Question: Assignment 1: TADT 3700 Operations Planning and Control 1- Read the material on d21: Master Scheduling & Capacity Management. Answer the following questions using excel

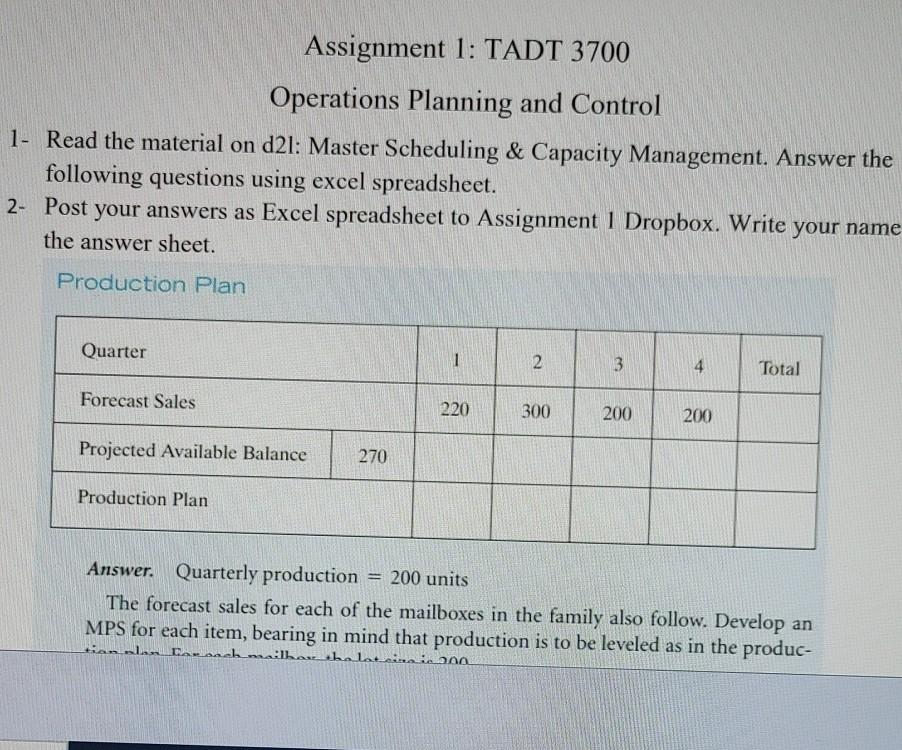

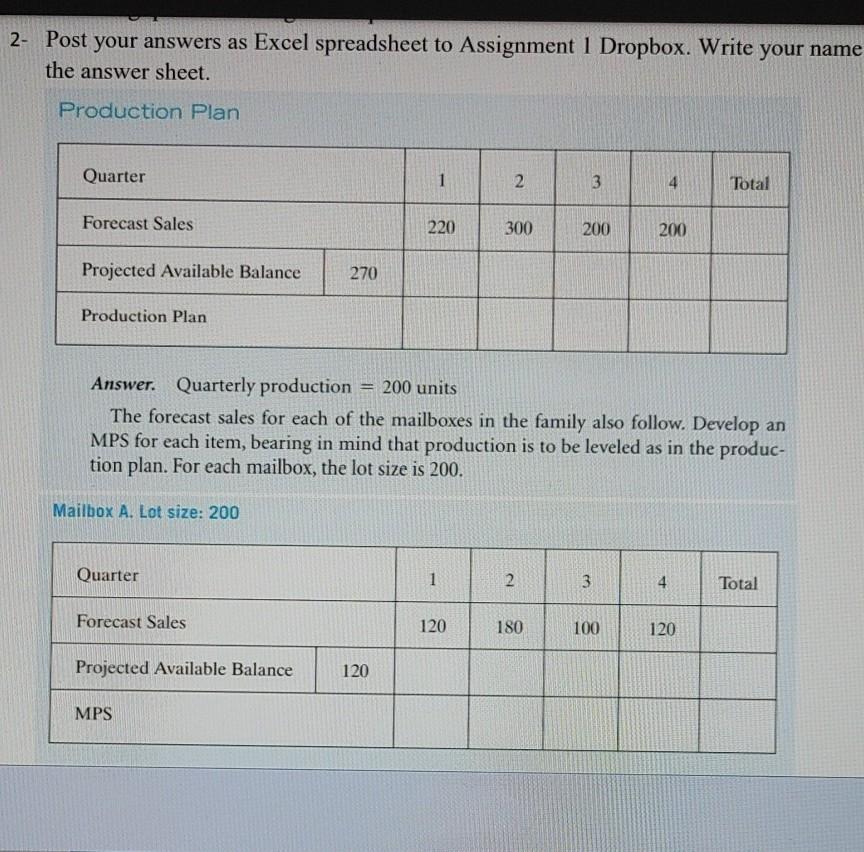

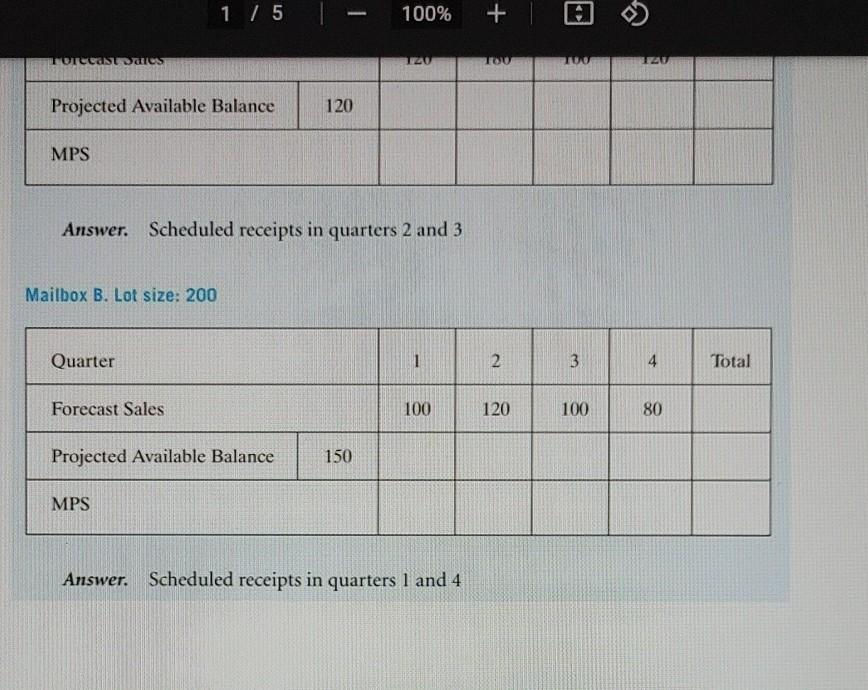

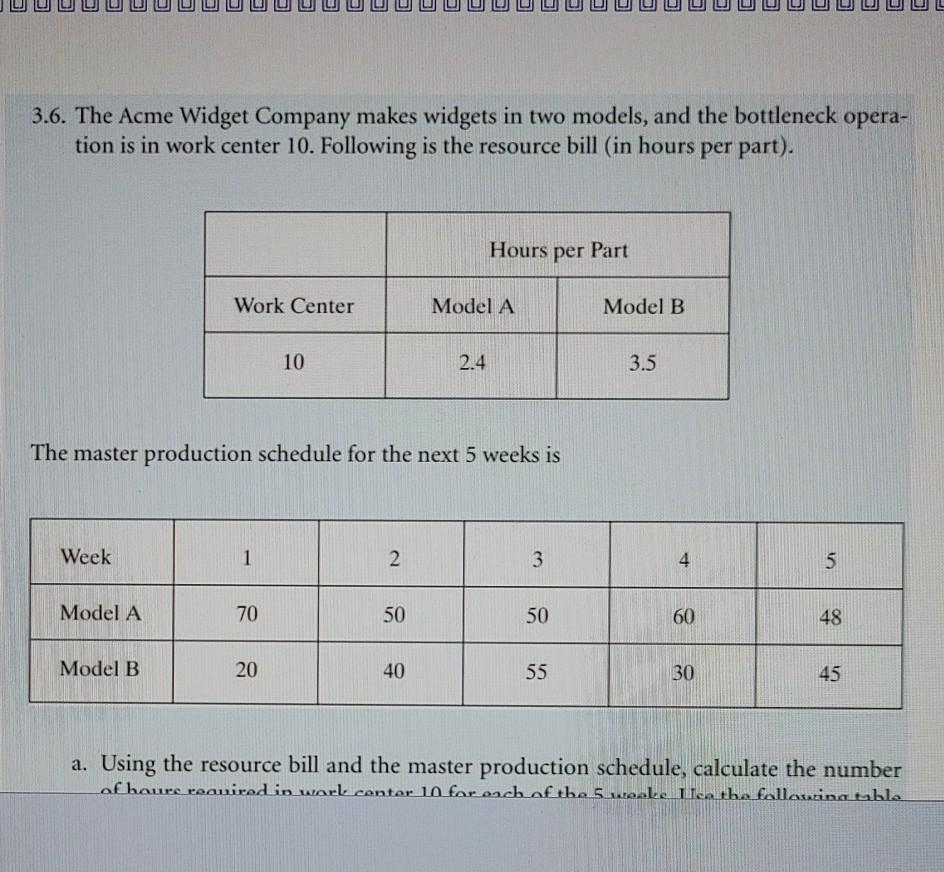

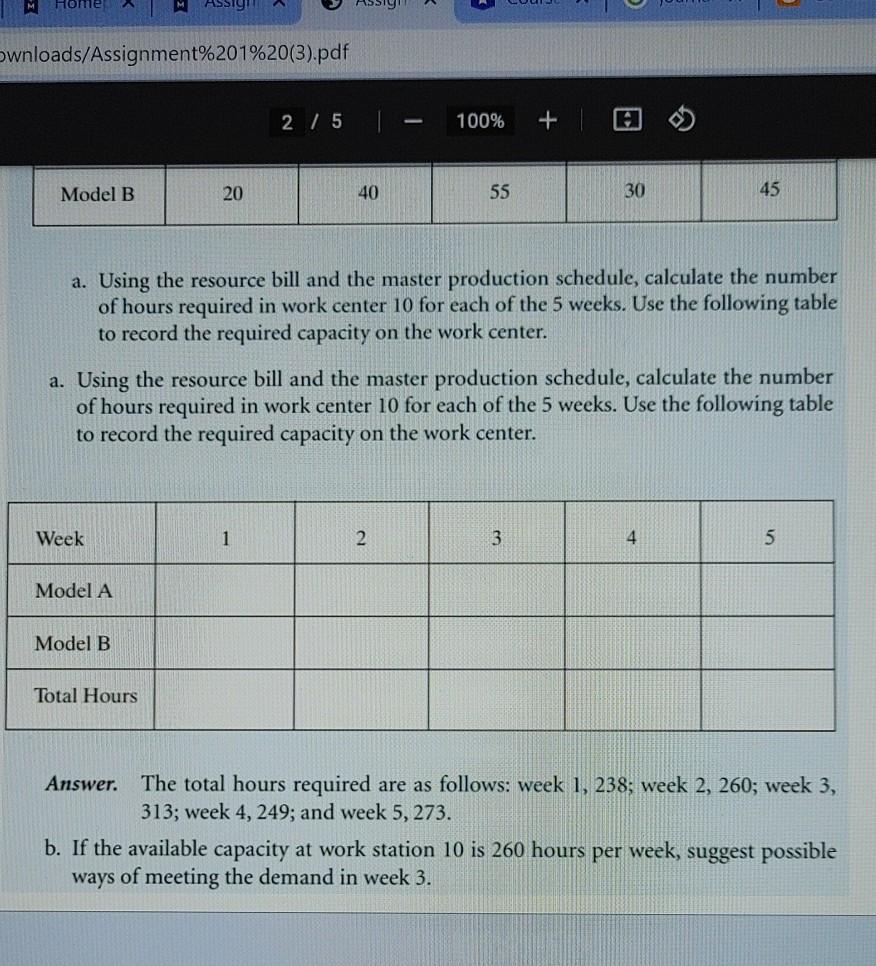

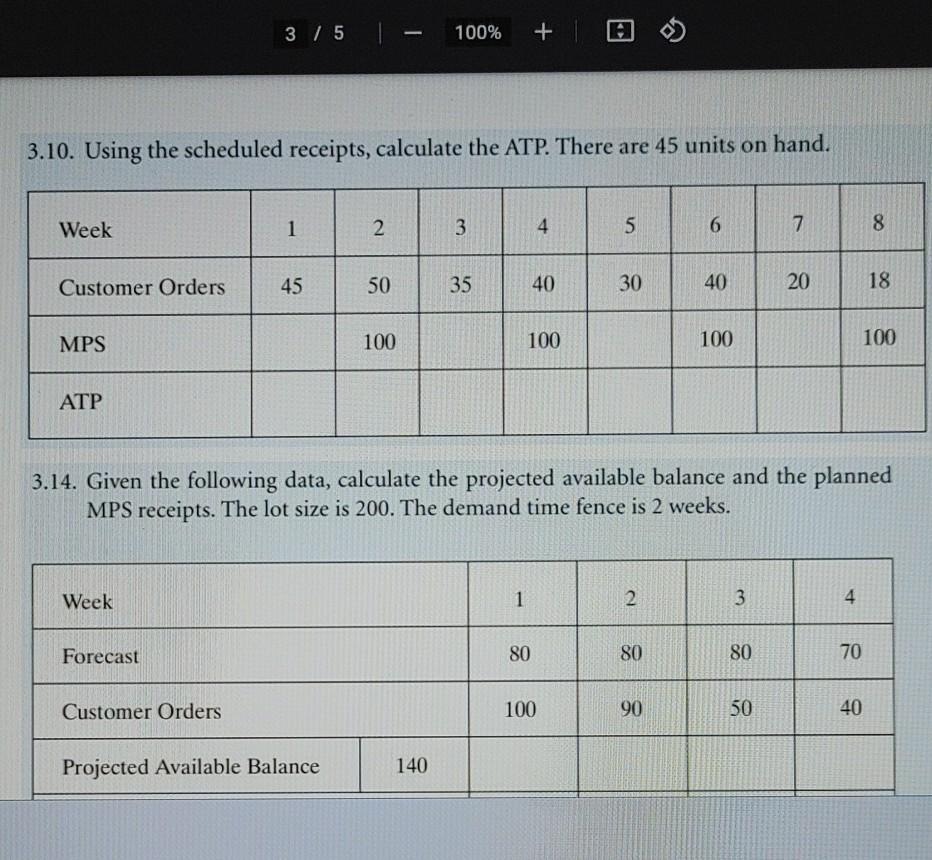

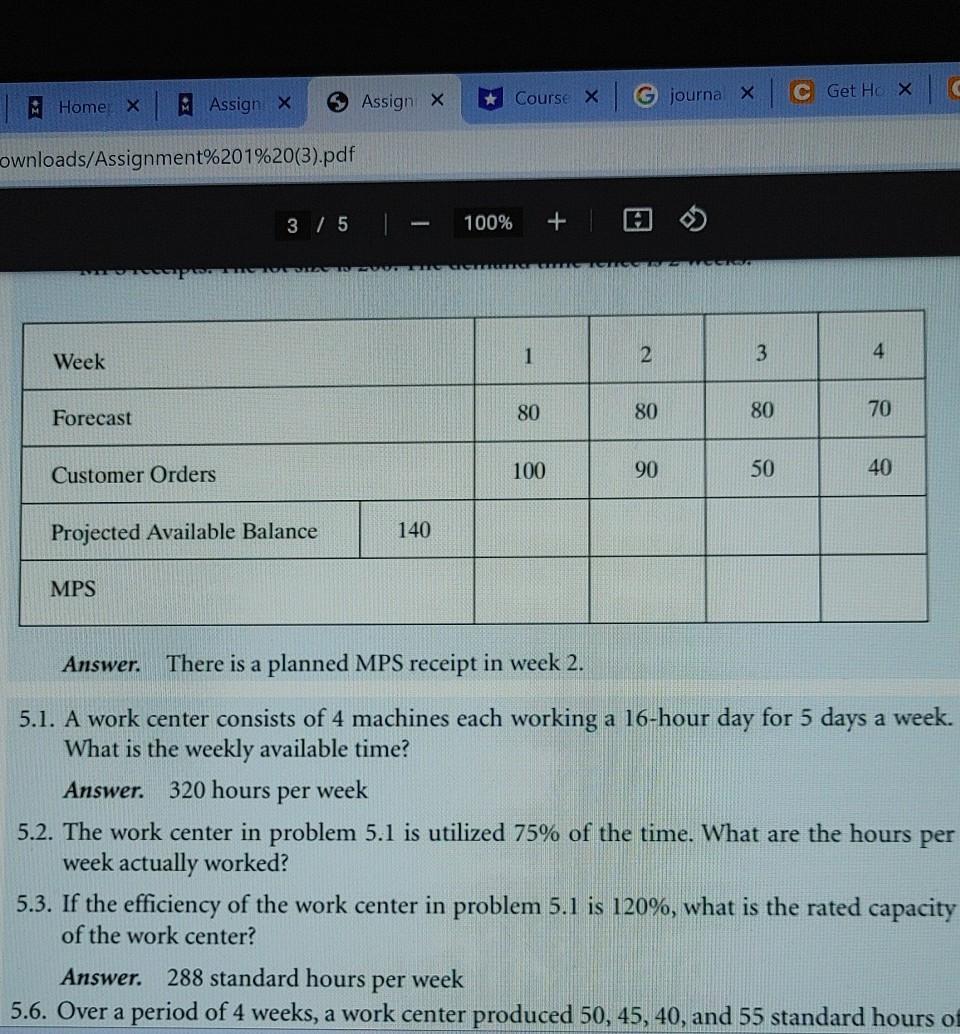

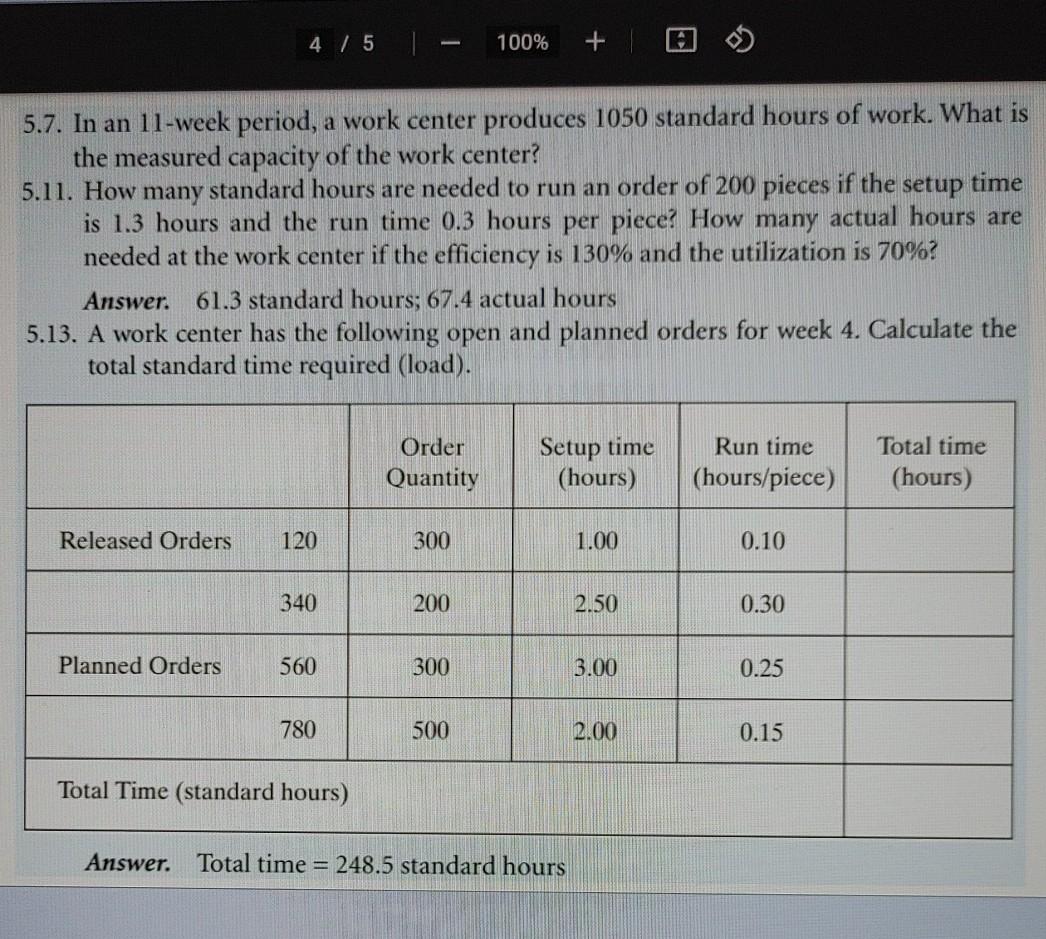

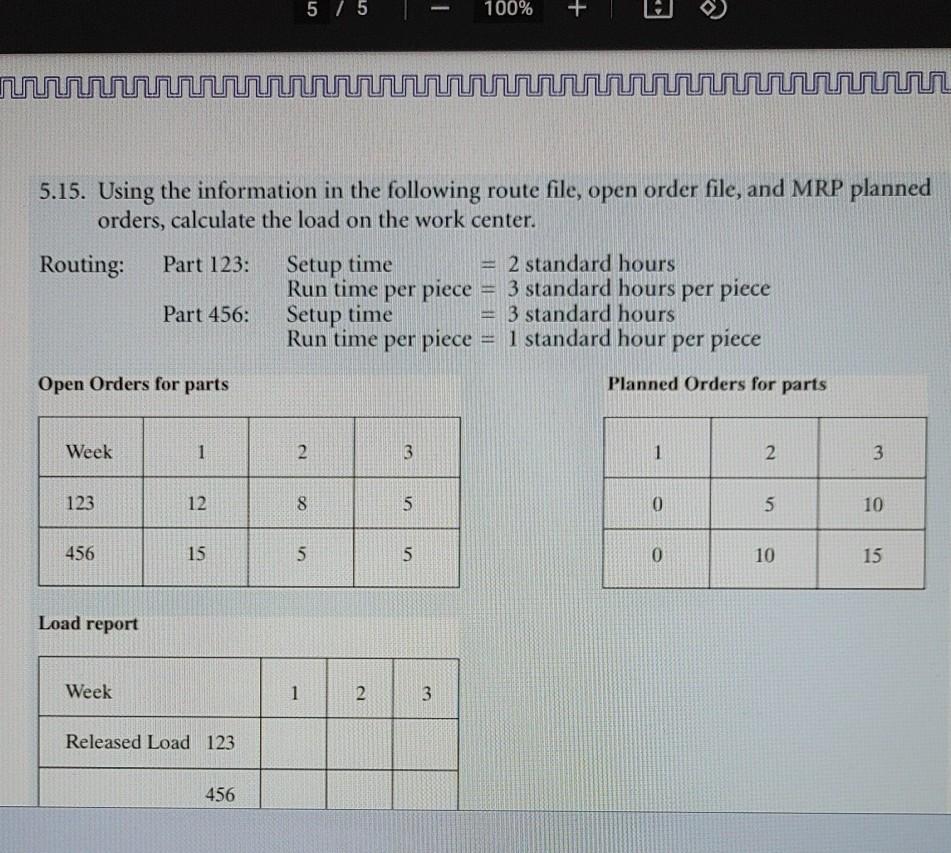

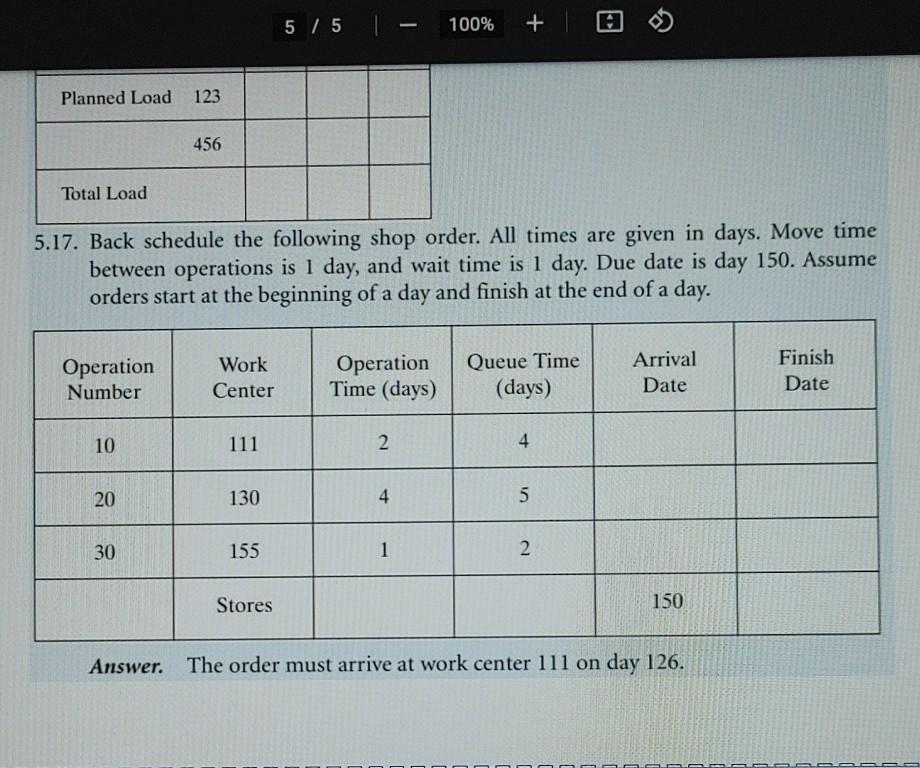

Assignment 1: TADT 3700 Operations Planning and Control 1- Read the material on d21: Master Scheduling & Capacity Management. Answer the following questions using excel spreadsheet. 2- Post your answers as Excel spreadsheet to Assignment 1 Dropbox. Write your name the answer sheet. Production Plan Quarter 1 2 3 Total Forecast Sales 220 300 200 200 Projected Available Balance 270 Production Plan Answer. Quarterly production 200 units The forecast sales for each of the mailboxes in the family also follow. Develop an MPS for each item, bearing in mind that production is to be leveled as in the produc- trannlan tasach mailbox balat nn 2- Post your answers as Excel spreadsheet to Assignment 1 Dropbox. Write your name the answer sheet. Production Plan Quarter 1 1 2 3 Total Forecast Sales 220 300 200 200 Projected Available Balance 270 Production Plan Answer. Quarterly production = 200 units The forecast sales for each of the mailboxes in the family also follow. Develop an MPS for each item, bearing in mind that production is to be leveled as in the produc- tion plan. For each mailbox, the lot size is 200. Mailbox A. Lot size: 200 Quarter 1 2 2 3 4 Total Forecast Sales 120 180 100 120 Projected Available Balance 120 MPS 1 / 5 100% + TOTCCASI DUTOS 12U TOU Projected Available Balance 120 MPS Answer. Scheduled receipts in quarters 2 and 3 Mailbox B. Lot size: 200 Quarter 1 2 3 4 Total Forecast Sales 100 120 100 80 Projected Available Balance 150 MPS Answer. Scheduled receipts in quarters 1 and 4 3.6. The Acme Widget Company makes widgets in two models, and the bottleneck opera- tion is in work center 10. Following is the resource bill (in hours per part). Hours per Part Work Center Model A Model B 10 2.4 3.5 The master production schedule for the next 5 weeks is Week 1 2 3 4 5 Model A 70 50 50 60 48 Model B 20 40 55 30 45 a. Using the resource bill and the master production schedule, calculate the number of houre required in work contor 10 for ouch of the 5 woole Leathe following thlo Home ma wnloads/Assignment%201%20(3).pdf 2 / 5 100% + Model B 20 40 55 30 45 a. Using the resource bill and the master production schedule, calculate the number of hours required in work center 10 for each of the 5 weeks. Use the following table to record the required capacity on the work center. a. Using the resource bill and the master production schedule, calculate the number of hours required in work center 10 for each of the 5 weeks. Use the following table to record the required capacity on the work center. Week 1 2 3 4 5 Model A Model B Total Hours Answer. The total hours required are as follows: week 1, 238; week 2, 260; week 3, 313; week 4, 249; and week 5, 273. b. If the available capacity at work station 10 is 260 hours per week, suggest possible ways of meeting the demand in week 3. 3 / 5 100% + 3.10. Using the scheduled receipts, calculate the ATP. There are 45 units on hand. Week - 1 2 3 4 5 6 7 8 Customer Orders 45 50 35 40 30 40 20 18 MPS 100 100 100 100 ATP 3.14. Given the following data, calculate the projected available balance and the planned MPS receipts. The lot size is 200. The demand time fence is 2 weeks. Week 1 2 3 4 Forecast 80 80 80 70 Customer Orders 100 90 50 40 Projected Available Balance 140 C Home x C Get Hox Assign x $ Assign X * Course X Gjourna X ownloads/Assignment%201%20(3).pdf 3 / 5 100% + * 1 Week 2 3 4 80 Forecast 80 80 70 Customer Orders 100 90 50 40 Projected Available Balance 140 MPS Answer. There is a planned MPS receipt in week 2. 5.1. A work center consists of 4 machines each working a 16-hour day for 5 days a week. What is the weekly available time? Answer. 320 hours per week 5.2. The work center in problem 5.1 is utilized 75% of the time. What are the hours per week actually worked? 5.3. If the efficiency of the work center in problem 5.1 is 120%, what is the rated capacity of the work center? Answer. 288 standard hours per week 5.6. Over a period of 4 weeks, a work center produced 50, 45, 40, and 55 standard hours of 4 / 5 100% + 5.7. In an 11-week period, a work center produces 1050 standard hours of work. What is the measured capacity of the work center? 5.11. How many standard hours are needed to run an order of 200 pieces if the setup time is 1.3 hours and the run time 0.3 hours per piece? How many actual hours are needed at the work center if the efficiency is 130% and the utilization is 70%? Answer. 61.3 standard hours; 67.4 actual hours 5.13. A work center has the following open and planned orders for week 4. Calculate the total standard time required (load). Order Quantity Setup time (hours) Run time (hours/piece) Total time (hours) Released Orders 120 300 1.00 0.10 340 200 2.50 0.30 Planned Orders 560 300 3.00 0.25 780 500 2.00 0.15 Total Time (standard hours) Answer. Total time = 248.5 standard hours 5 / 5 100% + UUUUUUUUUUUUUUUUUUUUU un 5.15. Using the information in the following route file, open order file, and MRP planned orders, calculate the load on the work center. Routing: Part 123: Setup time = 2 standard hours Run time per piece = 3 standard hours per piece Setup time 3 standard hours Run time per piece 1 standard hour per piece Part 456: Open Orders for parts Planned Orders for parts Week 1 10 2 3 1 2 3 123 12 8 8 5 0 5 10 5 5 456 15 5 0 10 15 Load report Week 1 1 2 3 Released Load 123 456 5 / 5 | - 100% + Planned Load 123 456 Total Load 5.17. Back schedule the following shop order. All times are given in days. Move time between operations is 1 day, and wait time is 1 day. Due date is day 150. Assume orders start at the beginning of a day and finish at the end of a day. Work Operation Number Operation Time (days) Queue Time (days) Arrival Date Finish Date Center 10 111 2 4 20 130 4 5 5 30 155 1 2 Stores 150 Answer. The order must arrive at work center 111 on day 126. AU

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock