Question: Assume that lead time is zero for Leg assembly and Back assembly . (Hint: If the lead time is zero, then planned order receipt equals

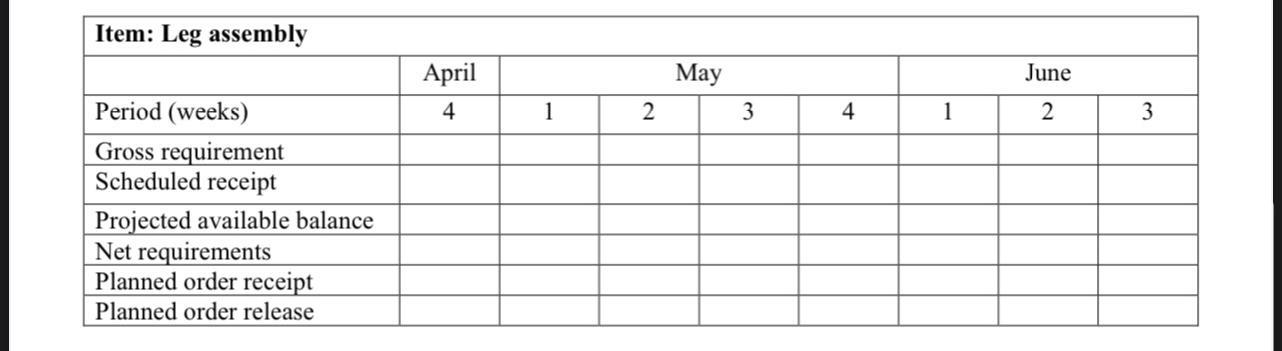

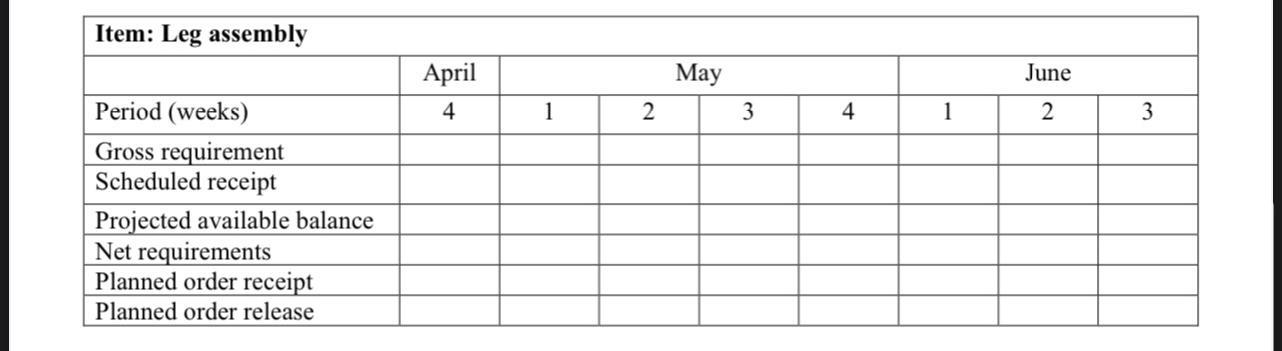

Assume that lead time is zero for "Leg assembly" and "Back assembly ". (Hint: If the lead time is zero, then planned order receipt equals planned order release in each week.) There are no quantity-on-hand and scheduled receipts for both. The lot sizing policy is "lot for lot" for both.

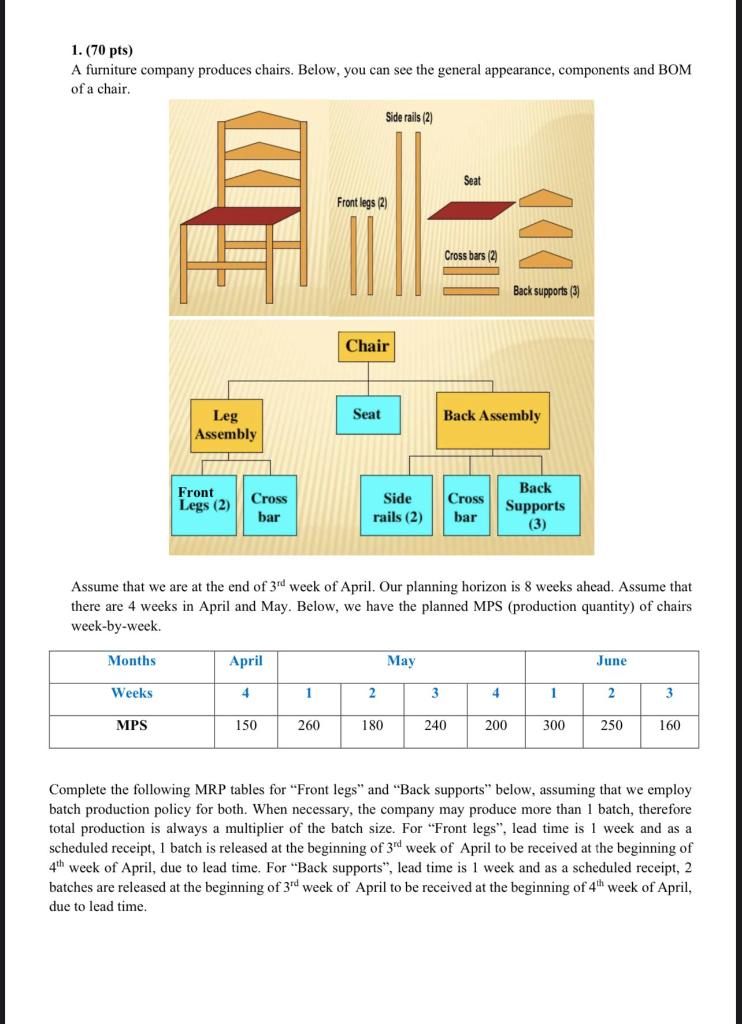

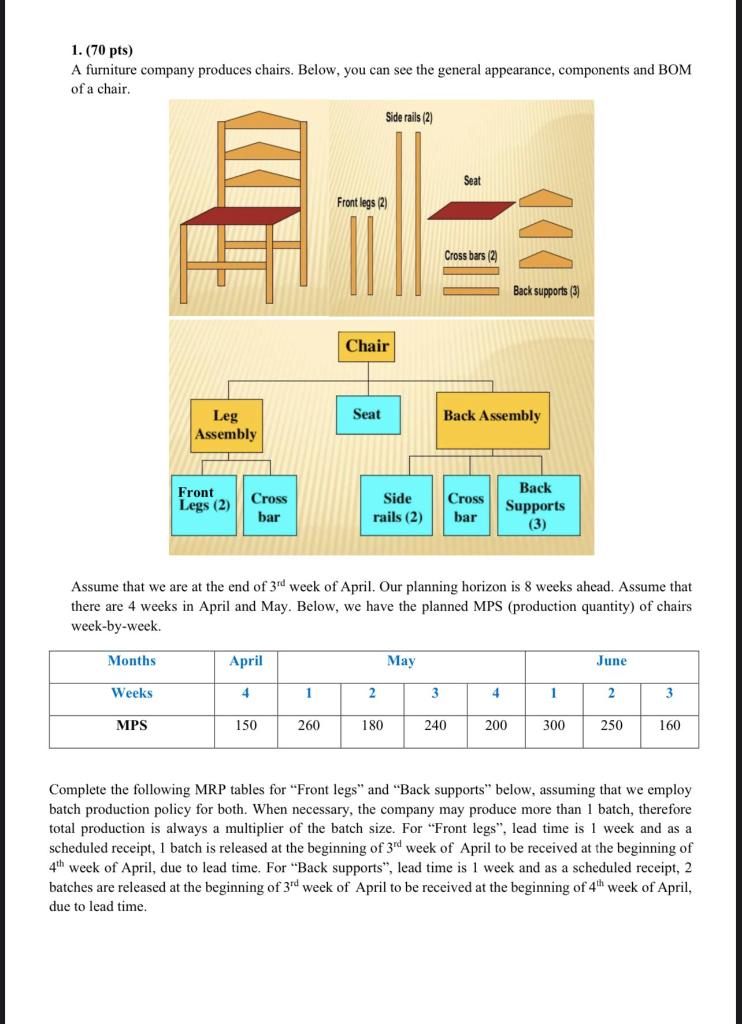

1. (70 pts) A furniture company produces chairs. Below, you can see the general appearance, components and BOM of a chair. Side rails (2) Seat Front legs (2) Cross bars (2) Back supports (3) Chair Seat Back Assembly Leg Assembly Front Cross Legs (2) Cross bar Side rails (2) Back Supports (3) bar Assume that we are at the end of 3rd week of April. Our planning horizon is 8 weeks ahead. Assume that there are 4 weeks in April and May. Below, we have the planned MPS (production quantity) of chairs week-by-week. Months April May June Weeks 4 1 2 3 4 1 2 3 MPS 150 260 180 240 200 300 250 160 Complete the following MRP tables for "Front legs" and "Back supports" below, assuming that we employ batch production policy for both. When necessary, the company may produce more than 1 batch, therefore total production is always a multiplier of the batch size. For "Front legs", lead time is 1 week and as a scheduled receipt, 1 batch is released at the beginning of 3rd week of April to be received at the beginning of 4th week of April, due to lead time. For "Back supports, lead time is 1 week and as a scheduled receipt, 2 batches are released at the beginning of 3rd week of April to be received at the beginning of 4th week of April, due to lead time. Item: Leg assembly May June April 4 1 2 3 4 1 2 3 Period (weeks) Gross requirement Scheduled receipt Projected available balance Net requirements Planned order receipt Planned order release 1. (70 pts) A furniture company produces chairs. Below, you can see the general appearance, components and BOM of a chair. Side rails (2) Seat Front legs (2) Cross bars (2) Back supports (3) Chair Seat Back Assembly Leg Assembly Front Cross Legs (2) Cross bar Side rails (2) Back Supports (3) bar Assume that we are at the end of 3rd week of April. Our planning horizon is 8 weeks ahead. Assume that there are 4 weeks in April and May. Below, we have the planned MPS (production quantity) of chairs week-by-week. Months April May June Weeks 4 1 2 3 4 1 2 3 MPS 150 260 180 240 200 300 250 160 Complete the following MRP tables for "Front legs" and "Back supports" below, assuming that we employ batch production policy for both. When necessary, the company may produce more than 1 batch, therefore total production is always a multiplier of the batch size. For "Front legs", lead time is 1 week and as a scheduled receipt, 1 batch is released at the beginning of 3rd week of April to be received at the beginning of 4th week of April, due to lead time. For "Back supports, lead time is 1 week and as a scheduled receipt, 2 batches are released at the beginning of 3rd week of April to be received at the beginning of 4th week of April, due to lead time. Item: Leg assembly May June April 4 1 2 3 4 1 2 3 Period (weeks) Gross requirement Scheduled receipt Projected available balance Net requirements Planned order receipt Planned order release