Question: build and set up model base on Flexsim If the daily demands of products A, B and C are 1200-1500, 1000-1300 and 700-1000, respectively, considering

build and set up model base on Flexsim

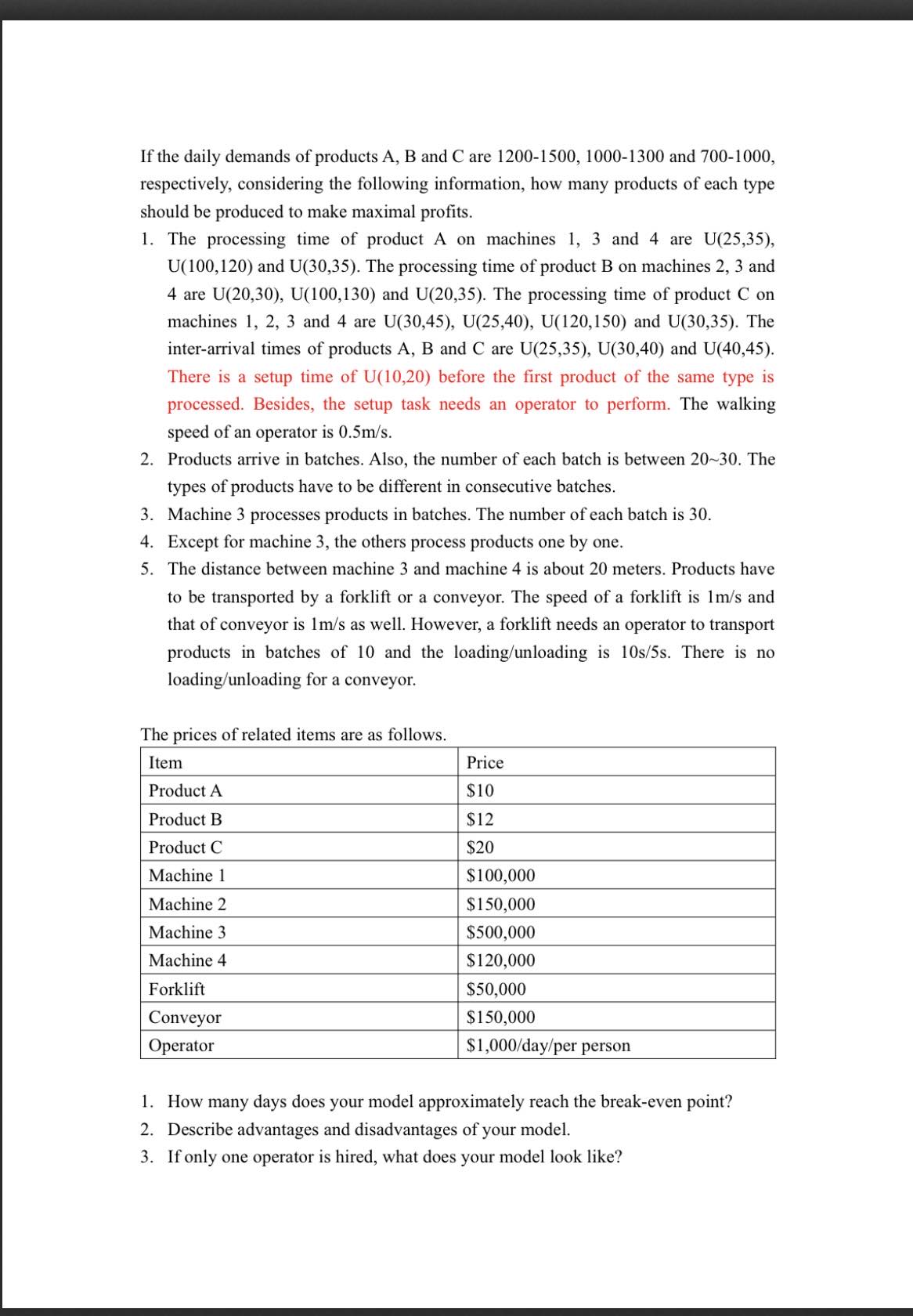

If the daily demands of products A, B and C are 1200-1500, 1000-1300 and 700-1000, respectively, considering the following information, how many products of each type should be produced to make maximal profits. 1. The processing time of product A on machines 1,3 and 4 are U(25,35), U(100,120) and U(30,35). The processing time of product B on machines 2,3 and 4 are U(20,30),U(100,130) and U(20,35). The processing time of product C on machines 1,2,3 and 4 are U(30,45),U(25,40),U(120,150) and U(30,35). The inter-arrival times of products A,B and C are U(25,35),U(30,40) and U(40,45). There is a setup time of U(10,20) before the first product of the same type is processed. Besides, the setup task needs an operator to perform. The walking speed of an operator is 0.5m/s. 2. Products arrive in batches. Also, the number of each batch is between 20 30. The types of products have to be different in consecutive batches. 3. Machine 3 processes products in batches. The number of each batch is 30 . 4. Except for machine 3, the others process products one by one. 5. The distance between machine 3 and machine 4 is about 20 meters. Products have to be transported by a forklift or a conveyor. The speed of a forklift is 1m/s and that of conveyor is 1m/s as well. However, a forklift needs an operator to transport products in batches of 10 and the loading/unloading is 10s/5s. There is no loading/unloading for a conveyor. The vrices of related items are as follows. 1. How many days does your model approximately reach the break-even point? 2. Describe advantages and disadvantages of your model. 3. If only one operator is hired, what does your model look like

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts