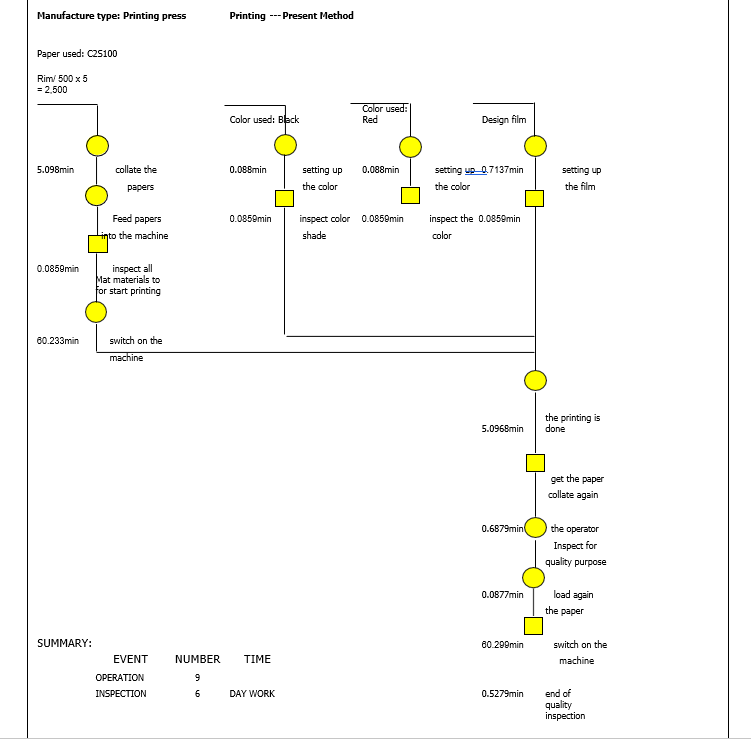

Question: Based on the Present Operation Process Chart below, analyze, examine, modify and establish an Improved Operation Process Chart proposal. Give the following based on the

Based on the Present Operation Process Chart below, analyze, examine, modify and establish an Improved Operation Process Chart proposal.

Give the following based on the chart above:

Data and Results Data Analysis and Conclusion

Improved Processed Chart

1. Objective(s): The activity aims to introduce the concepts and importance of the operation process chartin the improvement of processes. 2. Intended Learning Outcomes (ILOs): The students shall be able to: 21 Illustrate the improvement of a given problem through operation process chart. 22 Determine the limitations of the operations process chart. 23 Articulate that rearranging operations will result into savings 3. Discussion: The operation process chart shows the chronological sequence of all the operations, inspections, time allowances and materials used in a manufacturing or business process, from the arrival of raw material to the packaging of the finished product. The chart depicts the entrance of all components and subassemblies to the main assembly. The operation process chart displays manufacturing and business details at a glance. Two symbols are used in constructing the operation process chart: A small circle, usually 3/8 inch in diameter (denotes an operation) - takes place when a part being studied is intentionally transformed or when it is being studied or planned prior to productive work being performed on it. A small square, usually 3/8 inch on a side (denotes an inspection) - takes place when the part is being examined to determine its conformity to a standard. The operation process chart indicates the general flow of all components in a product, and since each step is shown in its proper chronological sequence, the chart in itself is an ideal plant layout. Consequently, methods analysts, plant layout engineers, and persons in related fields find this tool extremely helpful in developing new layouts and improving existing ones. 4. Resources: Case Study # 1: "Printing Press Operation Process" 5. Procedure: Based on the Present Operation Process Chart" below, analyze, examine, modify and establish an Improved Operation Process Chart proposal. Manufacture type: Printing press Printing ---Present Method Paper used: C25100 Rim/ 500 x 5 = 2.500 Color used: Red Color used: Black Design film 5.098min collate the 0.088min 0.088min setting up 0.7137min setting up setting up the color papers the color the film Feed papers 0.0850min inspect color 0.0850min inspect the 0.0850min into the machine shade color 0.0859min inspect all Mat materials to for start printing 80.233min switch on the machine the printing is done 5.0968min get the paper collate again 0.6879min the operator Inspect for quality purpose 0.0877min load again the paper SUMMARY: 60.299min switch on the EVENT NUMBER TIME machine OPERATION 9 INSPECTION 6 DAY WORK 0.5279min end of quality inspection

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts