Question: can someone please help with these two questions??? I attached the case study information from the two questions. please help. Discussion Questions The company's production

can someone please help with these two questions??? I attached the case study information from the two questions. please help.

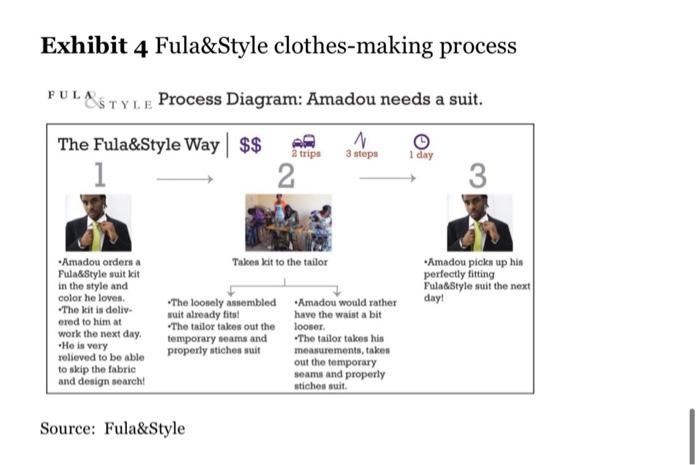

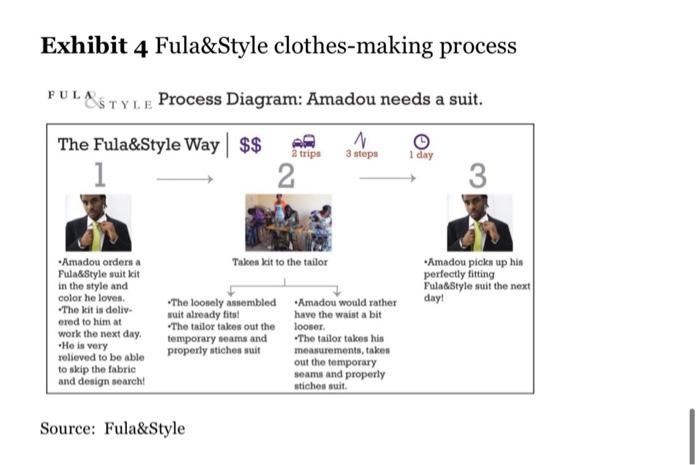

Discussion Questions The company's production approach occupies a position between make-to-stock and make-to-order. Discuss the pros and cons of these three approaches to production for this enterprise. Kane aimed to "win in the middle of the income pyramid. Her fellow students at MIT viewed this strategy as questionable. What do you think? Explain your answer. A Different Business Model The vast majority of clothes sold in developed countries were products of a make-to-stock production model in which clothing firms designed pieces in a spectrum of sizes, had them sewn in large quantities in countries with low labor costs, and then pushed them out through their retail channels. Customized, tailor-made clothing followed a make-to-order model. Kane and Badger conceived an approach that stood between mass production and individual customization, adopting beneficial elements of each model. Fula&Style would sell boxed "kits" of preassembled, 80-percent sewn fabrics, including zippers, buttons, matching accessories, and clear instructions for the tailor. Customers would take those kits to their favorite tailor, who could complete the production cycle: fitting and sewing (Exhibit 4). The result would be a piece of apparel that fit perfectly yet demanded less of the customer's time and effort than the traditional tailor-made alternative. The suppliers for this alternative kit model-tailors and fabric makers-were plentiful and affordable throughout West Africa. If Fula&Style were successful, these tailors and local fabric makers would also benefit. Kane and Badger considered the betterment of these suppliers as part of Fula&Style's mission. Among Senegalese tailors there were no uniform standards for how pieces should be fitted and sewn together or the number of stitches per centimeter. The absence of standards was a potential threat to the quality and consistency of the new company's offerings. Fula&Style could design in such a way that each kit would contain clear instructions. But would independent tailors follow them to the letter? Would competitors copy their kit-based concept? Like other MIT students, Kane and Badger explained their idea to classmates, hoping for useful feedback. They got some good ideas from classmates, but found most of these discussions frustrating. Kane recalled, "They'd say, "To be successful you have to address either the very bottom or very top of the pyramid. You can't win in the middle." Kane rejected that Page 4 Fula Style Case 14-006 conventional thinking and felt that in addressing middle class needs, the venture would create jobs for people at the pyramid's bottom. The MIT Contest Given mixed feedback from their peers, the two students wondered if they were too close to their concept to perceive inherent weaknesses? Could those be improved? One way to find out was to present the company's business plan to more critical eyes and ask for feedback. The MIT Ideas Global Challenge provided an opportunity to do that. The MIT Ideas Global Challenge supported innovation and entrepreneurship through an annual competition that awarded up to $10,000 USD per team for the best ideas for tackling barriers to human or environmental well-being in communities around the world. The contest was open to MIT students, faculty, staff, alumni, and their collaborators. From 2001 to 2012 the challenge had awarded more than $400,000 to about 75 teams. Collectively, those teams had secured $3.2 million in follow-on funding for their projects, which aimed to serve people in 28 countries. Kane and Badger submitted their idea for Fula&Style. The judges had reservations about the concept, which they perceived as more of a craft business, something the entrepreneurs would be unable to scale up. The judges also did not think their plan for sourcing within Africa was a good one. They didn't get it, Kane complained later. "We found that frustrating, but their negative response made us realize that we needed to change our pitch and make our intentions more clear. They resubmitted their improved plan and to their delight, received a $7.500 award, which became the enterprise's initial capital. Those funds, plus more from friends and family, were used in the summer of 2012 to rent a small shop in Dakar, Senegal, hire five summer interns (Kane's cousins), manufacture a modest inventory, print a small product catalog, and stage a fashion show of Fula&Style apparel. A trickle of sales began immediately, providing additional cash. Help was also offered by Air Senegal, which gave the enterprise three free round-trip travel tickets. Four other companies supported the venture with nonmonetary help, Kane's mother also pitched in, sending the team lunches every day for a month. The two months Kane spent in Senegal during the summer of 2012 were busy ones, packed with learning experiences. She had a full agenda: Design and produce a prototype men's suit and shirt and a women's suit and dress Work on the brand and marketing strategy Test the prototypes and get feedback on how to improve them Test customer reactions to the marketing strategy Validate costs and pricing hypothesis Identify potential designers and suppliers of material (fabrie, threads, accessories) Identify the most appropriate distribution channels To further complicate her busy summer, Kane planned her wedding and honeymoon in Senegal during the January 2013 winter break. Badger, having graduated from Mrr's architectural school, returned to Africa that summer to pursue a career in architecture. Kane returned to MIT in autumn 2012 for her second and final year at MIt's Sloan School. With Badger gone, she recruited two new team members at MIT. Back in Senegal , Fula&Style had one full-time employee, with whom Kane kept in daily contact via Skype and other media. Page 5 Exhibit 4 Fula&Style clothes-making process FULA STYLE Process Diagram: Amadou needs a suit. The Fula&Style Way | $$ 1 3 stops 2 3 2 tripe 1 day Tales kit to the tailor Amadou picks up his perfectly fitting Pulastyle suit the next day! Amadou orders a Fula&Style suit kit in the style and color he loves The kit is deliv ered to him at work the next day He is very relieved to be able to skip the fabric and design search! "The loosely assembled Amadou would rather suit already fits! have the waist a bit "The tailor takes out the looser temporary teams and "The tailor takes his properly stiches vuit measurements, takes out the temporary seams and properly stiches suit Source: Fula&Style

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock