Please help this question asap. Thank you so much.

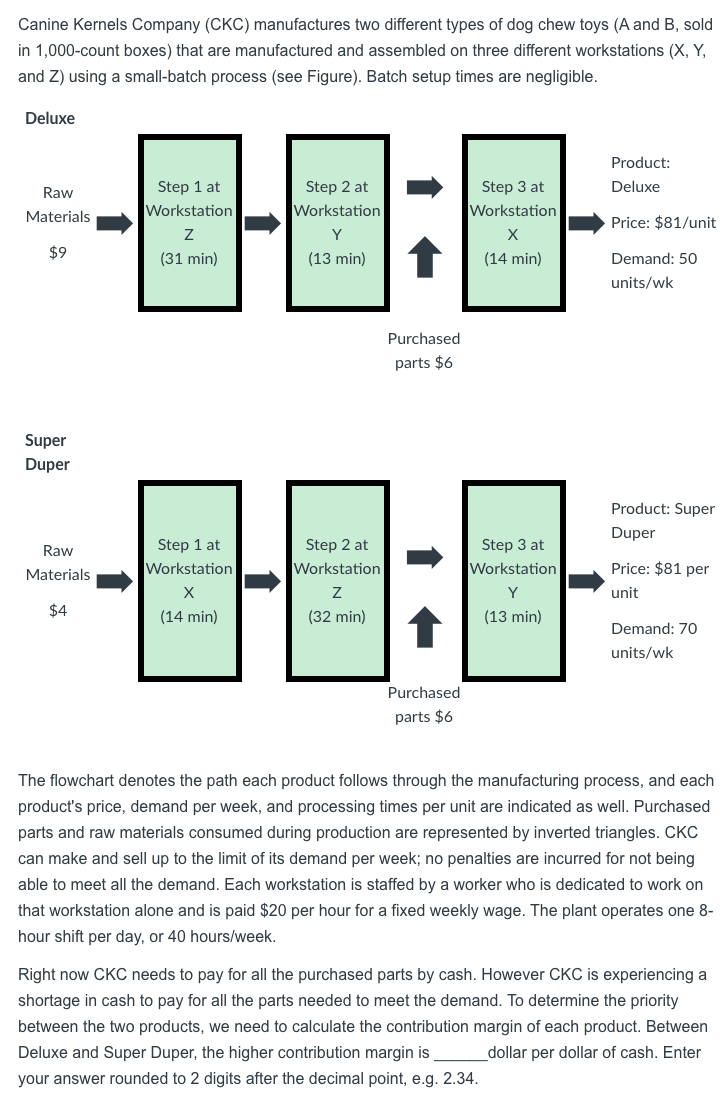

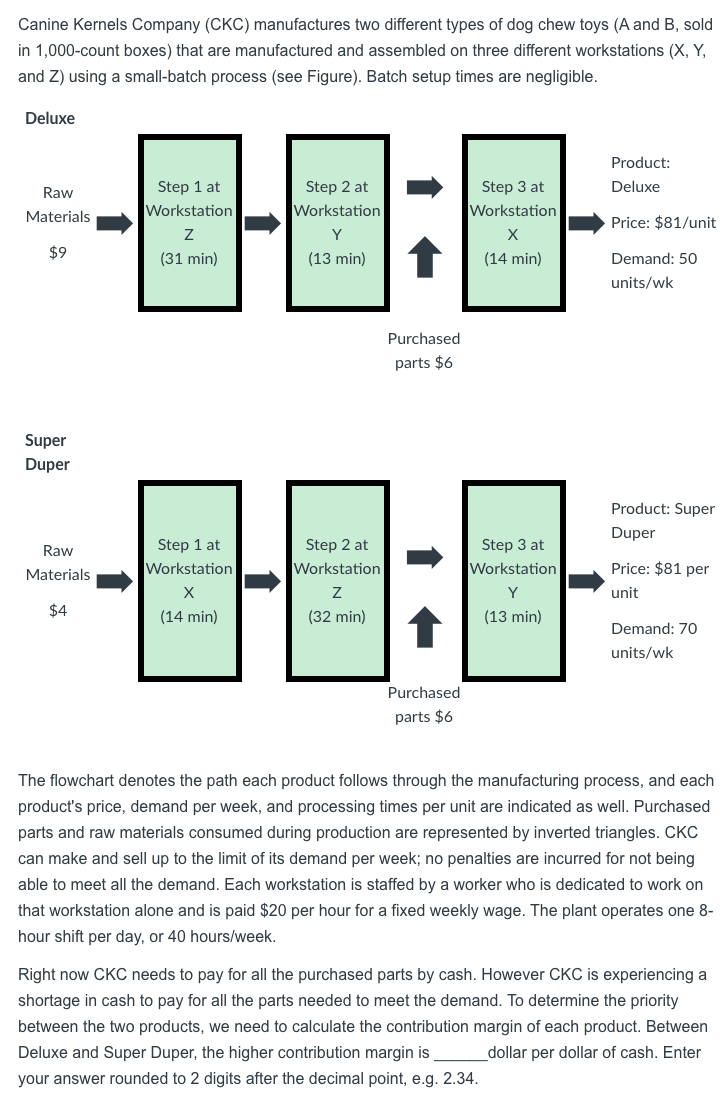

Canine Kernels Company (CKC) manufactures two different types of dog chew toys (A and B, sold in 1,000-count boxes) that are manufactured and assembled on three different workstations (X, Y, and Z) using a small-batch process (see Figure). Batch setup times are negligible. Deluxe Product: Deluxe Raw Materials Step 2 at Workstation Step 1 at Workstation Z (31 min) Step 3 at Workstation X (14 min) Price: $81/unit $9 (13 min) Demand: 50 units/wk Purchased parts $6 Super Duper Product: Super Duper Raw Materials Step 1 at Workstation (14 min) Step 2 at Workstation Z (32 min) Step 3 at Workstation Y Price: $81 per unit $4 (13 min) Demand: 70 units/wk Purchased parts $6 The flowchart denotes the path each product follows through the manufacturing process, and each product's price, demand per week, and processing times per unit are indicated as well. Purchased parts and raw materials consumed during production are represented by inverted triangles. CKC can make and sell up to the limit of its demand per week; no penalties are incurred for not being able to meet all the demand. Each workstation is staffed by a worker who is dedicated to work on that workstation alone and is paid $20 per hour for a fixed weekly wage. The plant operates one 8- hour shift per day, or 40 hours/week. Right now CKC needs to pay for all the purchased parts by cash. However CKC is experiencing a shortage in cash to pay for all the parts needed to meet the demand. To determine the priority between the two products, we need to calculate the contribution margin of each product. Between Deluxe and Super Duper, the higher contribution margin is dollar per dollar of cash. Enter your answer rounded to 2 digits after the decimal point, e.g. 2.34. Canine Kernels Company (CKC) manufactures two different types of dog chew toys (A and B, sold in 1,000-count boxes) that are manufactured and assembled on three different workstations (X, Y, and Z) using a small-batch process (see Figure). Batch setup times are negligible. Deluxe Product: Deluxe Raw Materials Step 2 at Workstation Step 1 at Workstation Z (31 min) Step 3 at Workstation X (14 min) Price: $81/unit $9 (13 min) Demand: 50 units/wk Purchased parts $6 Super Duper Product: Super Duper Raw Materials Step 1 at Workstation (14 min) Step 2 at Workstation Z (32 min) Step 3 at Workstation Y Price: $81 per unit $4 (13 min) Demand: 70 units/wk Purchased parts $6 The flowchart denotes the path each product follows through the manufacturing process, and each product's price, demand per week, and processing times per unit are indicated as well. Purchased parts and raw materials consumed during production are represented by inverted triangles. CKC can make and sell up to the limit of its demand per week; no penalties are incurred for not being able to meet all the demand. Each workstation is staffed by a worker who is dedicated to work on that workstation alone and is paid $20 per hour for a fixed weekly wage. The plant operates one 8- hour shift per day, or 40 hours/week. Right now CKC needs to pay for all the purchased parts by cash. However CKC is experiencing a shortage in cash to pay for all the parts needed to meet the demand. To determine the priority between the two products, we need to calculate the contribution margin of each product. Between Deluxe and Super Duper, the higher contribution margin is dollar per dollar of cash. Enter your answer rounded to 2 digits after the decimal point, e.g. 2.34