Question: Calculate the Process Capability Ratios: Cp, Cpu, Cpl, Cpk. Calculate the short term, Zst, and long term, Zlt, sigma levels. Upload your calculations in question

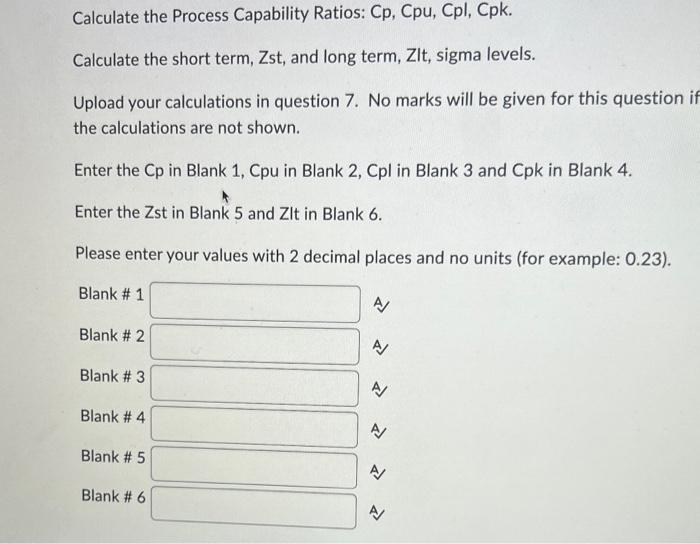

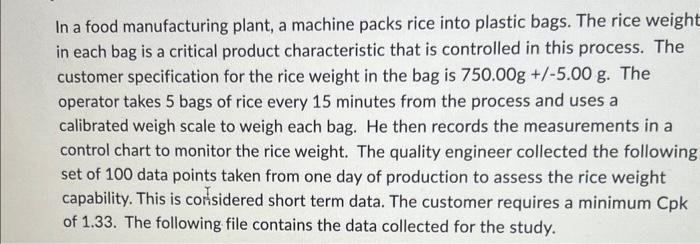

Calculate the Process Capability Ratios: Cp, Cpu, Cpl, Cpk. Calculate the short term, Zst, and long term, Zlt, sigma levels. Upload your calculations in question 7. No marks will be given for this question the calculations are not shown. Enter the Cp in Blank 1, Cpu in Blank 2, Cpl in Blank 3 and Cpk in Blank 4. Enter the Zst in Blank 5 and Zlt in Blank 6. Please enter your values with 2 decimal places and no units (for example: 0.23 ). Blank \# 1 Blank \# 2 A Blank \# 3 A Blank \# 4 Blank \# 5 Blank \# 6 In a food manufacturing plant, a machine packs rice into plastic bags. The rice weight in each bag is a critical product characteristic that is controlled in this process. The customer specification for the rice weight in the bag is 750.00g+/5.00g. The operator takes 5 bags of rice every 15 minutes from the process and uses a calibrated weigh scale to weigh each bag. He then records the measurements in a control chart to monitor the rice weight. The quality engineer collected the following set of 100 data points taken from one day of production to assess the rice weight capability. This is corisidered short term data. The customer requires a minimum Cpk of 1.33. The following file contains the data collected for the study. Calculate the Process Capability Ratios: Cp, Cpu, Cpl, Cpk. Calculate the short term, Zst, and long term, Zlt, sigma levels. Upload your calculations in question 7. No marks will be given for this question the calculations are not shown. Enter the Cp in Blank 1, Cpu in Blank 2, Cpl in Blank 3 and Cpk in Blank 4. Enter the Zst in Blank 5 and Zlt in Blank 6. Please enter your values with 2 decimal places and no units (for example: 0.23 ). Blank \# 1 Blank \# 2 A Blank \# 3 A Blank \# 4 Blank \# 5 Blank \# 6 In a food manufacturing plant, a machine packs rice into plastic bags. The rice weight in each bag is a critical product characteristic that is controlled in this process. The customer specification for the rice weight in the bag is 750.00g+/5.00g. The operator takes 5 bags of rice every 15 minutes from the process and uses a calibrated weigh scale to weigh each bag. He then records the measurements in a control chart to monitor the rice weight. The quality engineer collected the following set of 100 data points taken from one day of production to assess the rice weight capability. This is corisidered short term data. The customer requires a minimum Cpk of 1.33. The following file contains the data collected for the study