Question: Asst 3 MRP Calculation 10.1 Material Requirements Planning Exercise Assignment Learning Objective: The purpose of this exercise is to demonstrate the materials requirement planning (MRP)

Asst 3 MRP Calculation 10.1 Material Requirements Planning Exercise Assignment Learning Objective: The purpose of this exercise is to demonstrate the materials requirement planning (MRP) functionality in SAP system. As a first step, a small test problem with five materials in a BOM is solved manually to determine planned order releases by carrying out MRP calculations. The problem is solved in a traditional way with weekly time buckets.

The main steps in this exercise are outlined below.

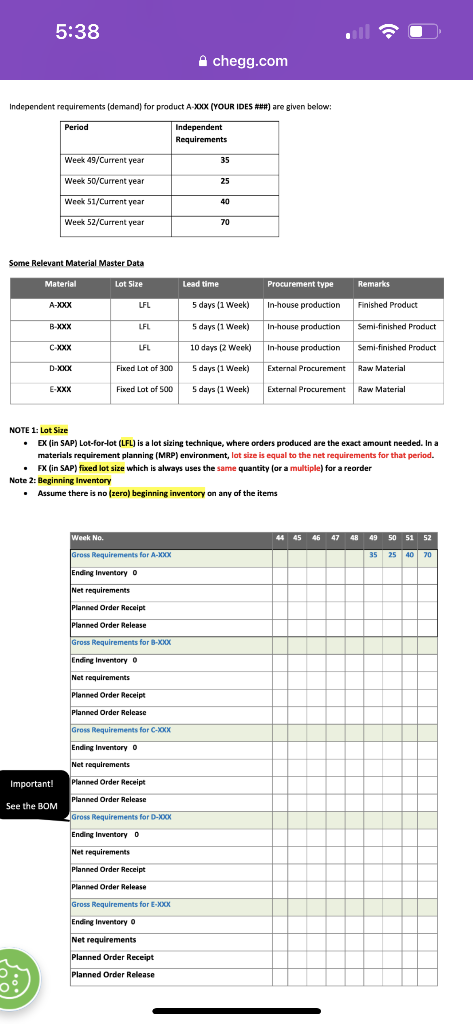

Calculate Planned Order Releases for materials A-XXX (YOUR IDES ###), B-XXX (YOUR IDES ###), C-XXX (YOUR IDES ###), D-XXX (YOUR IDES ###), and E-XXX (YOUR LEARN-###). Relevant data on independent requirements (forecast), BOM, and material master data are given below.

The BOM for product A-XXX is shown below. One piece of D-XXX and two pieces of E-XXX are assembled to make one unit of C-XXX. Two pieces of C-XXX and one piece of D-XXX are needed to make one subassembly of B-XXX. of B-XXX are further assembled to make one unit of the product A-XXX.

further question in Screenshot. Please solve this question only dont give any other answer.

Independent requirements [demand) for product A-XCXX (YOUR IDES wH] are given below: Some Relevant Material Master Data NOTE 1: Lat Size - EX (in SAP) Lot-for-lot (LFL) is a lot sizing technique, where orders produced are the exact amount needed. In a materials requirement planning (MRP) emvironment, lot size is equal to the net requirements for that period. - FX (in SAP) fixed lot size which is always uses the same quantity (or a multiple) for a reorder Nate 2: Beginning Inwentory - Assume there is no (zero) beginning inventory on any of the items Independent requirements [demand) for product A-XCXX (YOUR IDES wH] are given below: Some Relevant Material Master Data NOTE 1: Lat Size - EX (in SAP) Lot-for-lot (LFL) is a lot sizing technique, where orders produced are the exact amount needed. In a materials requirement planning (MRP) emvironment, lot size is equal to the net requirements for that period. - FX (in SAP) fixed lot size which is always uses the same quantity (or a multiple) for a reorder Nate 2: Beginning Inwentory - Assume there is no (zero) beginning inventory on any of the items

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts