depth. 2. The mixer system is powered by an AC motor of appropriate power and torque to rotate the loaded cement mixer drum. 3. Since the electric motor rotational speed is too fast for proper cement mixing, the speed must be reduced by means of a. a gear reducer connected directly to shaft motor, and b. a belt and pulley system from the gear reducer to the drum. 4. The system is supported by a frame structure shown in Figure 1. The structure is interconnected using bolts or welding connections. Kelso B A-Motor, gear reducer and belt-and-pulley system housing. B-Mixer drum C-Support frame structure Figure 1 An example of electric cement mixer. Tasks. 1. Determine the power and torque to rotate the mixer drum loaded with 150 kg cement. Based on these requirements, select an appropriate 240 VAC motor. 2. Design a gear reducer, and a belt-and-pulley system that will reduce the motor rotational speed to between 15 and 20 rpm. There is a possibility that to reduce the motor speed, a multiple stage gear reducer is required. Determine the pulley sizes, select the appropriate V-belt, and calculate the num- ber of belts required for the system. Since the gear reducer and belt-and-pulley system contain moving parts, and for safety reasons, they must be enclosed in a housing. Determine the housing dimensions for the system. 3. Do stress analyses on the support structure and determine appropriate material and size for bolt, welding, and frame of the structure. The analyses must consider the most critical reclined position.

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts