Question: By using Arena Simulation A production system is designed to process two types of products Type 1 and Type 2. Type 1 arrives from a

By using Arena Simulation

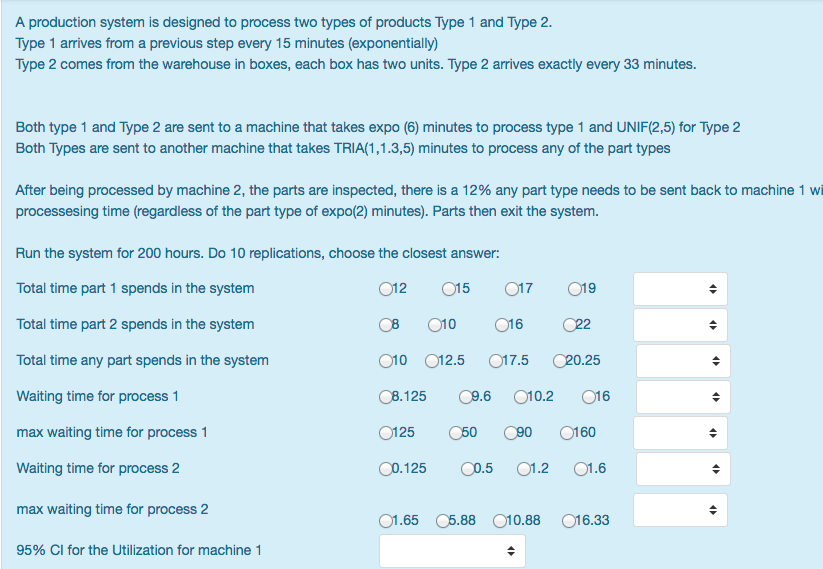

A production system is designed to process two types of products Type 1 and Type 2. Type 1 arrives from a previous step every 15 minutes (exponentially) Type 2 comes from the warehouse in boxes, each box has two units. Type 2 arrives exactly every 33 minutes. Both type 1 and Type 2 are sent to a machine that takes expo (6) minutes to process type 1 and UNIF(2,5) for Type 2 Both Types are sent to another machine that takes TRIA(1,1.3,5) minutes to process any of the part types After being processed by machine 2, the parts are inspected, there is a 12% any part type needs to be sent back to machine 1 wi processesing time (regardless of the part type of expo(2) minutes). Parts then exit the system. Run the system for 200 hours. Do 10 replications, choose the closest answer: Total time part 1 spends in the system 012 015 017 019 Total time part 2 spends in the system 08 010 016 C22 Total time any part spends in the system 010 012.5 17.5 20.25 Waiting time for process 1 08.125 0.6 010. 2 016 max waiting time for process 1 0125 050 090 0160 Waiting time for process 2 00.125 00.5 01.2 01.6 max waiting time for process 2 01.65 06.88 010.88 016.33 95% Cl for the Utilization for machine 1 95% CI for the Utilization for machine 2 The number of parts sent for reprocessing 0300 0250 200 0150 parts A production system is designed to process two types of products Type 1 and Type 2. Type 1 arrives from a previous step every 15 minutes (exponentially) Type 2 comes from the warehouse in boxes, each box has two units. Type 2 arrives exactly every 33 minutes. Both type 1 and Type 2 are sent to a machine that takes expo (6) minutes to process type 1 and UNIF(2,5) for Type 2 Both Types are sent to another machine that takes TRIA(1,1.3,5) minutes to process any of the part types After being processed by machine 2, the parts are inspected, there is a 12% any part type needs to be sent back to machine 1 wi processesing time (regardless of the part type of expo(2) minutes). Parts then exit the system. Run the system for 200 hours. Do 10 replications, choose the closest answer: Total time part 1 spends in the system 012 015 017 019 Total time part 2 spends in the system 08 010 016 C22 Total time any part spends in the system 010 012.5 17.5 20.25 Waiting time for process 1 08.125 0.6 010. 2 016 max waiting time for process 1 0125 050 090 0160 Waiting time for process 2 00.125 00.5 01.2 01.6 max waiting time for process 2 01.65 06.88 010.88 016.33 95% Cl for the Utilization for machine 1 95% CI for the Utilization for machine 2 The number of parts sent for reprocessing 0300 0250 200 0150 partsStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock