Question: can you please post how the final result looks on excel? A small firm makes three products (A, B, and C), which all follow the

can you please post how the final result looks on excel?

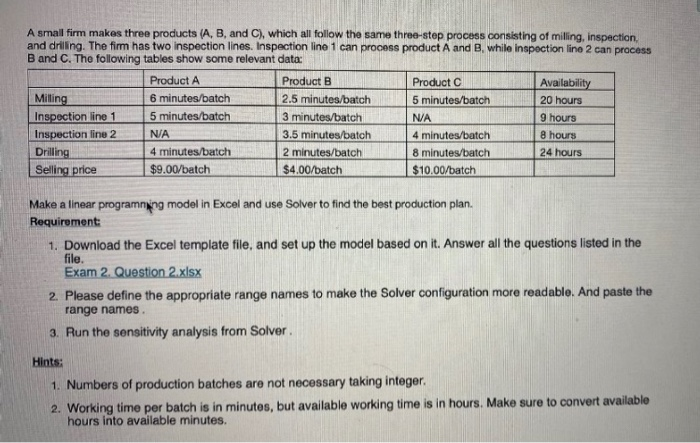

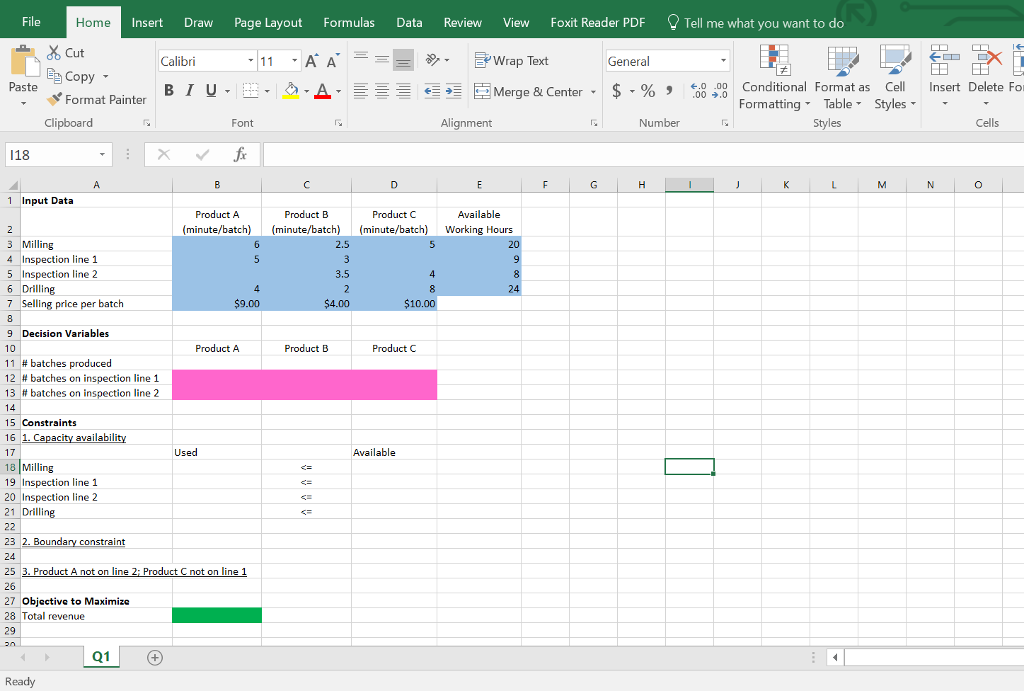

A small firm makes three products (A, B, and C), which all follow the same three-step process consisting of milling, inspection and drilling. The firm has two inspection lines. Inspection line 1 can process product A and B while inspection line 2 can process B and C. The following tables show some relevant data: Product A Product B Product C Availability Milling 6 minutes/batch 2.5 minutes/batch 5 minutes/batch 20 hours Inspection line 1 5 minutes/batch 3 minutes/batch NA 9 hours Inspection line 2 NA 3.5 minutes/batch 4 minutes/batch 8 hours Drilling 4 minutes/batch 2 minutes/batch 8 minutes/batch 24 hours Selling price $9.00/batch $4.00/batch $10.00/batch Make a linear programning model in Excel and use Solver to find the best production plan. Requirement: 1. Download the Excel template file, and set up the model based on it. Answer all the questions listed in the file. Exam 2. Question 2.xlsx 2. Please define the appropriate range names to make the Solver configuration more readable. And paste the range names 3. Run the sensitivity analysis from Solver Hints: 1. Numbers of production batches are not necessary taking integer. 2. Working time per batch is in minutes, but available working time is in hours. Make sure to convert available hours into available minutes. View Foxit Reader PDF Tell me what you want to do) 16 File Home Insert Draw Page Layout Formulas Data Review of Cut Calibri - 11 - AM Wrap Text General Eg Copy Paste BIU - A Merge & Center Format Painter Merge & Center - $ - %, Clipboard Font Alignment Number HH HH Insert Delete Fon 4.0.00 Conditional Format as Cell .00 .0 Formatting Table - Styles Styles Cells 118 fr C D E F G H 1 K M N 0 Product C (minute/batch) 5 Product B (minute/batch) 2.5 3 3.5 2 $4.00 Available Working Hours 20 9 8 24 4 8 $10.00 Product B Product A B 1 Input Data Product A 2 (minute/batch) 3 Milling 6 4 Inspection line 1 5 5 Inspection line 2 6 Drilling 4 7 Selling price per batch $9.00 8 9 Decision Variables 10 Product A 11 #batches produced 12 #batches on inspection line 1 13 #batches on inspection line 2 14 15 Constraints 16 1. Capacity availability 17 Used 18 Milling 19 Inspection line 1 20 Inspection line 2 21 Drilling 22 23 2. Boundary constraint 24 25 3. Product A not on line 2; Product C not on line 1 26 27 Objective to Maximize 28 Total revenue 29 Available Q1 + ReadyStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock