Question: by a recent pilot study producing the activity-based data). Unit-based system: Variable conversion activity rate: $100 per direct labor hour Material usage rate: $20 per

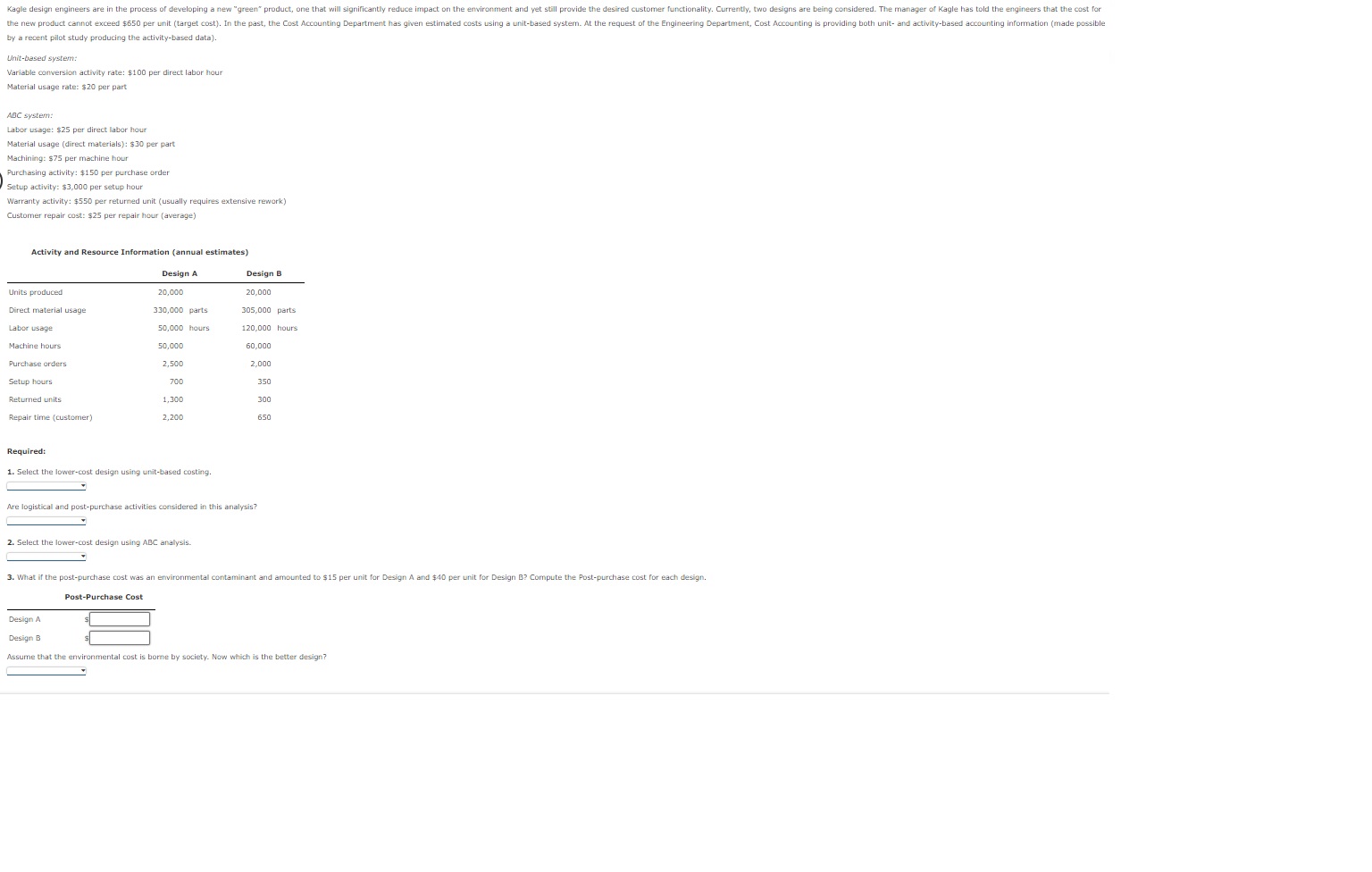

by a recent pilot study producing the activity-based data). Unit-based system: Variable conversion activity rate: $100 per direct labor hour Material usage rate: $20 per part ABC system: Labor usage: $25 per direct labor hour Material usage (direct materials): $30 per part Machining: $75 per machine hour Purchasing activity: $150 per purchase order Setup activity: $3,000 per setup hour Warranty activity: $550 per returned unit (usually requires extensive rework) Customer repair cost: $25 per repair hour (average) Artivitu and Rasnurep Information fannual astimates Required: 1. Gelert the Inwar-mst design using unit-based costing. Are logistical and post-purchase activities considered in this analysis? ?. 2. Select the lower-cost design using ABC analysis. 3. What if the post-purchase cost was an environmental contaminant and amounted to $15 per unit for Design A and q40 per unit for Design B? Compute the Post-purchase cost for each design. Assume that the environmental cost is borne by society. Now which is the better design

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts