Question: A therapeutic compound is to be produced in genetically engineered alfalfa plants. To extract the crude compound, which is present at 0.75 wt% in

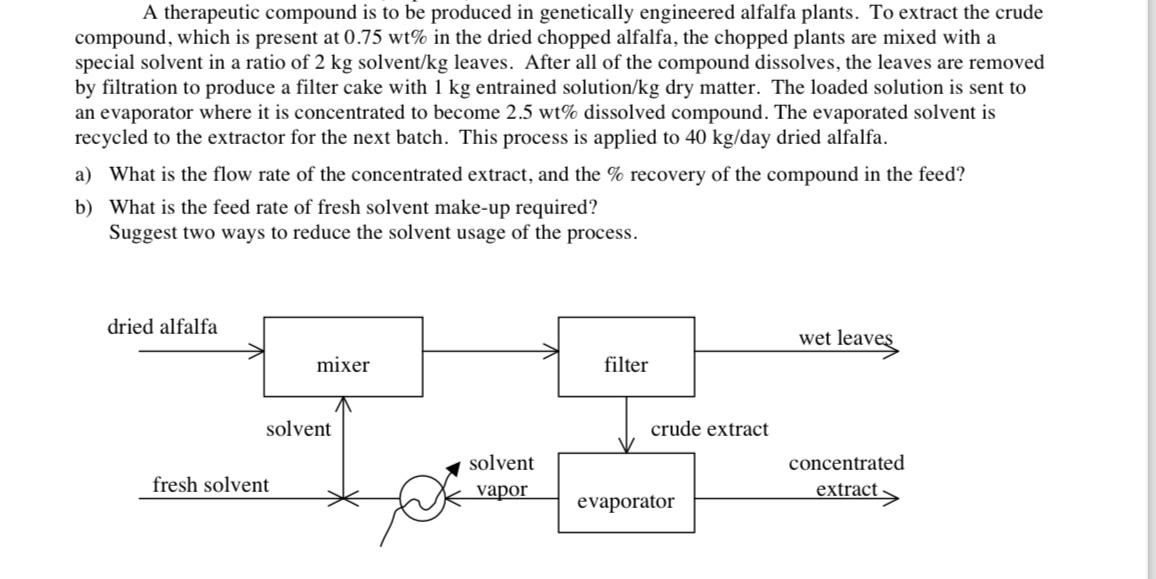

A therapeutic compound is to be produced in genetically engineered alfalfa plants. To extract the crude compound, which is present at 0.75 wt% in the dried chopped alfalfa, the chopped plants are mixed with a special solvent in a ratio of 2 kg solvent/kg leaves. After all of the compound dissolves, the leaves are removed by filtration to produce a filter cake with 1 kg entrained solution/kg dry matter. The loaded solution is sent to an evaporator where it is concentrated to become 2.5 wt% dissolved compound. The evaporated solvent is recycled to the extractor for the next batch. This process is applied to 40 kg/day dried alfalfa. a) What is the flow rate of the concentrated extract, and the % recovery of the compound in the feed? b) What is the feed rate of fresh solvent make-up required? Suggest two ways to reduce the solvent usage of the process. dried alfalfa mixer solvent fresh solvent solvent vapor filter crude extract evaporator wet leaves concentrate extract >

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts