Question: ANSWER THE QUESTION DOWN BELOW BASED ON THE CASE STUDY Background Transport for London (TfL) is one of the functional bodies of the Greater London

ANSWER THE QUESTION DOWN BELOW BASED ON THE CASE STUDY

Background

Transport for London (TfL) is one of the functional bodies of the Greater London Authority (GLA),

responsible for delivering transport services throughout London to over 1,107 million passengers

every year. It is committed to reducing London's transport network's contribution to climate change

as part of wider ambitions to reduce London's CO2 emissions by 60% by 2025 (in comparison to 1990

levels).

The London Underground is perhaps the most famous part of London's public transit network, with

11 lines serving 270 stations. The fluorescent lighting technologies traditionally used to light these

stations represented a significant maintenance cost, and in 2015 TfL sought to reduce whole life-

cycle costs (WLC) by finding a range of new lighting solutions and products.

With support from the EU-funded Procurement of Lighting Innovation and Technology in Europe

(PRO-LITE) project, TfL introduced a new WLC and performance based process for lighting. The

process has been met with such success that it will now be applied to a range of other assets

commonly found across London's transport network.

Procurement Approach

PRO-LITE pre-procurement process

Tf is the lead partner of the PRO-LITE project, coordinating five other partners and two associate

partners across five European Member States.

In 2014, the PRO-LITE project partners implemented a novel Early Market Engagement strategy with

the aim of driving competition and stimulating innovation within the lighting market across Europe.

This approach was based on a Market Sounding Prospectus and included presenting at Europe's

largest lighting conferences, developing and using online submission tools, and distributing market

surveys to gather information on manufacturers' capabilities, innovative technologies, as well as

their experiences working with others to innovate. TfL also hosted a 'Suppliers Morning' event at

which over 70 manufacturers, suppliers and representatives from Europe's Lighting Industry

Association were in attendance. The event helped TfL acquire information on almost 300 different

innovative lighting technologies.

The expertise gathered through the early market engagement exercise was used to inform the

procurement processes employed, and in particular, the development of the performance based

technical specifications and procurement documents used for tendering.

In addition, the business case (for TfL) examined how WLCs can differ for the same product installed

in different locations across the Underground network (such as above escalators, on subway

platforms, in high and low access areas and at the back of house). This analysis was used to indicate

where the greatest value from an investment in a new technology could be achieved.

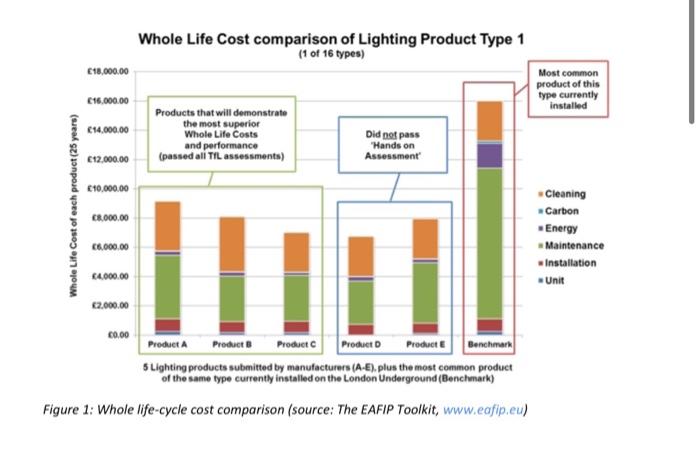

Using the WLC analysis of products allowed TfL to consider a range of information beyond unit price,

including installation, maintenance, energy use,

carbon, and cleaning costs. This approach demonstrated that the biggest savings were not from short-term material costs, or to a greater

extent energy costs, but from longer term labor costs (including cleaning, installation and

maintenance).

The calculation of WLC led to a massive increase in confidence among the TfL management to invest

in innovative solutions, as the long-term savings outweighed any additional upfront costs of LED

solutions, generating total cost savings of up to 50% (see figure below).

The business case also proved that the upfront investment risk could be mitigated by first installing

new LED lighting above escalators and high access areas, where the payback time was shortest and

return on investment high, allowing savings to be released to install LEDs in other parts of the

London Underground network.

Criteria used in the procurement process

Following extensive market engagement, the procurement process was split into three stages to

ensure all relevant risks were mitigated:

Stage one: Pre-qualification stage to sound out market interest and ensure manufacturers

understood TfL's requirements as a transport operator.

Stage two: Following the results of stage one, invitations to tender were sent out to a narrowed

group of manufacturers based on their ability to meet TfL's requirements at stage one. During this

stage, manufacturers provided technical information on their products to enable TfL to undertake a

WLC comparison of the technologies on offer. The products with the highest scores (those with the

best environment performance) were invited to stage three of the process.

Stage three: Manufacturers successful in stage two submitted samples for In Situ ('hands-on') testing

in order to validate their technical claims and the WLC modelling. Many were the same as the 'paper'

description received at stage two, however some were very different and were rejected as a result

(as shown in Figure 1, above). The hands-on assessment was the 'final filter', and gave those who will

maintain the products on a day-to-day basis (the engineers) an opportunity to input into the process.

Technical specifications

Following a comprehensive consultation process with over 80 lighting manufacturers and suppliers in

addition to a robust internal review, TfL prepared technical specifications for the procurement of

more advanced lighting technologies. These outlined the minimum requirements acceptable for

lighting products, and were provided for both a range of 'luminaires' and 'lamps'.

Requirements on the physical construction of luminaires stated that they should be modular in

design so that components could be readily replaceable upon failure, become life expired or

redundant. In addition, the specifications for both luminaires and lamps stated that they should be

designed to maintain their International Protection (IP) rating throughout their life cycle, without

degrading due to maintenance and periodic testing. The technical specifications for both lamps and

luminaires also included a number of reliability requirements - such as:

The Abrupt Failure Value (AFV) of the lamp at 50,000 hours shall be less than or equal to 10%

A failure fraction B50 (products' rated average life) or 50% shall be used for all lumen

maintenance values reported

All lumen maintenance values shall be given in respect to L70 (that is, the tested LEDs

produce 70% of the initial light output)

The lamp should provide a minimum of 50,000 hours of L70 performance verified by

demonstrating to a 90% level of confidence that the 50,000 hour success probability is 0.5 or

50% when subjected to a maximum operating temperature of 50C and mean operating

current

The lamp should provide 6,000 hours of L90 performance verified by demonstrating to a 90%

level of confidence that the 6,000 hour success probability is 0.9 or 90% when subjected to a

maximum operating temperature of 50C and mean operating current

Revisions were also made to the London Underground Lighting Standard (S1066) which states

upfront that lighting systems shall be: safe; enable the effective performance of all necessary tasks

by both passengers and staff; meet the requirements of the visually and sensory impaired; provide a

welcoming visual environment; designed to minimise energy use; and have an optimised design to

minimise WLC. Under environmental considerations, among other parameters, it emphasises that all lighting products used in the London Underground are subject to the Waste Electrical and Electronic

Equipment Directive (WEEE), and that lamps and luminaries shall be recycled where suitable product

recycling schemes exist. Furthermore, it was required that the lighting system be assembled from

system elements selected to optimise WLC. The WLC analysis for the lighting system assumed:

25 years operation

Discount factor of 3.5%

Electricity cost rate of f0.10 (approximately 0.12) per kWh

490g of CO, emitted per kWh of electricity used to power the system (based on 2014

emissions factors)

CO, valued at 3 (approximately 3.52) per tonne (based on the 2014 rate) increasing at 2%

compounded

Award criteria

In the third In Situ testing phase of the procurement process, products with appropriate WLCs which

met TfL's standards were then assessed against the following criteria:

Robustness and durability

D.

Ease of access to components

Ease to dismantle

d. Ease to reassemble

Integrity after reassembly

Ease to replace parts/components

&.

Ease to clean

Ease to install

Ease to remove/uninstall

Ability to accommodate wiring

Ease to switch on and off

The assessment was made following a number of different standards: national, EU, international, and

specific to TfL, such as the S1066 developed for the London Underground. All standards existed prior

to PRO-LITE, however were revised to ensure they drove the intended behaviour in the lighting

market, for fL's purposes. In total, manufacturers submitted just over 25,000 (approximately

29,500) worth of products for TfL's maintenance teams to assess

Contract performance clauses

The contract contains a 'product refresh' clause that incentivises manufacturers to continue to

innovate and produce products that will reduce TfL's WLCs and impact on the environment.

Results

The rail industry is naturally risk averse, with passenger safety being their top priority; by undertaking

a thorough pre- procurement process of research and engagement with the market, TfL was able to

develop a high level of confidence in innovative technologies, and in June 2016 awarded a framework

contract worth 8 million (10 million) for the long-term supply of LEDs for use across the London

Underground network. Over 50 suppliers responded to the pre-qualification stage. Invitations to

tender were then sent to 30 suppliers for over 170 products. In the final stage, samples of 120

products were requested for the In Situ assessment.

In June 2016, eight year long contracts were awarded to 13 manufacturers to supply 45 products.

These products fulfil the vast majority of TfL's lighting requirements, and are mandated for use

across the London Underground. The contracts were awarded to a sufficient number

manufacturers to ensure that they continue to compete within the contract to reduce TfL's WLC. The

more manufacturers improve their products, the more likely it is that TfL will order them in future.

Manufacturers are aware that other options are available if they 'drop' their standards, hence are

incentivised to continue to innovate in the interest of TfL and the environment. Furthermore, there

are currently well over 500 different lighting products installed across the London Underground.

Through the contracts put in place the London Underground will be able to reduce this number by

approximately 90% (to 45-50)

- creating economies of scale (tor TL) and the successtul

manufacturers.

As an indicative result of this procurement process, savings have been calculated for the ticket hall of

the London Underground Charing Cross Station, where a like-for-like replacement of current

technology with the products identified through the PRO- LITE process will save 25% in WLC,

including 75% on maintenance costs.

In terms of timeframes, TfL estimate that the process will take less than a year now they understand

the level of information they need to gather and how to effectively communicate requirements to

the market place.

Furthermore, regarding financial support, the PRO-LITE project was supported by a grant of two

million euro, and was co-ordinated by TfL. Approximately one quarter of the grant was used by TfL.

The financial support from the European Commission allowed TfL to recruit the expert resources, in

terms of personnel, to undertake the design work required to demonstrate how TfL can use its

procurement power to drive innovation.

Environmental impacts

Reducing maintenance costs was the primary concern for TfL during the development of the PRO-

LITE project. As LED technologies generally last longer - requiring fewer maintenance interventions and are more energy efficient than fluorescent technologies, TfL was able to build a robust business

case to invest in a technology that makes good business sense as well as being good for the

environment.

Over 90% of the environmental impact from the use of lamps in lighting comes from the use phase,

from energy consumption and associated greenhouse gas emissions while the light is being used. The

environmental effect of energy consumption originates from the power generation, where fossil

energy carriers like oil, natural gas or coal are converted into electricity (source: Green Public

Procurement, Indoor Lighting - Technical Background Report. European Commission (2011), page

13).

Lessons learned and future challenges

Identify and where possible quantify the potential benefits, including non-environmental

benefits in order to create a multi-dimensional business case.

Identify and engage all relevant stakeholders, understand their issues and ensure that their

issues or concerns are addressed as part of the solution identified.

Do not be afraid to engage the market early. The industry usually has information that can be

used to strengthen your business case.

Cast the net far and wide. Engage as many manufacturers and suppliers as possible and

encourage as much competition in the market as possible.

Consolidate your spend. Manufacturers are more likely to innovate if the prize for winning

the contract is big.

Q2 2. How did they manage the environmental impacts

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock