Question: Can someone please help and show steps with formulas?! Thanks! Two 180-horsepower (HP) motors are being considered for installation at a municipal sewage-treatment plant. The

Can someone please help and show steps with formulas?! Thanks!

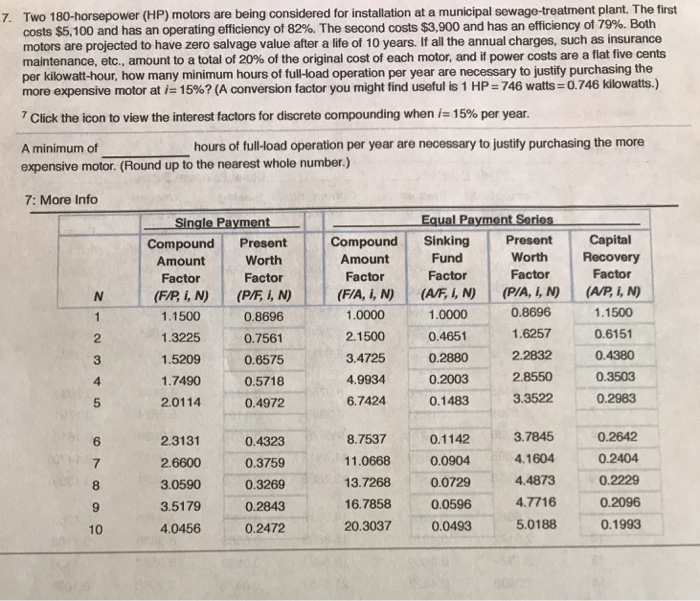

Can someone please help and show steps with formulas?! Thanks! Two 180-horsepower (HP) motors are being considered for installation at a municipal sewage-treatment plant. The first costs $5, 100 and has an operating efficiency of 82%. The second costs $3, 900 and has an efficiency of 79%. Both motors are projected to have zero salvage value after a life of 10 years. If all the annual charges, such as insurance maintenance, etc., amount to a total of 20% of the original cost of each motor, and if power costs are a flat five cents per kilowatt-hour, how many minimum hours of full-load operation per year are necessary to justify purchasing the more expensive motor at i = 15%? (A conversion factor you might find useful is 1 HP = 746 watts = 0.746 kilowatts.) Click the icon to view the interest factors for discrete compounding when i = 15% per year. A minimum of ___ hours of full-load operation per year are necessary to justify purchasing the more expensive motor. (Round up to the nearest whole number.)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts