Question: A project is about placing reinforcing steel into a precast slab. The project manager employs two skilled steel setters (also called rodmen on site)

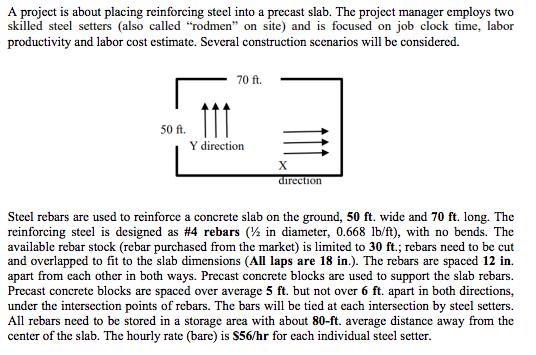

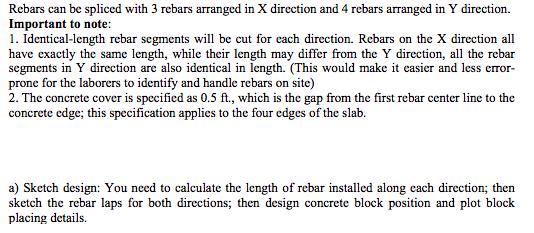

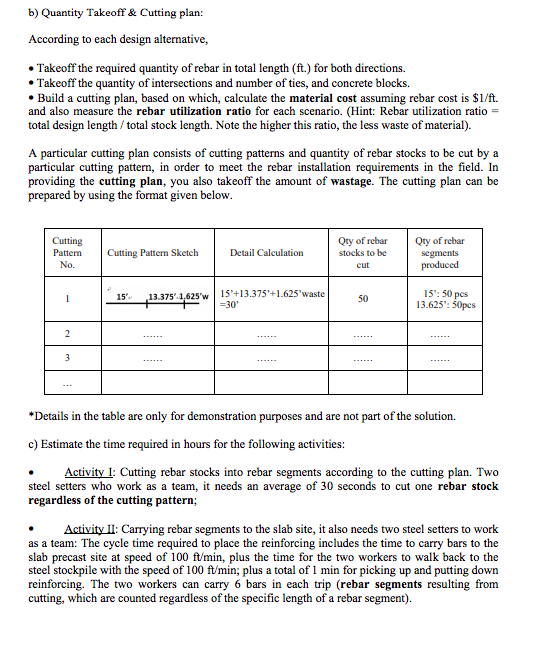

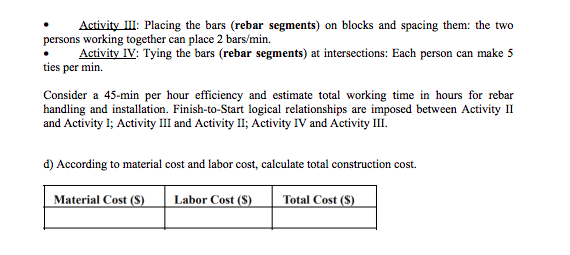

A project is about placing reinforcing steel into a precast slab. The project manager employs two skilled steel setters (also called "rodmen" on site) and is focused on job clock time, labor productivity and labor cost estimate. Several construction scenarios will be considered. 50 ft. 70 ft. Y direction X direction Steel rebars are used to reinforce a concrete slab on the ground, 50 ft. wide and 70 ft. long. The reinforcing steel is designed as #4 rebars ( in diameter, 0.668 lb/ft), with no bends. The available rebar stock (rebar purchased from the market) is limited to 30 ft.; rebars need to be cut and overlapped to fit to the slab dimensions (All laps are 18 in.). The rebars are spaced 12 in. apart from each other in both ways. Precast concrete blocks are used to support the slab rebars. Precast concrete blocks are spaced over average 5 ft. but not over 6 ft. apart in both directions, under the intersection points of rebars. The bars will be tied at each intersection by steel setters. All rebars need to be stored in a storage area with about 80-ft. average distance away from the center of the slab. The hourly rate (bare) is $56/hr for each individual steel setter. Rebars can be spliced with 3 rebars arranged in X direction and 4 rebars arranged in Y direction. Important to note: 1. Identical-length rebar segments will be cut for each direction. Rebars on the X direction all have exactly the same length, while their length may differ from the Y direction, all the rebar segments in Y direction are also identical in length. (This would make it easier and less error- prone for the laborers to identify and handle rebars on site) 2. The concrete cover is specified as 0.5 ft., which is the gap from the first rebar center line to the concrete edge; this specification applies to the four edges of the slab. a) Sketch design: You need to calculate the length of rebar installed along each direction; then sketch the rebar laps for both directions; then design concrete block position and plot block placing details. b) Quantity Takeoff & Cutting plan: According to each design alternative, Takeoff the required quantity of rebar in total length (ft.) for both directions. Takeoff the quantity of intersections and number of ties, and concrete blocks. Build a cutting plan, based on which, calculate the material cost assuming rebar cost is $1/ft. and also measure the rebar utilization ratio for each scenario. (Hint: Rebar utilization ratio = total design length / total stock length. Note the higher this ratio, the less waste of material). A particular cutting plan consists of cutting patterns and quantity of rebar stocks to be cut by a particular cutting pattern, in order to meet the rebar installation requirements in the field. In providing the cutting plan, you also takeoff the amount of wastage. The cutting plan can be prepared by using the format given below. Cutting Pattern No. 1 2 3 Cutting Pattern Sketch 15% 13.375' 1,625'w Detail Calculation 15'+13.375 +1.625'waste Qty of rebar stocks to be cut 50 Qty of rebar segments produced 15': 50 pcs 13.625': 50pcs *Details in the table are only for demonstration purposes and are not part of the solution. c) Estimate the time required in hours for the following activities: Activity 1: Cutting rebar stocks into rebar segments according to the cutting plan. Two steel setters who work as a team, it needs an average of 30 seconds to cut one rebar stock regardless of the cutting pattern; Activity II: Carrying rebar segments to the slab site, it also needs two steel setters to work as a team: The cycle time required to place the reinforcing includes the time to carry bars to the slab precast site at speed of 100 ft/min, plus the time for the two workers to walk back to the steel stockpile with the speed of 100 ft/min; plus a total of 1 min for picking up and putting down reinforcing. The two workers can carry 6 bars in each trip (rebar segments resulting from cutting, which are counted regardless of the specific length of a rebar segment). Activity III: Placing the bars (rebar segments) on blocks and spacing them: the two persons working together can place 2 bars/min. Activity IV: Tying the bars (rebar segments) at intersections: Each person can make 5 ties per min. Consider a 45-min per hour efficiency and estimate total working time in hours for rebar handling and installation. Finish-to-Start logical relationships are imposed between Activity II and Activity I; Activity III and Activity II; Activity IV and Activity III. d) According to material cost and labor cost, calculate total construction cost. Material Cost (S) Labor Cost (S) Total Cost (S)

Step by Step Solution

3.39 Rating (155 Votes )

There are 3 Steps involved in it

To tackle this problem we need to address each part systematically Part a Sketch Design 1 Calculate the Length of Rebar for Each Direction ... View full answer

Get step-by-step solutions from verified subject matter experts