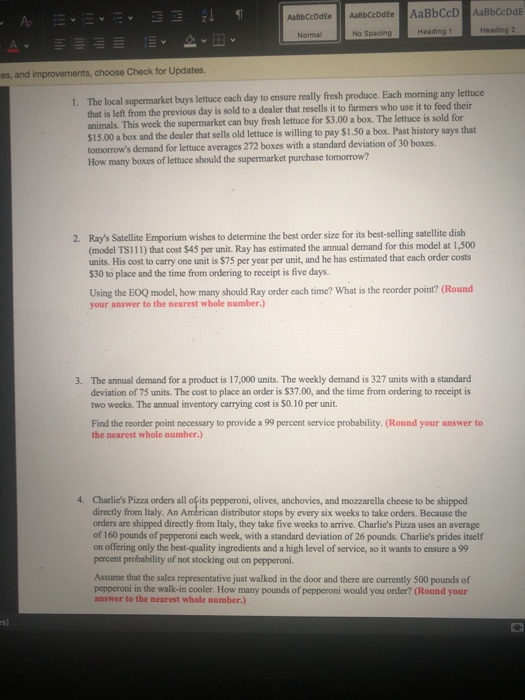

Question: - A review 3 1 1 AaBbccdEe Aalbeddee No Spacing AaBbCcD Heading 1 AaBbCeDdE Heading 2 Normal es, and improvements, choose Check for Updates. 1.

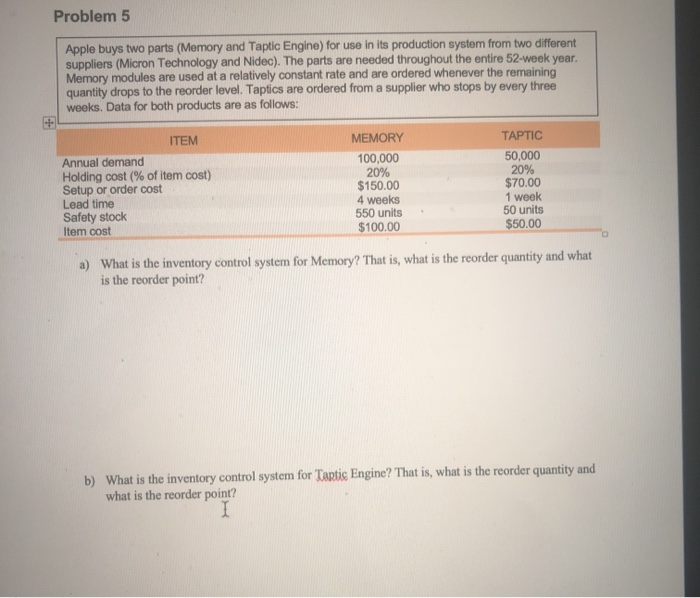

- A review 3 1 1 AaBbccdEe Aalbeddee No Spacing AaBbCcD Heading 1 AaBbCeDdE Heading 2 Normal es, and improvements, choose Check for Updates. 1. The local supermarket buys lettuce each day to ensure really fresh produce. Each moming any lettuce that is left from the previous day is sold to a dealer that resells it to farmers who use it to feed their animals. This week the supermarket can buy fresh lettuce for $3.00 a box. The lettuce is sold for $15.00 a box and the dealer that sells old lettuce is willing to pay $1.50 a box. Past history says that tomorrow's demand for lettuce averages 272 boxes with a standard deviation of 30 boxes. How many boxes of lettuce should the supermarket purchase tomorrow? 2. Ray's Satellite Emporium wishes to determine the best order size for its best-selling satellite dish (model TS111) that cost $45 per unit. Ray has estimated the annual demand for this model at 1,500 units. His cost to carry one unit is $75 per year per unit, and he has estimated that each order costs $30 to place and the time from ordering to receipt is five days. Using the EOQ model, how many should Ray order each time? What is the reorder point? (Round your answer to the nearest whole number.) 3. The annual demand for a product is 17,000 units. The weekly demand is 327 units with a standard deviation of 75 units. The cost to place an order is $37.00, and the time from ordering to receipt is two weeks. The annual inventory carrying cost is $0.10 per unit. Find the reorder point necessary to provide a 99 percent service probability. (Round your answer to the nearest whole number.) 4. Charlie's Pizza orders all ofits pepperoni, olives, anchovies, and mozzarella cheese to be shipped directly from Italy. An American distributor stops by every six weeks to take orders. Because the orders are shipped directly from Italy, they take five weeks to arrive. Charlie's Pizza uses an average of 160 pounds of pepperoni each week, with a standard deviation of 26 pounds, Charlie's prides itself on offering only the best quality ingredients and a high level of service, so it wants to ensure a 99 percent probability of not stocking out on pepperoni. Assume that the sales representative just walked in the door and there are currently 500 pounds of pepperoni in the walk-in cooler. How many pounds of pepperoni would you order? (Round your answer to the nearest whole number.) Problem 5 Apple buys two parts (Memory and Taptic Engine) for use in its production system from two different suppliers (Micron Technology and Nidec). The parts are needed througho Memory modules are used at a relatively constant rate and are ordered whenever the remaining quantity drops to the reorder level. Taptics are ordered from a supplier who stops by every three weeks. Data for both products are as follows: ITEM Annual demand Holding cost (% of item cost) Setup or order cost Lead time Safety stock Item cost MEMORY 100,000 20% $150.00 4 weeks 550 units $100.00 TAPTIC 50,000 20% $70.00 1 week 50 units $50.00 a) What is the inventory control system for Memory? That is what is the reorder quantity and what is the reorder point? b) What is the inventory control system for Tartic Engine? That is, what is the reorder quantity and what is the reorder point