Question: An assembly chart for a simple gate valve is given in figure 1.1, part list and assembly information for the gate valve and processing information

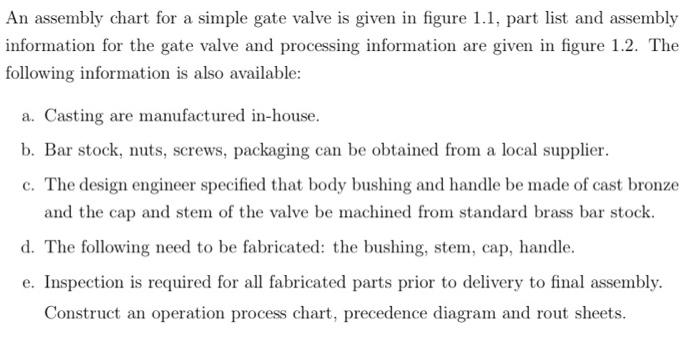

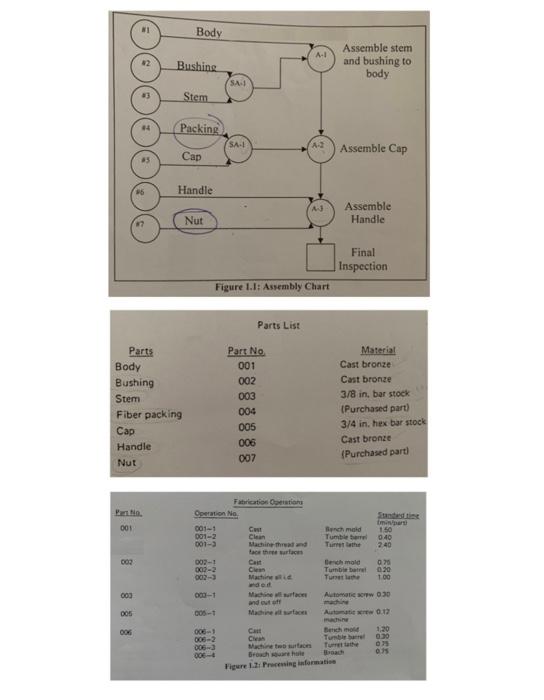

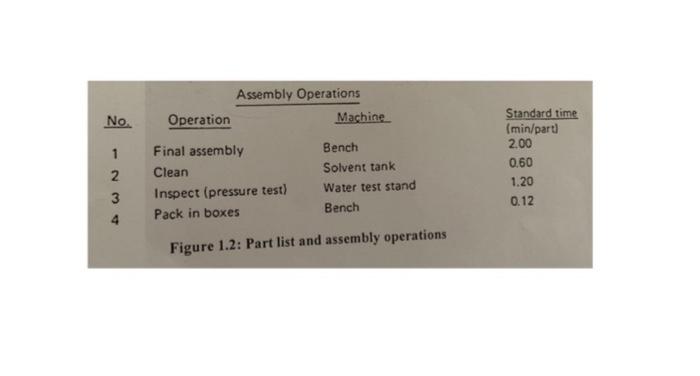

An assembly chart for a simple gate valve is given in figure 1.1, part list and assembly information for the gate valve and processing information are given in figure 1.2. The following information is also available: a. Casting are manufactured in-house. b. Bar stock, nuts, screws, packaging can be obtained from a local supplier. c. The design engineer specified that body bushing and handle be made of cast bronze and the cap and stem of the valve be machined from standard brass bar stock. d. The following need to be fabricated: the bushing, stem, cap, handle. e. Inspection is required for all fabricated parts prior to delivery to final assembly. Construct an operation process chart, precedence diagram and rout sheets. Body A. Bushing Assemble stem and bushing to body SAI Stem Packing SAL A2 Assemble Cap Cap Handle Nut Assemble Handle Final Inspection Figure 1.1: Assembly Chart Parts Body Bushing Stem Fiber packing Cap Handle Nut Parts List Part No 001 002 003 004 005 006 007 Material Cast bronze Cast bronze 3/8 in, bar stock (Purchased part 3/4 in. hex bar stock Cast bronze (Purchased part) 001 Fabrication in Operation No 001-1 001-2 001-3 face the surface 002-1 002-2 0023 Machine Bench maid Tumblr Turn the minant 150 0:40 240 02 Benchmal Turbate Turtle 020 020 1.00 000 0001 Als 030 Mirace and out of Machines 005 005 - Auto w 0.12 006 0001 1.20 030 Benchmo Clean Tube Machine wun Brochure Figure 1. ring informatie 0.15 006- Assembly Operations Operation Machine No. 1 2 3 4 Final assembly Clean Inspect (pressure test) Pack in boxes Bench Solvent tank Water test stand Bench Standard time (min/part 2.00 0.60 1.20 0.12 Figure 1.2: Part list and assembly operations An assembly chart for a simple gate valve is given in figure 1.1, part list and assembly information for the gate valve and processing information are given in figure 1.2. The following information is also available: a. Casting are manufactured in-house. b. Bar stock, nuts, screws, packaging can be obtained from a local supplier. c. The design engineer specified that body bushing and handle be made of cast bronze and the cap and stem of the valve be machined from standard brass bar stock. d. The following need to be fabricated: the bushing, stem, cap, handle. e. Inspection is required for all fabricated parts prior to delivery to final assembly. Construct an operation process chart, precedence diagram and rout sheets. Body A. Bushing Assemble stem and bushing to body SAI Stem Packing SAL A2 Assemble Cap Cap Handle Nut Assemble Handle Final Inspection Figure 1.1: Assembly Chart Parts Body Bushing Stem Fiber packing Cap Handle Nut Parts List Part No 001 002 003 004 005 006 007 Material Cast bronze Cast bronze 3/8 in, bar stock (Purchased part 3/4 in. hex bar stock Cast bronze (Purchased part) 001 Fabrication in Operation No 001-1 001-2 001-3 face the surface 002-1 002-2 0023 Machine Bench maid Tumblr Turn the minant 150 0:40 240 02 Benchmal Turbate Turtle 020 020 1.00 000 0001 Als 030 Mirace and out of Machines 005 005 - Auto w 0.12 006 0001 1.20 030 Benchmo Clean Tube Machine wun Brochure Figure 1. ring informatie 0.15 006- Assembly Operations Operation Machine No. 1 2 3 4 Final assembly Clean Inspect (pressure test) Pack in boxes Bench Solvent tank Water test stand Bench Standard time (min/part 2.00 0.60 1.20 0.12 Figure 1.2: Part list and assembly operations