Question: based on the information given in the case study and the analysis of the data , can you identify any major problems ib the procurement

based on the information given in the case study and the analysis of the data , can you identify any major problems ib the procurement operations of ART

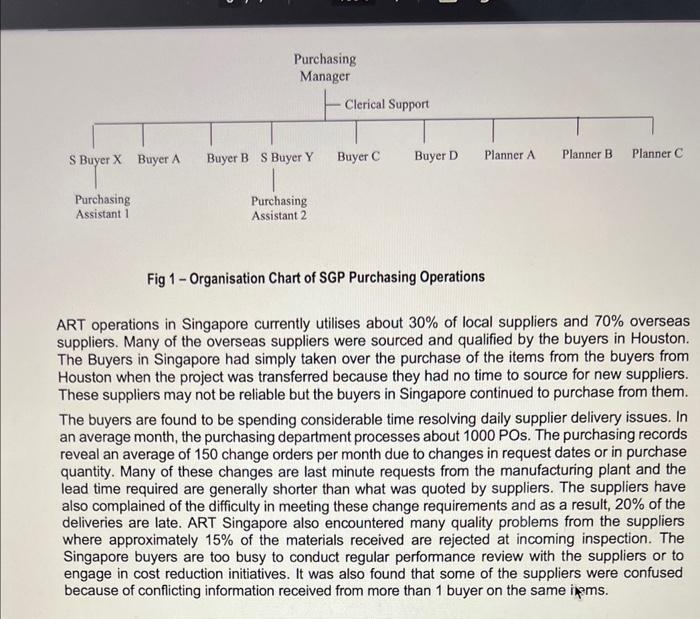

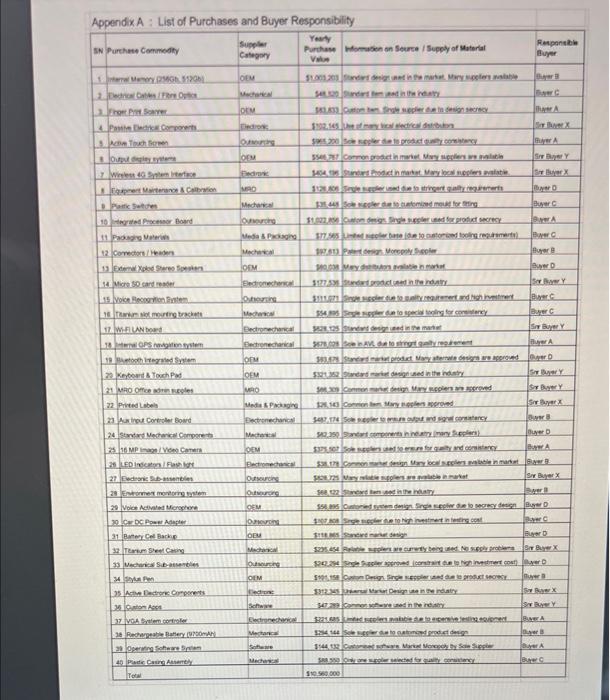

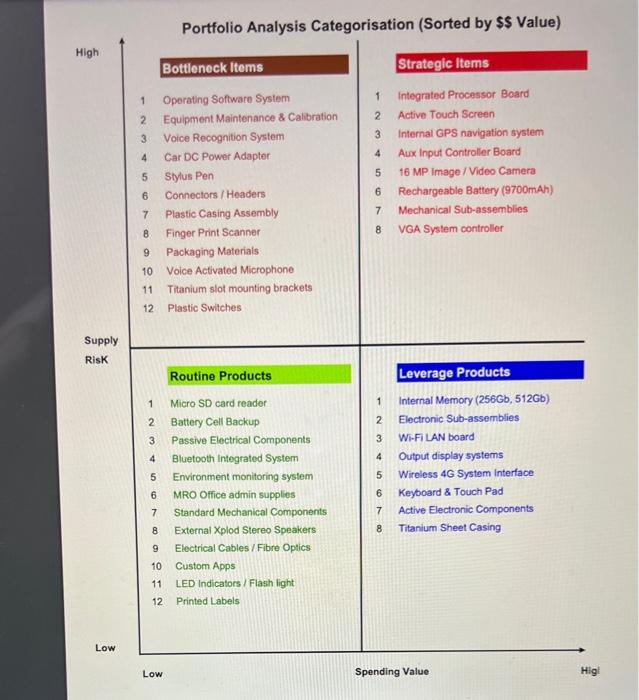

Discussion Questions You have been hired as a consultant for ART. Your task is to analyse their procurement operations and help them improve. a) Use the purchasing-portfolio analysis to categorise the various commodities / products purchased by the buyers in the Singapore procurement team. (10 marks) b) Comment on the current allocation of the commodities to the Buyers / Senior Buyers and determine whether the workload is distributed fairly. (Hint: Sort the commodities using the buyer as the primary sorting factor to determine the portfolio of the commodities that they are currently responsible). Alternatively, you may want to use the summary template given in the spreadsheet to present your answer. (10 marks) c) Analyse the supplier categories (purchase yalue, portfolio category \& buyer allocation). Comment on the various categories of commudities. Are you able to determine the level of difficulty (or ease) in managing the various categories (Hint: Sort the commodities using the category as the primary sorting factor to determine their portfolio category and then the buyers that are assigned to them). Alternatively, you may want to use the summary template given in the spreadsheet to present your answer. (15 marks) d) Based on the information given in the case study and the analysis of the data, can you identify any major problems in the procurement operations of ART. (15 marks) Business Overview and Structure of Organisation ART Pte Lid is a multi-national company (MNC) with headquarters in Houston (Texas, USA). Its main business is in the production and supply of tablet computers. ART is currently operating in 3 sites that have manufacturing operations and the necessary supporting functionai departments such as Planning. Procurement, Production, Engineering, Quality Assurance, Warehouse and Transportation. The headquarters in Houston is headed by the CEO, Tim Mason. The other 2 operational sites in Singapore and China are headed by their respective Operations Directors, Steven Soh and Calvin Chen respectively. Product Development \& Manufacturing Operations ART has been focusing on producing tablet computers. With a strong R\&D team, they have been leading the market with their sleek design, advance functions, long battery life and highresolution camera image. All the new models are developed at the R\&D department in Houston plant. The initial prototype build, plot-run and pre-productions test builds are then completed within the Houston plant. These are done to primarily evaluate and resolve any manufacturing and procest issues. Once the design and process are stabilised, the new products are transferred and manufactured in either one or both manufacturing facilities (in Singapore and China) based on market demand volume. All the 3 manufacturing sites have their own purchasing departments. The purchasing department in Houston is fully responsible to purchase materials for all new products during the design, prototype and pre-production builds. The buyers in Singapore and China generally do not get involved in purchasing during this product development stage. They will only start to source and initiate purchase when these new products are transferred to their respective operational facilities. All the 3 purchasing departments are given the jurisdiction to decide on the suppliers they use but cost and quality remain top criteria in selecting suppliers. Generally, the purchasing sites do not share the same AVL for their purchases. They purchase the commodities independently so even though the items are the same, each may utilise different suppliers. The purchasing operation in Singapore is headed by Stella Sim. Her department (purchasing) is responsible for all material purchases to support the Singapore manufacturing plant. The total annual purchases of materials and components amount to $10,560,000 (refer to Appendix A). The Purchasing Operations Department consist of 2 Senior Buyers, 4 Buyers, 2 Purchasing Assistants, 3 Planners and 1 clerical support (refer to organisation chart on the next page). All the buyers are currently fully responsible for the entire range of purchasing activities ranging from the selection of suppliers, negotiation of contracts, issue of purchase orders, expediting and monitoring of supplier performance (Appendix A indicates the allocatibn of commodities of these buyers). The 2 Purchasing Assistants (PAs) currently do not handle any purchase of commodities. They only support the Buyers \& Senior Buyers in any expediting or admin tasks. The current role of the Material Planners is to manage the company's inventory and plan for the quantity of materials required to be purchased for all items manufactured in the Singapore Operations. Fig 1 - Organisation Chart of SGP Purchasing Operations ART operations in Singapore currently utilises about 30% of local suppliers and 70% overseas suppliers. Many of the overseas suppliers were sourced and qualified by the buyers in Houston. The Buyers in Singapore had simply taken over the purchase of the items from the buyers from Houston when the project was transferred because they had no time to source for new suppliers. These suppliers may not be reliable but the buyers in Singapore continued to purchase from them. The buyers are found to be spending considerable time resolving daily supplier delivery issues. In an average month, the purchasing department processes about 1000 POs. The purchasing records reveal an average of 150 change orders per month due to changes in request dates or in purchase quantity. Many of these changes are last minute requests from the manufacturing plant and the lead time required are generally shorter than what was quoted by suppliers. The suppliers have also complained of the difficulty in meeting these change requirements and as a result, 20% of the deliveries are late. ART Singapore also encountered many quality problems from the suppliers where approximately 15% of the materials received are rejected at incoming inspection. The Singapore buyers are too busy to conduct regular performance review with the suppliers or to engage in cost reduction initiatives. It was also found that some of the suppliers were confused because of conflicting information received from more than 1 buyer on the same i.ms. Communication between Buyers, Planners and Suppliers All the planners within the respective sites are fully responsible for "internal expediting (within the factory)" and management of the material once it is received in the factory's incoming store. Planners are currently not allowed to communicate directly with the suppliers to prevent confusion. As such they are totally reliant on the buyers to update them on material delivery status from the suppliers. Buyers in Singapore are required to regularly keep the planners informed of the delivery status of outstanding materials via email. However, most of the time, the buyers are so busy that they do not have enough time to expedite and fail to keep the planners informed of the delivery schedules of the purchased items. Because the planners do not have any first-hand knowledge of supplier's capacity constraints, they have difficulties planning and forecasting material. The Operations Director of China (Calvin) has been complaining to Stella in Singapore because of the competition among their respective buyers. He indicated that on many occasions, 2 buyers (from different sites) are expediting the same suppliers for the same items which were needed by their respective operations. He even cited situations where buyers were competing for the same items from the supplier even though one site already had sufficient inventory. He asked Stella if there was any opportunity for the buyers in the 3 sites to work and purchase together. Appendix A : List of Purchases and Buyer Responsibiliy nawsalian Analueie Catannrisation (Sorted bv SS Value) Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock