Question: Can someone help me with this question, I seen it answer but yet I do not understand. Managing Bottlenecks in Manufacturing Processes 4. Canine Kernels

Can someone help me with this question, I seen it answer but yet I do not understand.

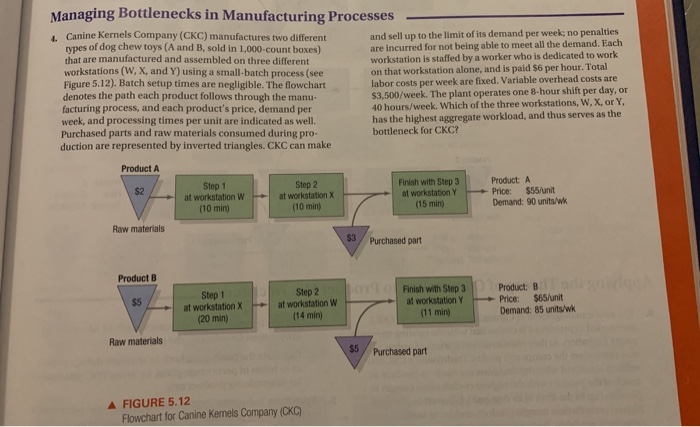

Managing Bottlenecks in Manufacturing Processes 4. Canine Kernels Company (CKC) manufactures two different and sell up to the limit of its demand per week; no penalties types of dog chew toys (A and B, sold in 1,000-count boxes) are incurred for not being able to meet all the demand. Each that are manufactured and assembled on three different workstation is staffed by a worker who is dedicated to work workstations (W, X, and Y) using a small batch process (see on that workstation alone, and is paid $6 per hour. Total Figure 5.12). Batch setup times are negligible. The flowchart labor costs per week are fixed. Variable overhead costs are denotes the path each product follows through the manu- $3,500/week. The plant operates one 8-hour shift per day, or facturing process, and each product's price, demand per 40 hours/week. Which of the three workstations, W, X, or Y, week, and processing times per unit are indicated as well. has the highest aggregate workload, and thus serves as the Purchased parts and raw materials consumed during pro- bottleneck for CKC? duction are represented by inverted triangles. CKC can make Product A $2 Step 1 at workstation W (10 min) Step 2 at workstation X (10 min) Finish with Step 3 at workstation Y (15 min) Product A Price: $55/unit Demand: 90 units/wk Raw materials $3 Purchased part Product B $5 Step 1 Step 2 at workstation W (14 min) Finish with Step 3 at workstation Y (11 min Product B Price: $65/unit Demand: 85 units/wk at workstation X (20 min) Raw materials $5 Purchased part A FIGURE 5.12 Flowchart for Canine Kernels Company (CKC)Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts