Question: Analyze the capacity of the process if a setup time of 5 minutes is added to the process of CLEAN, and the production hours of

Analyze the capacity of the process if a setup time of 5 minutes is added to the process of CLEAN, and the production hours of the process of COAT is only 7 hours per day (the other processes still remain 7.5 hours per day)

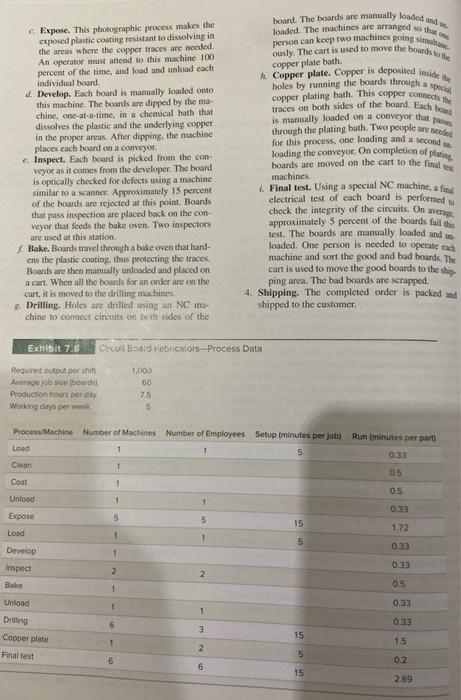

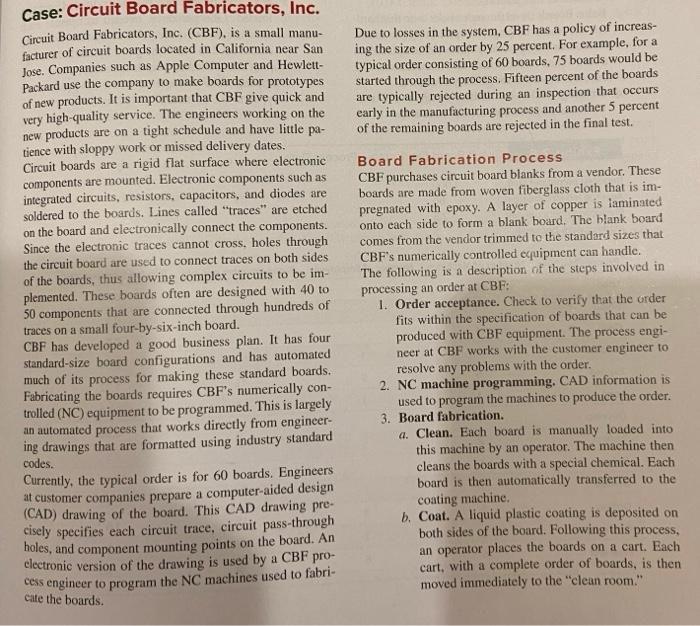

copper plate bath Expose. This photographic process makes the exposed plastic coating resistant to dissolving in the areas where the copper traces are needed An operator must attend to this machine 100 percent of the time, and load and unload each individual board Develop. Each board is manually loaded onto this machine. The boards are dipped by the ma chine, one-at-a-time, in a chemical bath that dissolves the plastic and the underlying copper in the proper areas. After dipping, the machine places cach board on a conveyor c Inspect. Each board is picked from the con veyor as it comes from the developer The board is optically checked for defects using a machine similar to a scanner, Approximately 15 percent of the boards are rejected at this point Boards that pass inspection are placed back on the con veyor that feeds the bake oven. Two inspectors are used at this station 4. Bake Boards travel through a bake oven that hund- ens the plastic coating, thus protecting the traces Boards are then manually unloaded and placed on a cart. When all the boards for an order are on the cirt, it is moved to the drilling machines e Drilling. Holes are drilled using an NC ma- chine to connect circuits on beh sides of the board. The boards are manually loaded and loaded. The machines are arranged so that person can keep two machines going Ously. The cart is used to move the boards to the . Copper plate. Copper is deposited inwide boles by running the boards through a special Copper plating bath. This copper connects the traces on both sides of the board. Each be is manually loaded on a Conveyor that through the plating bath. Two people are model for this process, one loading and a second loading the conveyor. On completion of plan boards are moved on the cart to the final te machines. 1. Final test. Using a special NC machine, afin electrical test of each board is performed check the integrity of the circuits. On average, approximately 5 percent of the boards fuil he test. The boards are manually loaded and loaded. One person is needed to operate each machine and sort the good and bad boards. The cart is used to move the good boards to the ship ping area. The bad boards are scrapped. 4. Shipping. The completed order is packed and shipped to the customer Exhibit 78 Chrust Bonio Fabricators-Process Data 1.000 60 Required output per shit Average job sie bar Production bours per day Working days per week 75 Process Machine Number of Machines Number of Employees Setup (minutes per job) Run minutes per part Load 1 5 033 Clean 1 05 Coat 1 0,5 Unload 1 0.33 Expose 5 5 15 1,22 Load 1 1 5 0.33 Develop 1 Inspect 033 2 2 Boko 0.5 1 Unload 0.33 1 1 Delling 0.33 3 Copper plate 15 1.5 2 Finaltest 5 6 0.2 6. 15 2.69 The plant was designed to run 1,000 boards per day when running five days a week and one eight-hour shift per day. Unfortunately, to date , it has not come near that capacity, and on a good day it is able to produce only about 700 boards. Data concerning the standard setup and run times for the fabrication process are given in Exhibit 7.8. These times include allowances for morn- ing and afternoon breaks, but do not include time for the half-hour lunch period. In addition, data on current staff- ing levels also are provided. The CBF process engineer insists that the capacity at each process is sufficient to run 1,000 boards per day. In order to understand the problem, CBF hired a con- sulting company to help solve the problem. copper plate bath Expose. This photographic process makes the exposed plastic coating resistant to dissolving in the areas where the copper traces are needed An operator must attend to this machine 100 percent of the time, and load and unload each individual board Develop. Each board is manually loaded onto this machine. The boards are dipped by the ma chine, one-at-a-time, in a chemical bath that dissolves the plastic and the underlying copper in the proper areas. After dipping, the machine places cach board on a conveyor c Inspect. Each board is picked from the con veyor as it comes from the developer The board is optically checked for defects using a machine similar to a scanner, Approximately 15 percent of the boards are rejected at this point Boards that pass inspection are placed back on the con veyor that feeds the bake oven. Two inspectors are used at this station 4. Bake Boards travel through a bake oven that hund- ens the plastic coating, thus protecting the traces Boards are then manually unloaded and placed on a cart. When all the boards for an order are on the cirt, it is moved to the drilling machines e Drilling. Holes are drilled using an NC ma- chine to connect circuits on beh sides of the board. The boards are manually loaded and loaded. The machines are arranged so that person can keep two machines going Ously. The cart is used to move the boards to the . Copper plate. Copper is deposited inwide boles by running the boards through a special Copper plating bath. This copper connects the traces on both sides of the board. Each be is manually loaded on a Conveyor that through the plating bath. Two people are model for this process, one loading and a second loading the conveyor. On completion of plan boards are moved on the cart to the final te machines. 1. Final test. Using a special NC machine, afin electrical test of each board is performed check the integrity of the circuits. On average, approximately 5 percent of the boards fuil he test. The boards are manually loaded and loaded. One person is needed to operate each machine and sort the good and bad boards. The cart is used to move the good boards to the ship ping area. The bad boards are scrapped. 4. Shipping. The completed order is packed and shipped to the customer Exhibit 78 Chrust Bonio Fabricators-Process Data 1.000 60 Required output per shit Average job sie bar Production bours per day Working days per week 75 Process Machine Number of Machines Number of Employees Setup (minutes per job) Run minutes per part Load 1 5 033 Clean 1 05 Coat 1 0,5 Unload 1 0.33 Expose 5 5 15 1,22 Load 1 1 5 0.33 Develop 1 Inspect 033 2 2 Boko 0.5 1 Unload 0.33 1 1 Delling 0.33 3 Copper plate 15 1.5 2 Finaltest 5 6 0.2 6. 15 2.69 The plant was designed to run 1,000 boards per day when running five days a week and one eight-hour shift per day. Unfortunately, to date , it has not come near that capacity, and on a good day it is able to produce only about 700 boards. Data concerning the standard setup and run times for the fabrication process are given in Exhibit 7.8. These times include allowances for morn- ing and afternoon breaks, but do not include time for the half-hour lunch period. In addition, data on current staff- ing levels also are provided. The CBF process engineer insists that the capacity at each process is sufficient to run 1,000 boards per day. In order to understand the problem, CBF hired a con- sulting company to help solve the