Question: Answer the following question using the picture as reference 10.2 In Example 10.2, suppose that the vehicles operate according to the following scheduling rules: (1)

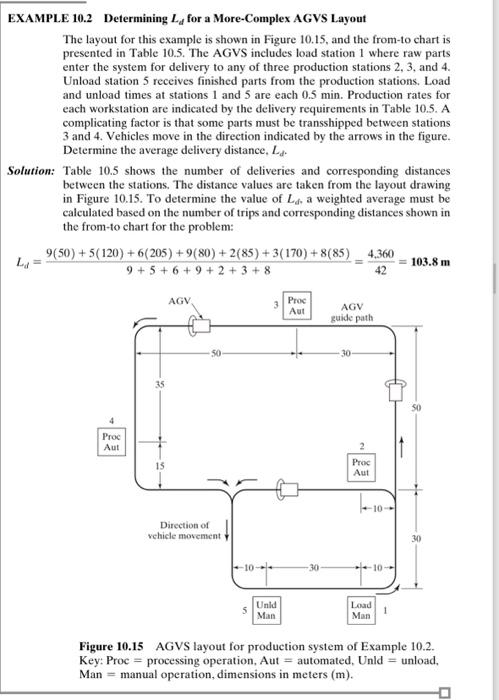

EXAMPLE 10.2 Determining Ld for a More-Complex AGVS Layout The layout for this example is shown in Figure 10.15, and the from-to chart is presented in Table 10.5. The AGVS includes load station 1 where raw parts enter the system for delivery to any of three production stations 2,3 , and 4 . Unload station 5 receives finished parts from the production stations. Load and unload times at stations 1 and 5 are each 0.5min. Production rates for each workstation are indicated by the delivery requirements in Table 10.5. A complicating factor is that some parts must be transshipped between stations 3 and 4 . Vehicles move in the direction indicated by the arrows in the figure. Determine the average delivery distance, Ld. Solution: Table 10.5 shows the number of deliveries and corresponding distances between the stations. The distance values are taken from the layout drawing in Figure 10.15. To determine the value of Ld a weighted average must be calculated based on the number of trips and corresponding distances shown in the from-to chart for the problem: Ld=9+5+6+9+2+3+89(50)+5(120)+6(205)+9(80)+2(85)+3(170)+8(85)=424.360=103.8m Figure 10.15 AGVS layout for production system of Example 10.2. Key: Proc = processing operation, Aut = automated, Unld = unload, Man = manual operation, dimensions in meters (m)

Step by Step Solution

There are 3 Steps involved in it

To solve this problem we need to address each part step by step a Determine the empty travel distances and develop a fromto chart Identify the empty t... View full answer

Get step-by-step solutions from verified subject matter experts